Rapid Electronic Prototyping

We have the tools available to deliver a prototype at any level of complexity and can begin your prototype process from scratch or from an existing prototype design.

Levison Enterprises’ rapid electronic prototyping helps our clients create cost-effective designs with minimal chance of needing to redesign or redo, helping impress your potential investors with innovative ideas.

Prototyping is a necessary stage of the manufacturing process. After design and before production, there is a window where you, together with your electronic manufacturer, can take a thorough look at the design and components of your project. A prototype will allow your project to move from the theoretical stage to the concrete stage, and this is your opportunity to identify and address potential problems.

Our Electronic Prototyping Services

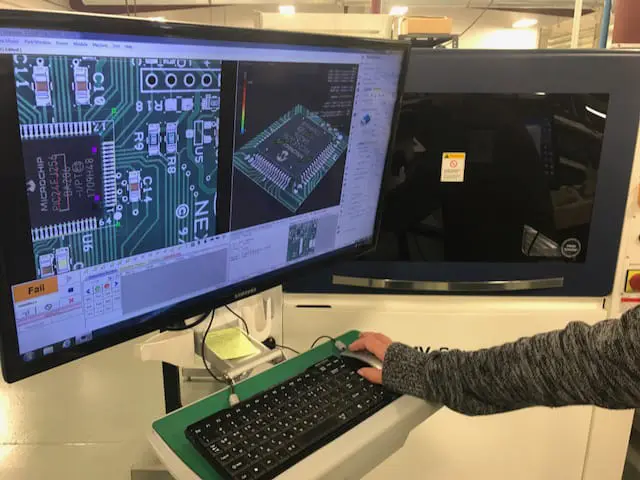

Computer-aided design (CAD) experts can deliver rapid prototyping through 3D printing for any size electronic project. Levison Enterprises focuses on effective, meaningful, and reliable communication to tweak and rework a prototype to make it the best product possible. When your prototype is created, you will be able to see the functionality and reliability that comes from internal and external quality audits throughout the development.

Computer-aided design (CAD) experts can deliver rapid prototyping through 3D printing for any size electronic project. Levison Enterprises focuses on effective, meaningful, and reliable communication to tweak and rework a prototype to make it the best product possible. When your prototype is created, you will be able to see the functionality and reliability that comes from internal and external quality audits throughout the development.

DFM Analysis Before Prototyping

DFM (Design for Manufacturing) analysis looks at your design from the eye of the manufacturer. Many designs look flawless at the theoretical stage, but will run into issues during production due to components selected, size, structure, or any number of features. Having our engineers perform a DFM analysis before prototyping ensures that you will not waste time and money on a prototype that will not be suitable for production, or worse, a production run of an inefficient product. DFM analysis looks at all the factors that will go into your product before prototyping, and can address the best practices for cost-effective, efficient, and quality manufacturing at the design stage.

Engineering Services for Prototyping

The services begin with prototyping pre-production. This is the time to make sure your design is how you envisioned it. In pre-production, you and your engineering team will check that all parts are available and can be sourced as necessary. Skipping this step can mean that a market change in parts availability can trip up your design. In the prototype production, you will see that the product is manufactured correctly and you have the right team who understands your product needs. Design errors will be identified and corrected, and another prototype may be created with those errors addressed. Only a PCB prototype can fully identify issues with design, functionality, and size. A PCB prototype will be thoroughly inspected.

Rapid Electronic Prototyping

Rapid electronic prototyping not only allows you to see your prototype faster, but will allow you to look at and compare several prototypes to determine the best fit for the production run. Rapid electronic prototyping doesn’t rely on casting, but instead makes use of CAD and 3D printing to produce a model for evaluation. With rapid electronic prototyping, you will know more quickly if your design needs to be adjusted before moving on through the production stage of product development.

Quality Certifications For Your Rapid Electronic Prototyping Manufacturer

The quality certifications held by Levison Enterprises demonstrate a continuous commitment to improvement and excellence. Although certain certifications are necessary for certain industries, all certifications demonstrate the high-quality standards and established processes Levison prides itself on. Our rapid prototyping ensures that we are using our expertise and commitment to excellence with every build.

Testing Done in House

Testing Done in House

At a turnkey facility, all testing is done in house. By committing to fulfilling all services under one roof, there will be no breakdown in communication that can result in errors or lost time that can delay production. In-house testing provides the results directly to the engineers who will be using that testing to tweak and adjust the design and components.

Finding the Right Electronic Prototyping Company

The right company to partner with is one that uses prototyping to improve efficiency, reduce costs, and assure a quality product. Prototyping is not merely a pass through stage, but one that your ECM uses as an essential step toward developing a reliable product for the end user. A turnkey facility with in-house engineers can handle the entire project and will use the prototyping stage to streamline the design and ensure a quality production run.

Rapid prototyping can give you the information you need in only a few days, and this quick turnaround will keep your project moving forward. There is no disadvantage to going through the prototyping stage to ensure you have the best product possible, and here at Levison Enterprises we highly recommend this process for every build.