Reducing The Cost of Your PCB & Electronic Assembly

Are you REALLY saving money sub-contracting your assembly to a handful of vendors?

Subcontracting, can in the short term save you money on your assembly. However, rush and expedited shipping fees are killing your overall budget.

You need a simple solution.

Having your electronics box build project spread out among several electronic assembly vendors may seem great on paper, but it can also create a lot of unknowns. Time is an important commodity and is the #1 hidden cost in your overall assembly.

Introduction

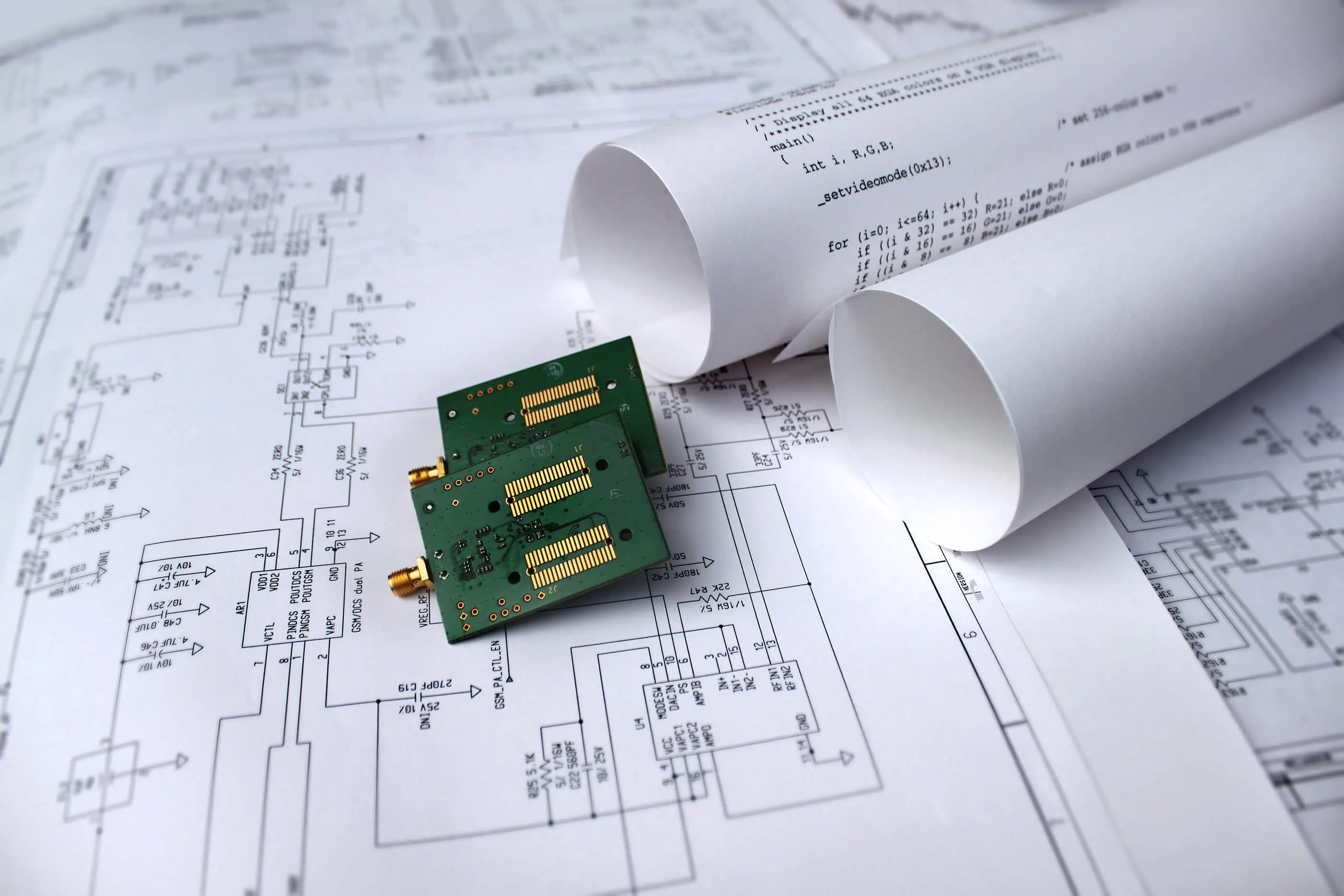

In your hand, on your desk, are the plans for The Next Big Thing. You have quotes. You have estimates. You’ve contacted a dozen different vendors. Places are lining up to help you get started on The Next Big Thing.

As a smart businessperson that knows good ideas don’t come cheap, you’ve been looking carefully at each of your options to get the best price for everything. On one hand, you could have one vendor do the whole thing. However, it looks like if you break up production, you could use each vendor’s least expensive parts and save overall.

After considering all your pros and cons, you’ve decided to break up your production. It saves costs, after all!

Here is the Plan:

- Vendor 1: Makes the Printed Circuit Boards

- Vendor 2: Connects the wires to the circuit boards.

- Vendor 3: Creates the final assembly.

- Vendor 4: Ships the product to the customers.

It sounds like a brilliant, low-cost plan. The Next Big Thing gets built and delivered to your customers for presumably the lowest cost. That’s a win, right?

Maybe. Maybe not.

Having your project spread out amongst many vendors may seem great on paper, but it can also create a lot of unknowns. You’ll want to consider the full cost of your mechanical assembly, including potential hiccups before fully committing to that piecemeal build.

You know that time is your most important commodity and, among other variables, this is the most likely hidden cost in your piecemeal build.

You know that time is your most important commodity and, among other variables, this is the most likely hidden cost in your piecemeal build.

The extra time when the boards and the wires don’t line up right and have to be redone. Time lost when the project needs adjustments and you have to work through all the previous vendors. More lag time when the shipping company doesn’t have the right packaging to protect your project.

You and The Next Big Thing deserve a better way that can cut down on these losses and potentially even save you money from the start.

What you need is a start-to-finish box build with one electronic contract manufacturer (ECM) that can reduce your shipping timelines, streamline your assembly process, and reduce your costs.

How can this be, you ask? How can a single source ECM compete with the cost savings you saw in your plan with multiple vendors?

The secret is in limiting too many hands and too many transitions. Single source ECMs like Levison Enterprises, promote cost savings by limiting the number of vendors and thus, limiting the number of “cooks in the kitchen.”

Why would too many “cooks” be a problem?

The Next Big Thing is complex, right? You’ve got detailed plans and have thought through the entire assembly process. At the same time, you know that it’s likely that design changes may need to be made as assembly gets started, possibly even after The Next Big Thing is in the manufacturing stage.

The Next Big Thing is complex, right? You’ve got detailed plans and have thought through the entire assembly process. At the same time, you know that it’s likely that design changes may need to be made as assembly gets started, possibly even after The Next Big Thing is in the manufacturing stage.

When those changes happen and your needs evolve, partnering with a single source ECM will allow you to make changes with one vendor instead of having to contact multiple places. With one vendor, you eliminate the potentially disastrous costs of miscommunication, and worse, lack of accountability somewhere in your mix of vendors.

Cost is a compelling decision point and the costs of “what-ifs” are difficult to determine. The following is intended to help you get the full picture of your costs and consider the potential losses in common “what-ifs” when it comes to electronic box builds.

What is a Box Build

A box build, or “complete assembly” entails all your project’s boards, wires, din rail, backplane assembly, and everything else to make your final piece. The box build is an electromechanical assembly process that includes everything from system and product assembly to configuration and testing to warehousing and shipping.

The end product is called a box build or a cabinet assembly that could look like a tiny enclosure connected to a user display or a complicated electromechanical assembly, complete with moving parts and sub-assemblies.

In a box build with a single source ECM, your design and production plans are all together at one location, keeping your project lean and with minimal risk. Through production and testing, your ECM’s advantages become yours, with in-sourced assemblies, access to partners or unique testing capabilities.

In a piecemeal assembly, design and production might be split among dozens of different locations. This allows you to potentially take advantage of a vendor’s low cost on specific parts of your assembly, but opens your project up to risk in communication and troubleshooting.

In either case, you are responsible for your bill of materials, CAD models, dimensions, testing requirements and possibly a sample unit, but the ECMs handle everything else that gets your product to the consumer.

What Are You Really Saving by Segmenting Your Build?

Even with the risks associated with segmenting your build, sometimes the siren song of cost savings still calls. No one is in business to throw more money at a project than necessary, so of course cost is going to weigh heavily into your decision.

Before you finalize the decision to segment, do take time to consider the real costs of a piecemeal build for your project.

Mistakes are the number one threat to your project in any type of build, but they are especially costly in a segmented build. If something doesn’t line up right, or the wrong grade of material is used, or someone skipped a step, you have to go down the long line of your production process to get the problem fixed. Every one of your vendors will likely pass the buck to the next.

Another cost threat is in 11th-hour changes. (Yeah, we know, those never happen.) Again, changes are likely in any kind of build, but when this happens in a piecemeal build, you will have to chase changes back through several different vendors, each now having to readjust their time frames. How far back into your production line and list of vendors are you willing to go to make the changes?

Whether it’s mistakes or last-minute changes, it all means a massive headache for you and a lagging production timeline for your project.

Further, a lagging production timeline for whatever reason means shipping delays. This is frustrating enough, but if late delivery isn’t an option, you’re likely looking at increased costs for expedited shipping.

Further, a lagging production timeline for whatever reason means shipping delays. This is frustrating enough, but if late delivery isn’t an option, you’re likely looking at increased costs for expedited shipping.

In a perfect build, with ideal manufacturing partners, maybe mistakes and changes would be minimal and easy. However, the more partners you add, the greater your chances of running into a costly mistake.

Are the potential cost savings still there when you consider the increase in risk?

An all-in-one electronic contract manufacturer relieves both of these potential threats. They know your project inside and out, making them nimble with changes on the fly that won’t affect your timeline. If there happens to be a mistake, they can quickly get to the root of it and make changes to the production line without having to work backward through a list of other vendors who aren’t interested in fixing the problem.

A single group of highly-trained people dedicated and working on your project means cost savings in materials, shipping and time. It means a transparent level of accountability. Most importantly, it means much less headache for you.

How Does an All-In-One Help My Design

Beyond reducing risks, use of an all-in-one ECM will produce a stronger design.

At all phases of your project, the all-in-one ECM has an advantage over a segmented plan due to the ability to see the entire project. In a segmented model, each ECM only knows its piece of the puzzle. What will happen if the design is flawed? Who will take ownership, and more importantly, who will track down the mistake and get it fixed?

Alternatively, an all-in-one ECM will know all your parts and how they work together. The all-in-one sees your entire project and can detect potential efficiencies or advantages as you finalize your design. With expert engineers on staff to look over the design, you get a second opinion on all your products, giving them better performance and efficiency.

As you work through your design process, you’ll encounter several other advantages with an all-in-one electronic contract manufacturer.

Bill of Materials

Once you’ve provided a complete bill of materials for your project, your all-in-one ECM can work with its trusted network of material vendors to obtain your parts. This may mean better prices, a better understanding of the parts, known quality and quality certifications, and the potential to order in bulk by leveraging the ECM’s buying power.

Rapid Prototyping

Sometimes you really need to see multiple versions of your concept and weigh your options before committing to final manufacturing and assembly. Rapid prototyping is another all-in-one ECM benefit for when you need to physically see a product before committing to your final decision.

Rapid prototyping from your ECM will use cutting edge technology and processes to create assemblies that drastically cut project lead time and the costs associated with traditional assemblies. A rapid prototype can provide highly complex model without any elaborate tooling, which saves you time, and streamlines your production processes.

Using this process, you can fix your project’s kinks through vigorous testing and compliance and not have to worry about full production until you’re sure it’s how you want it.

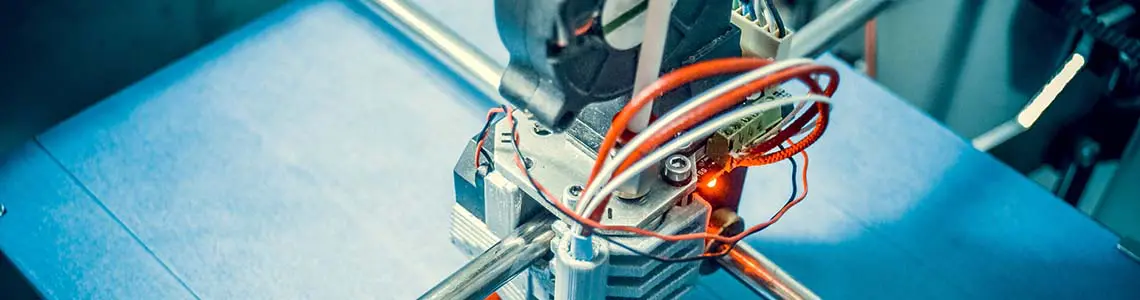

3D Printing

Another rapid prototyping method gaining in popularity is 3D printing. An all-in-one electronic contract manufacturer that offers 3D printing can optimize your prototyping process and maximize your savings.

3D printing is now one of the most popular prototyping choices because it offers fast fabrication and low material costs. Your ECM should be able to produce prototypes with shorter lead times and lower cost than traditional methods.

Project Team, Assemble

After pouring countless hours and energy into your project, you want to be sure that it is assembled with the same level of care you used to dream and design it. You and your project want and deserve that level of commitment to your project. You can count on it with a quality all-in-one ECM.

Project Manager

With an all-in-one ECM, your project will have a dedicated project manager overseeing your entire build. They will know the ins and outs of your project from design to final assembly and shipping. The dedicated project manager ensures the integrity of your project all the way through to getting it to the consumer.

Once your project is in its assembly phase, the project manager oversees the entire process. For example, let’s say your project will need in-house sub-assemblers to complete assembly for a PCB, cabling, and housing. Your project manager oversees the expert sub-assemblers getting it done to your exact specifications. Each sub-assembly part gets its own expert so your project is carefully put together. If at any time the project manager has a question about your build, the experts are right on hand to get questions handled and potential mistakes avoided.

Equipment

A good all-in-one ECM partner will be able to do all of your work, and do it well. You need a partner that can do SMT, through-hole technology, mixed flex circuit, and rigid flex technologies, while also keeping up-to-date on the latest technology.

If they have all the technology and processes you need, also consider whether or not the ECM can handle the full order of your project. After all, that’s the whole point of using an all-in-one ECM.

When it comes to the assembly itself, take a look at the work areas. Are they clean? What kind of technology have they invested to help meet the innovation needs of your projects? Can you take a tour of the facilities to see them in action? Basically, does your all-in-one ECM have the kind of space that not only meets your needs, but does it to your standards?

Experienced Team

Finally, for many projects, the quality of the assembly comes down to one thing: the people doing the work. Take a look at the kind of experience the ECM’s team has. Before they begin working on your project, check that they have the correct certifications and industry standards to work on your project.

Again, since you’re looking for an all-in-one solution, make sure the ECM’s team has a diverse project portfolio. A company that only works on one type of design is not your best option for a top level assembly or box build. You’re looking for a nimble and innovated team that can work in all kinds of areas including Industrial, Government, Mobility, Aerospace, Medical, and Food Safety.

Taking a careful look at the project management, equipment, and experience of your box build ECM will help ensure your expectations are met and your project is delivered on time.

Packaging And Shipping With Ease

Packaging and shipping are the steps that always need support from a sub-contractor. However, a good ECM partner will be willing and able to relieve this headache for you.

Packaging and shipping are the steps that always need support from a sub-contractor. However, a good ECM partner will be willing and able to relieve this headache for you.

You are making a substantial investment in your build and packaging and shipping is not the time to skimp on costs. You want to protect that investment the best way you can. This is where your all-in-one ECM becomes a huge time saver for you as they can keep your shipping costs down and ship directly to where your project needs to go.

Your ECM knows your build and its specs. The ECM also knows the regulations and shipping methods that will work best for your product. Don’t risk your investment by handing this over to shipping companies that may not have experience handling electronics or other sensitive equipment just to save a buck.

Not only does your all-in-one electronics manufacturer know your needs, but they know what the shipping companies need as well. Your electronics assembler should understand tonnage and work with shippers across the U.S.A. and world to help customers achieve low-cost, high-quality shipping solutions for their products.

Repairs Made Easy

When you’re focused on finding the right solution to design and assemble your box build, it’s hard to also think about what happens when this major investment eventually has a problem. Unfortunately, even the best quality projects don’t last forever. However, in the instance that your project needs support or repairs, an all-in-one ECM is still your best solution.

An all-in-one ECM knows your build. They helped you design it. They oversaw the manufacturing of each part and made sure it was assembled to your exact needs. No other place will be better equipped to identify technical issues when they arise.

As much as your all-in-one ECM is uniquely positioned to give you the best possible design, assembly, and shipping service, it’s also ideal for troubleshooting your product design and manufacturing issues.

With an electronics build to print manufacturer at the helm of your top-level assembly, the in-house team of engineers can quickly find the causes and solutions to any project issue. Whether it’s an entire product or a component part that needs repair, the people who built your project are going to be the fastest to find and fix the problem. Plus after the root cause is identified and every aspect of the repair is complete, your all-in-one ECM will ship it where it needs to go. All of this reduces your downtime and gets you back to what you do best.

No one wants to talk about a project breaking or malfunctioning, but to be realistic, you need to consider this in your plan. When choosing an all-in-one ECM, remember that a good ECM will stand behind their work. Ask about a warranty on your parts and assemblies. Make sure your ECM will repair your assembly and ship it back to you or directly to your end user.

Quality Certifications

Quality certifications are important to your ECM, and they should be to you too, even if your project doesn’t require it.

Quality certifications are important to your ECM, and they should be to you too, even if your project doesn’t require it.

The level and type of certifications your ECM maintains speak to how dedicated your ECM is. It’s easy for an ECM to say they are committed to quality. Demonstrating that commitment through high-standard certifications is another level of commitment. Quality certifications require continuous audits and training to maintain. They call for highly qualified staff that are dedicated to your project. Regardless of your project’s specific certification requirements, you should require this level of integrity for your project.

Certifications that are worth looking for are ISO, ITAR, and AS9100. The benefits of each add a layer of protection for you and for your product.

Why Choose Levison

Levison Enterprises is the nimble domestic all-in-one electronic contract manufacturer you’ve been looking for. We have extensive experience in creating box builds and handling all aspects of our clients’ projects from design to final assembly.

Our top-level assembly services include:

- Electro-Mechanical Assembly

- Electronic Control Panels

- Box Builds

- Electromechanical Builds

- DIN Rails and Backplanes

- Multi-Facet Assemblies

- Full System Testing

We have trained and skilled engineers with a background in design and programming. Our engineers can look over your design before production and find ways to save money on parts and your complete assembly.

Our dedicated staff know your project inside and out. You’ll get a dedicated project manager who oversees each phase of your project build and assembly. Each phase is headed by a sub-assembly manager who will design a team of expertly trained staff who become the authority on their phase of your build.

We also create unique ideas for shipping and fulfillment. Save money and let us handle fulfillment for your box build or cabinet assembly.

We stand behind our work and offer a warranty on our assemblies. We can easily make repairs on your project because we know your project inside and out. Levison Enterprises will work with you to make sure repairs are done quickly and right.

Our quality certifications set us apart from the competition. We take quality seriously strive for continuous improvement, making us more lean, efficient, and able to create your project with speed, but also a superior attention to detail.

Let Us Help You!

Levison Enterprises provides dedicated quality processes to produce reliable, critical to performance electronic integrated products through design support, comprehensive manufacturing solutions and collaborative client engagement.