Blog

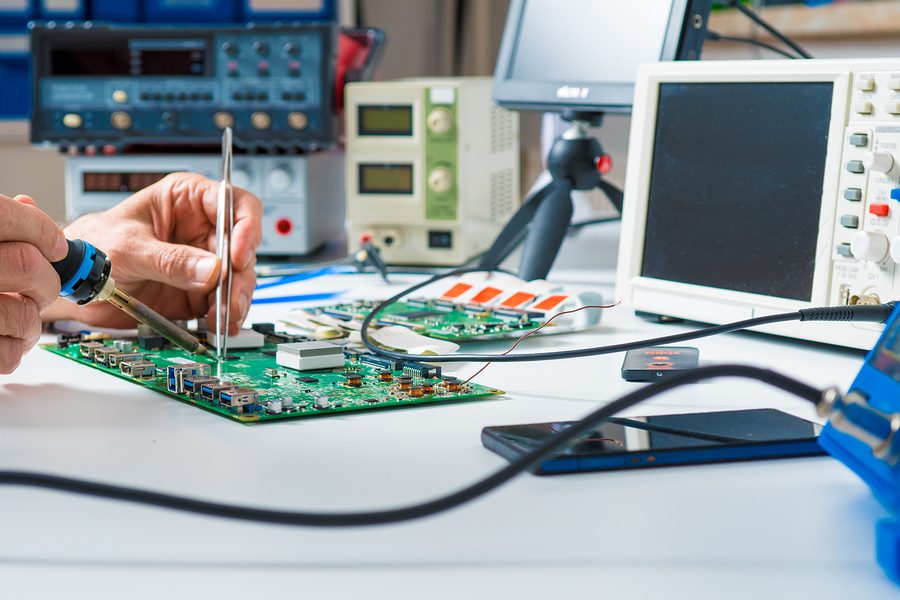

An Electronic Prototype Will Optimize Your Design

April 11, 2019

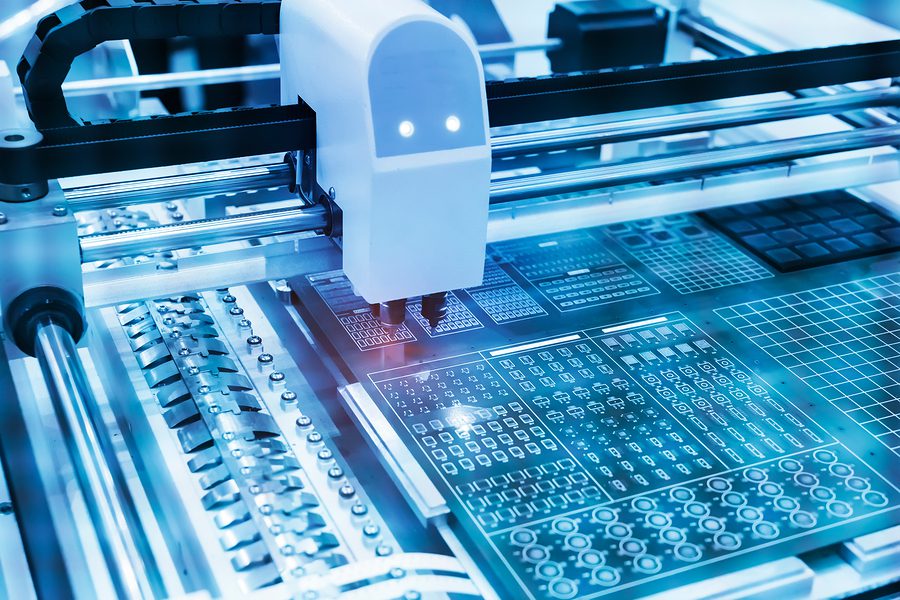

Prototyping is an important stage of product development. This useable representation of your design allows you to understand your product. The working model allows you to test various design features, verify design functionality and identify issues as early as possible within the development stage. Prototyping is often well worth the time, effort, and investment. If […]

7 Ways To Reduce Your Labor Costs During PCBA Electronic Manufacturing

April 8, 2019

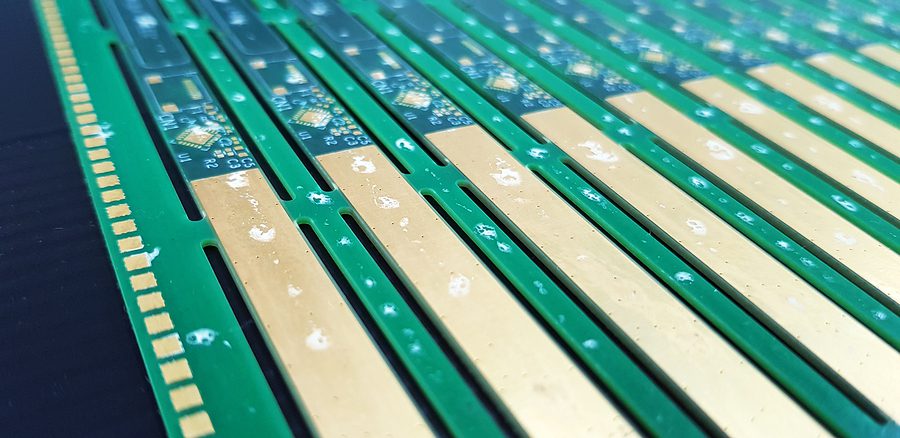

Labor cost can add up to the biggest part of your electronic manufacturing budget. So how do you cut costs without sacrificing the quality of your project? It is actually easier than it seems. It all starts with finding the right electronic contract manufacturer to partner with in order to create your printed circuit boards […]

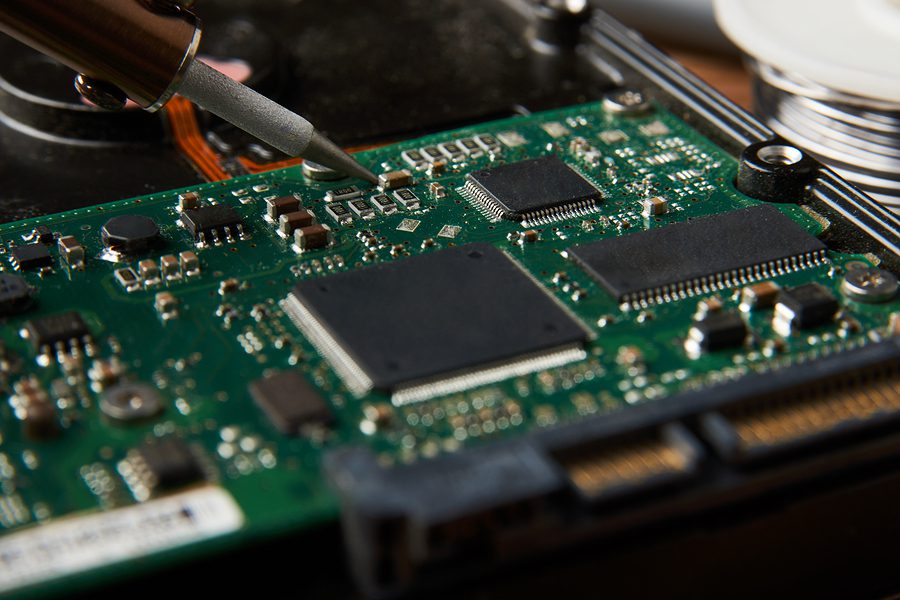

Lost In Translation: Electronic Design For Manufacturing

April 4, 2019

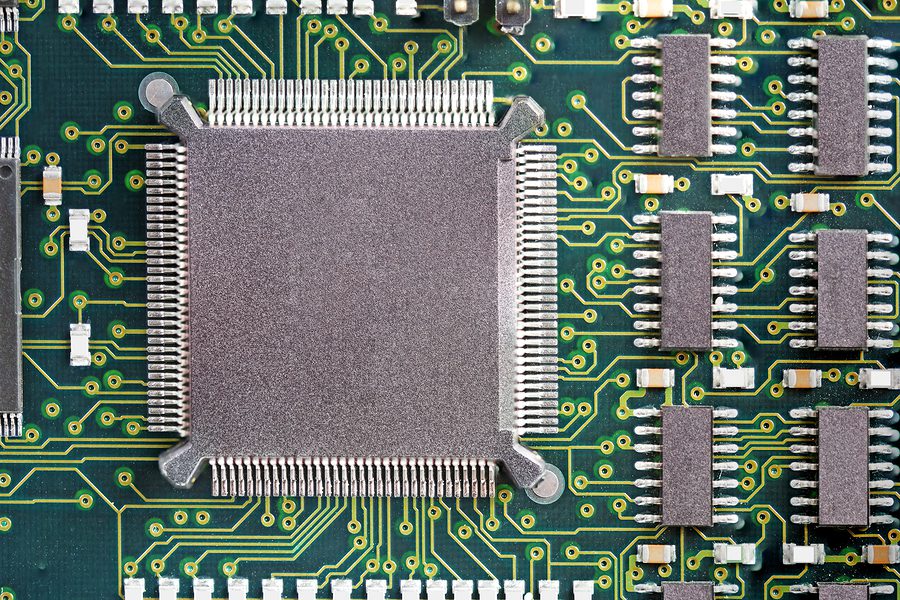

PCBs can get lost in translation between the designer and the manufacturer. What may look like an amazing design on paper may be difficult, costly, or even impossible to actually make. It’s important that your design for manufacturing analysis (DFM) is taken into consideration.

5 Tips to Optimize Your PCB Design for Manufacturability

April 2, 2019

You and your team work hard to bring a product to market. However, overlooking one tiny detail can mean the difference between a printed circuit board’s success and sending your PCB back to the drawing board. A Design for Manufacturability (DFM) analysis will take the worry out of the process. Performing DFM before production starts […]

Medical Device Manufacturing: How To Stay Competitive

March 28, 2019

Industry demand has kept most medical device manufacturers engaged in a constant battle to stay on top of the growing medical device manufacturing market. However, the industry is splitting.

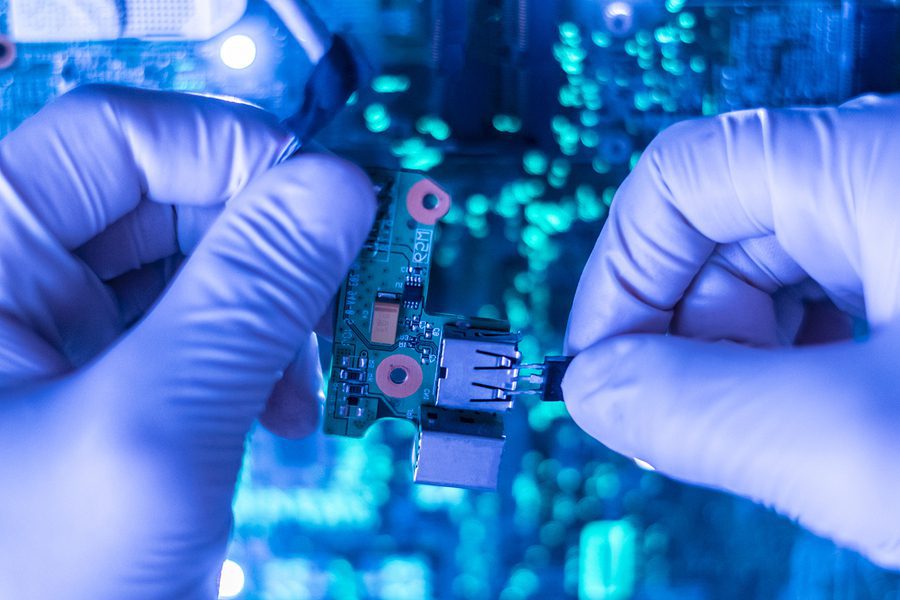

Reverse Engineering is Important To Your Legacy Electronic Assembly

March 20, 2019

Your legacy product has served you well. But is it time for an update? Bringing your legacy assembly up to speed with current and future technology doesn’t mean going back to the drawing board. When the designs are no longer available, reverse engineering might be the solution you’re looking for. With reverse engineering you can […]

Top Traits for Your Next Medical Device Manufacturer

March 14, 2019

The medtech industry is constantly changing. Technology evolves at a rapid pace and companies are working hard to keep up. The pressure is on to bring new and improved medical devices to market to revolutionize healthcare and to better (or save) lives. At the same time, companies need to improve efficiency and keep costs low. […]

3 Questions Before Outsourcing Your Medical Device Manufacturing

March 12, 2019

Rapid technology growth and evolution is revolutionizing the healthcare industry, and your company is leading the way to groundbreaking patient treatments. But you can’t do it alone. When considering outsourcing production of your medical device, there is a lot you need to consider when talking to medical device contract manufacturers.

What Is Medical Device Manufacturing?

March 7, 2019

As Baby Boomers age, and technology advances the ways in which consumers interact with medical care, medical device manufacturing is seeing new growth. Demand for new and improved medical devices continues to grow, meaning more demand for medical device manufacturers. When demand gets high and changes are happening quickly, contract manufacturing always has an important […]

Outsourcing Your Prototype to a Medical Device Manufacturer

March 4, 2019

Prototyping is a crucial part of designing a new medical device. Without it you will never know if your idea is viable. Of course, creating a prototype is easier said than done. Today most medical device companies prefer to hire another company to breathe life into their designs. Outsourcing your medical device prototype to a […]