Blog

How to Improve PCB Manufacturing Lead Times With an Electronic Manufacturer

March 27, 2023

As the saying goes, “time is money” and that’s certainly the case when talking about manufacturing lead times. Design engineers are being asked to design and bring to market more new products in less time. One way to combat shrinking design cycles is to outsource the fabrication and assembly of the printed circuit boards (PCBs) […]

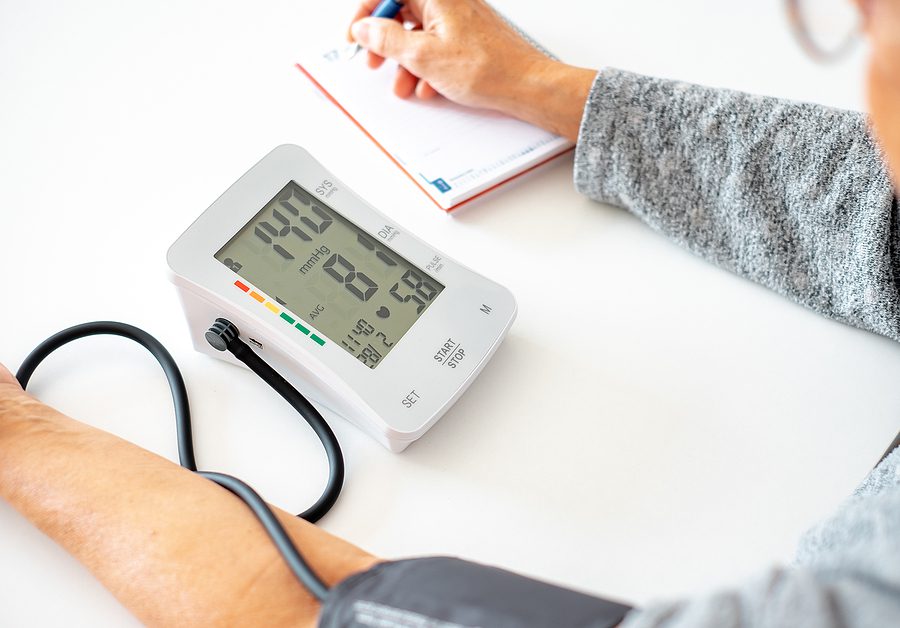

Your Medical Device Manufacturer can Help Keep Your Medical Device Within Proper Regulations

March 23, 2023

The medical device industry is highly regulated, and for good reason. Regulations exist to protect people by ensuring the safety and efficacy of the product. Obviously, medical device companies want to produce medical devices that are safe and effective, but they don’t always know how to handle the complexities of regulatory requirements. Even seasoned medical […]

Find the Right Medical Device Manufacturer for Your Project

March 21, 2023

Medical device companies understand the significance of selecting the right medical device manufacturer for their medical devices, as it helps them convert their ideas into working prototypes and finished products faster, saving both time and money.

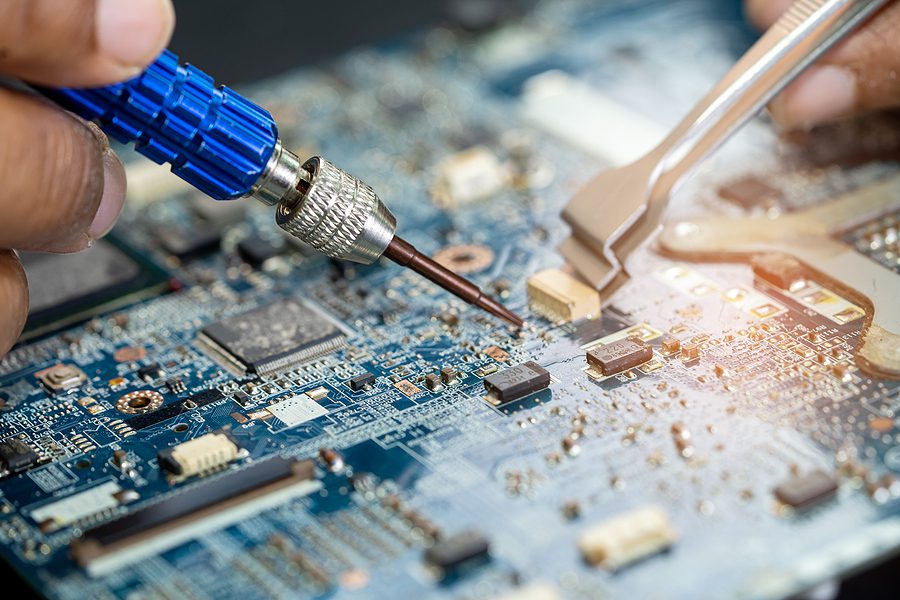

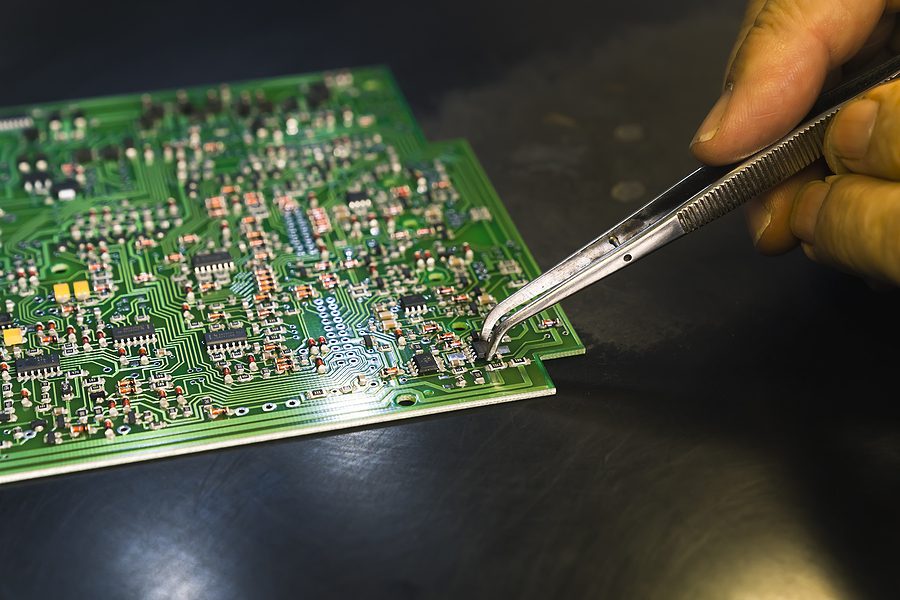

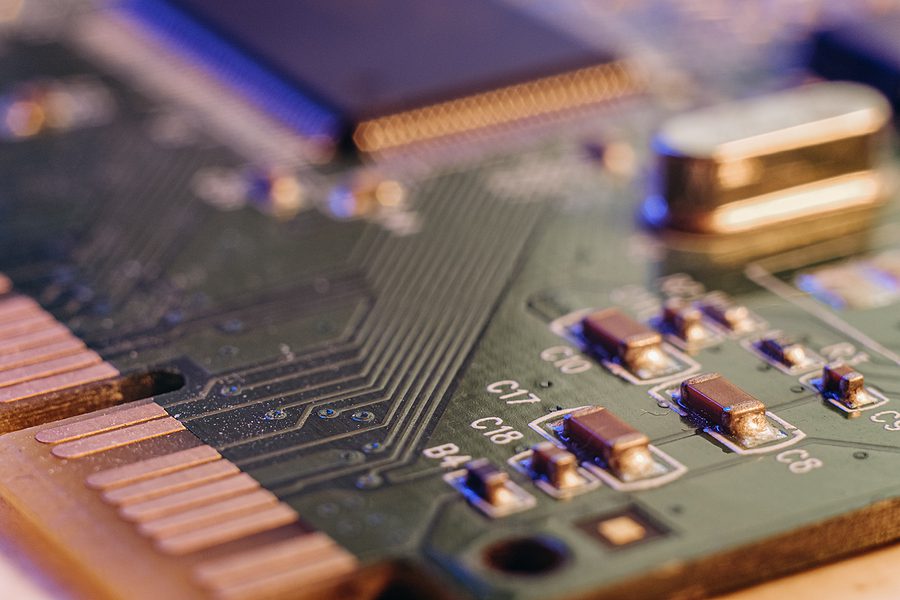

How to Keep Counterfeit Components Out of Your Electronic Assembly

March 17, 2023

One significant concern of electronic assembly manufacturer is the reliability of the components being used. Counterfeit electronic components have long been an issue for manufacturers, and the counterfeit industry continues to thrive by adapting new ways to mask part authenticity.

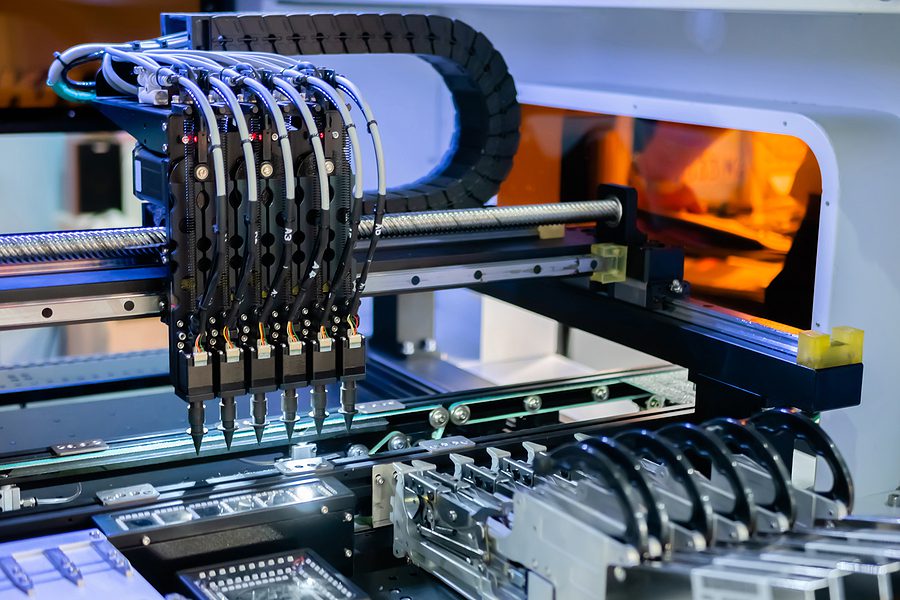

Move Your Project to a Turnkey Electronic Manufacturer

March 15, 2023

Product development is not an easy task. Getting your product from design to an electronic manufacturer takes a lot of time, money, patience, perseverance, knowledge, and expertise. Designers often clearly envision how they want a product to look and function. Still, if they lack a strong engineering background, they may face difficulties navigating the numerous, […]

Do Certifications Really Matter in Electronic Manufacturing?

March 13, 2023

If you want a quality experience and a quality end result from your ECM partnership, you should care about which certifications your ECM holds. They may not be required, but they do matter. There are many benefits to working with an ECM who holds certifications. You will know that you have a partner who chooses […]

Levison Enterprises Difference – Trusted Electronics Manufacturer

March 9, 2023

To truly excel at something requires you to immerse yourself in your work. Levison Enterprises has spent countless hours mastering electronic manufacturing design and production processes. Today’s consumers demand more than ever before and expect companies, even small and mid-sized, to turn products around quickly. A trusted ECM partner can help you achieve your goals […]

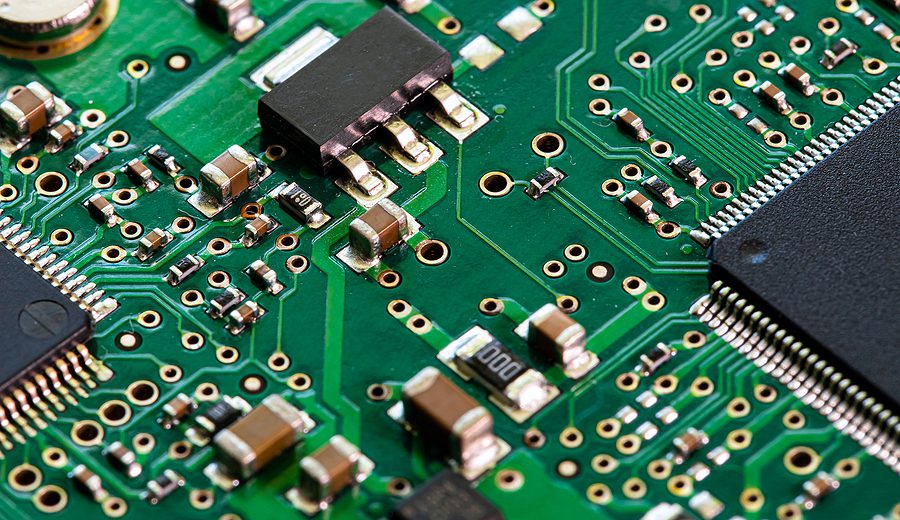

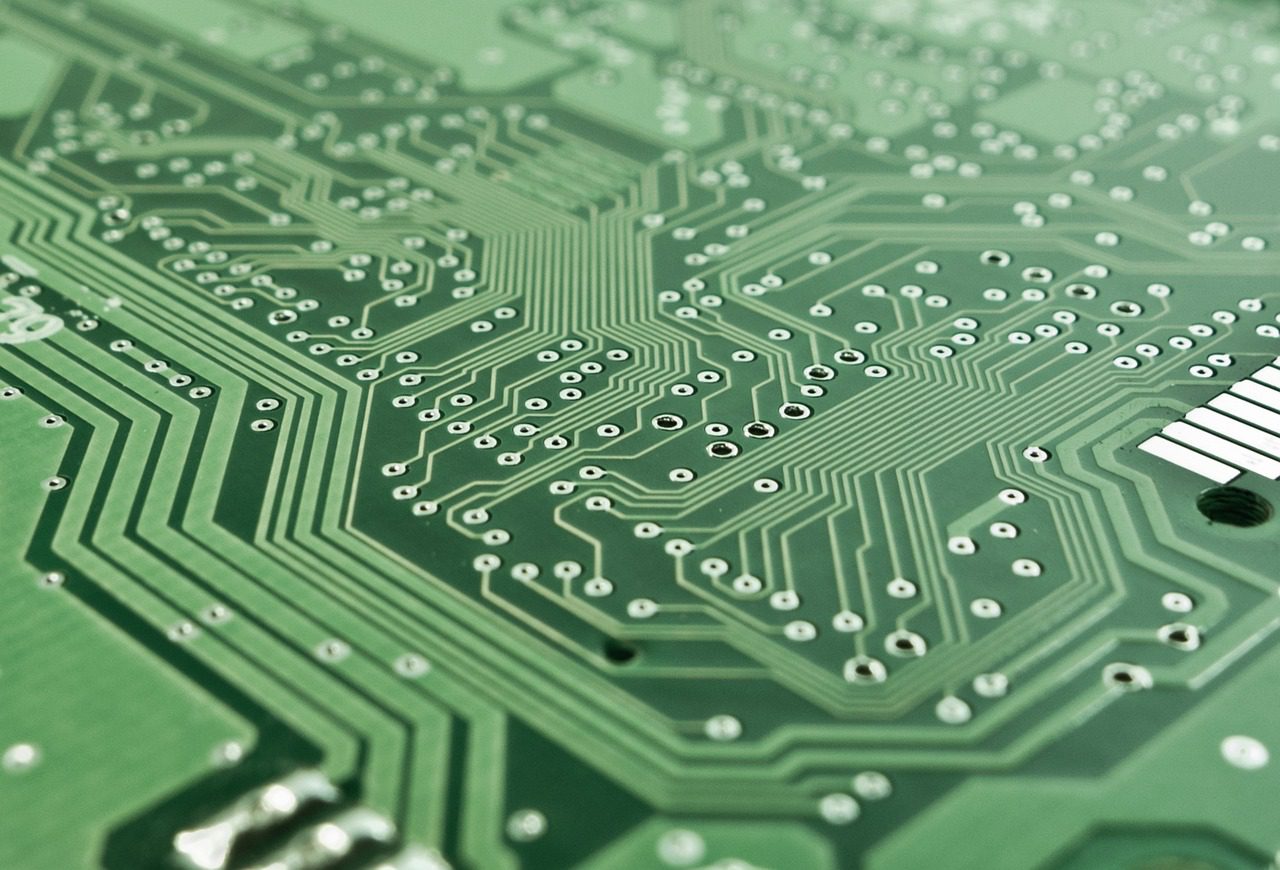

Electronic Manufacturers Create Efficiency in PCB Manufacturing and Assembly

March 7, 2023

Electronic manufacturers can seamlessly take your product from design to fulfillment without hitting novice bottlenecks. They know your industry, and have a broad knowledge of many industry standards and regulations.

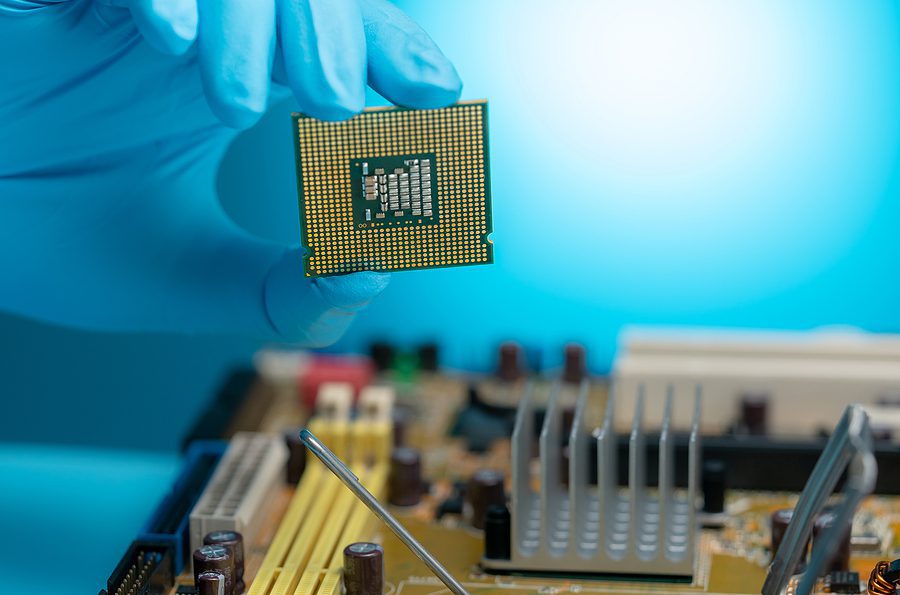

Benefits of an Experienced Turn-Key Electronic Manufacturer

March 3, 2023

You have a product idea that you’re ready to move forward with, and you need the right manufacturing partner to get your product to market. An experienced, domestic turn-key ECM can manufacture a reliable device quickly and efficiently. Mass producing a product with consistent quality, on-time delivery, and at the best cost is a delicate […]

Current Challenges in Supplying Electronic Manufacturing

March 1, 2023

The electronic manufacturing industry is a big business that keeps on growing. The competition is fierce, so survival requires flexibility. For an electronic device company to thrive, it must adapt to evolving technology and overcome current and emerging challenges. While the electronic manufacturing industry faces new challenges, there is also opportunity. To catch up with […]