Blog

Design Considerations for Military and Aerospace PCB Assembly

January 9, 2020

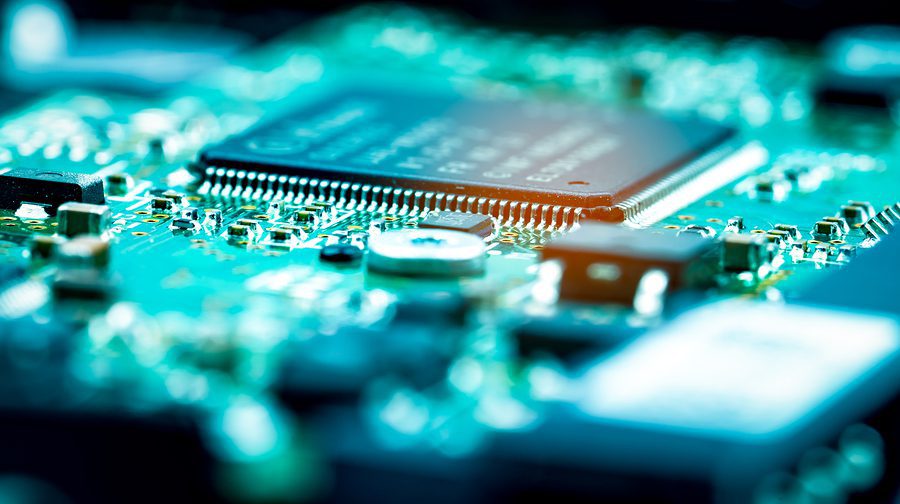

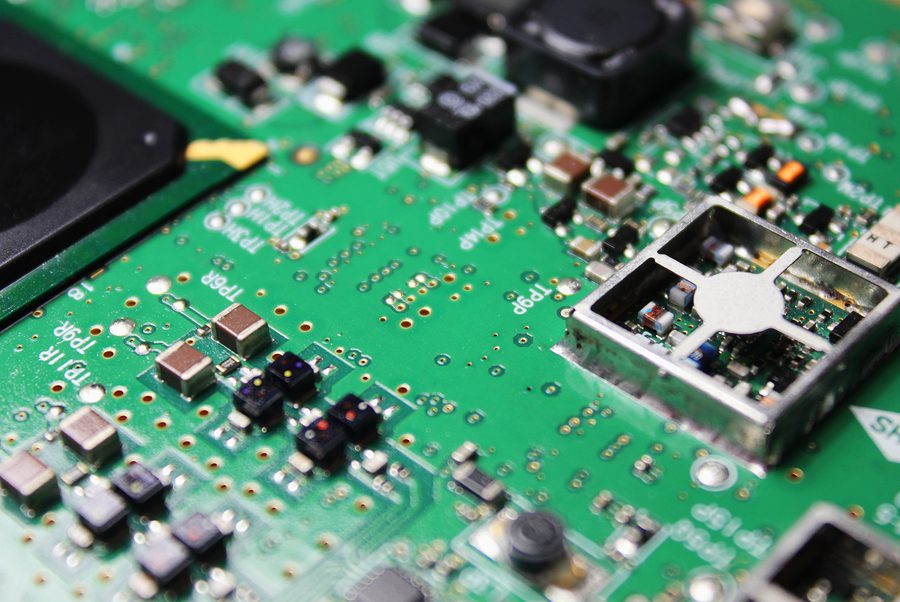

In today’s technologically advanced world, almost everything is made better, smaller, and more durable through the use of printed circuit boards, or PCBs. You’ll find them in televisions, computers, stereos, digital clocks, microwaves, and even cell phones.

Turnkey Aerospace Electronic Manufacturing Saves Time and Money

December 6, 2019

Sometimes you need a quick turnaround. Or, maybe you just want the convenience of sticking with one contractor for your aerospace electronic assembly. No matter the reason, turnkey electronic Assembly might be the right fit. Think of it as a one-stop-shop for circuit-board assembly. Your turnkey ECM takes care of the entire process, including obtaining […]

5 Factors That Influence Military PCB Design in Electronic Manufacturing

November 22, 2019

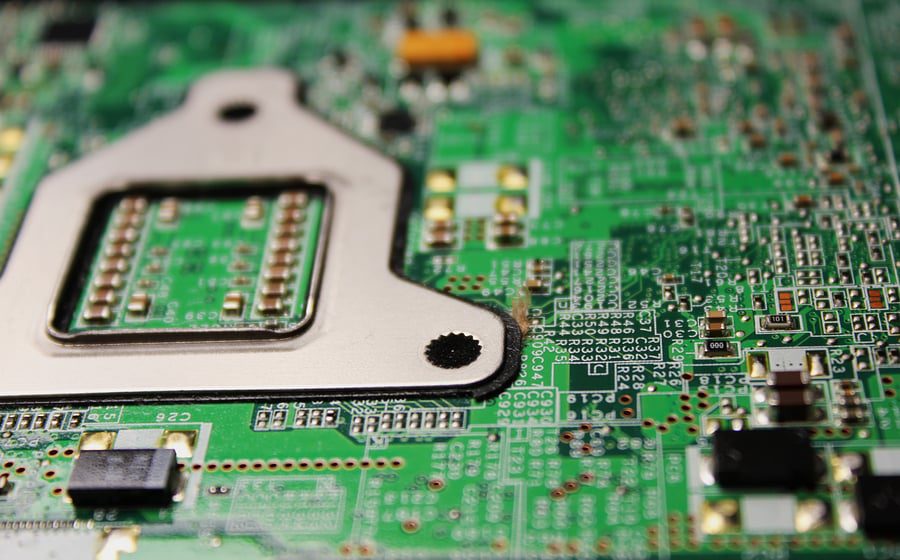

Aerospace and military-grade printed circuit boards must be as tough and reliable are those who use them in the field. There is no room for error and your electronic manufacturer is counted on to be mission ready. This makes PCB assembly and manufacturing for the military unique. Knowledge and understanding of what must be done […]

Does Your ECM Have the Technical Knowhow to Handle Your Project?

November 19, 2019

You’re looking for an ECM with the ability to take your project from idea to consumer’s hands. How do you know if an ECM will provide quality work on time? After all, your project’s success depends on it. An ECM with sub-par technical chops opens you up to defective and generally poor-quality products. You need […]

Is Your ECM Robust Enough to Build for the Military?

November 14, 2019

Tough, accurate, rugged, precise – these are all words that come to mind when talking about the military. But how do they translate to military-grade electronic assemblies? Only the most tenacious ECM with a mastery of electronic assembly can live up to unique military standards and deliver a product with proven precision. Military-grade electronic assemblies […]

What is Supply Chain Management and Why is it Important to Your Electronic Manufacturer?

November 11, 2019

Sometimes it’s hard to fully understand and appreciate what goes on behind the scenes to get a PCB off the drawing board and into a product. Supply chain management is one such element of PCB development that can be easily overlooked. It’s an essential part of manufacturing as a whole; one that directly impacts your […]

Benefits of a Domestic Medical Device Contract Manufacturing Partner

November 6, 2019

For years, medical device companies relied heavily on overseas manufacturers for production. There is a long-standing thought that you could save a lot of money by relying on foreign manufacturers for medical device contract manufacturing. However, that is not necessarily the case. With the US Food and Drug Administration (FDA) tightening regulatory standards and the […]

Avoid Delays in Your Next PCB Prototype

October 28, 2019

Mistakes happen. It’s a fact of life. But many are avoidable, especially when it comes to your PCB prototype. A simple oversight can delay your whole project. If you get behind while building a circuit board, the issue can quickly snowball, and your entire project timeline can become derailed. The problems can continue to compound. […]

Is Turnkey PCB Manufacturing Right for You?

October 15, 2019

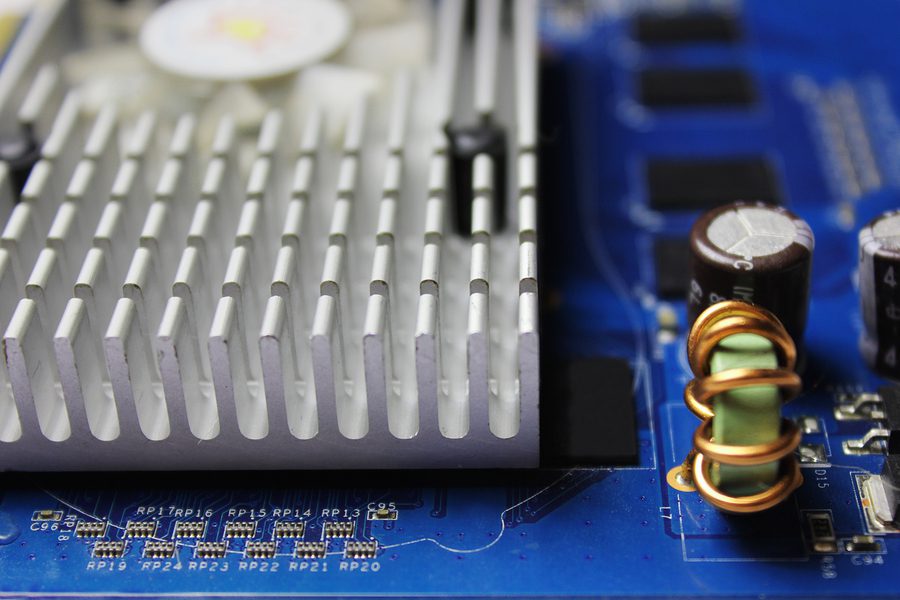

The PCB manufacturing process can be pretty involved. At times, upwards of 11 physical prototypes could be required before moving forward with production. This means the traditional approach to PCB board manufacturing can be pretty slow because it wasn’t designed for prototypes and small batch runs. It can also be expensive and prone to errors. […]

Are Electronic Assembly Certifications and Testing Really Necessary?

October 11, 2019

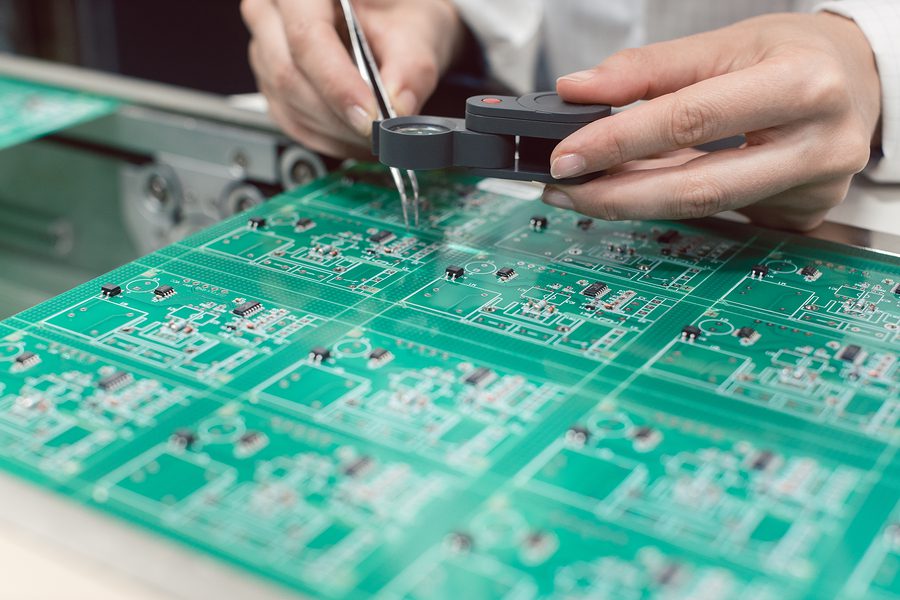

When you set out to create a product, you want it to be the best. You aim for quality, not just a passable product. So why settle for simply adequate when it comes to electronic assembly manufacturing? Certifications and testing are crucial to making sure your product delivers. Settling for less than that just won’t […]