Blog

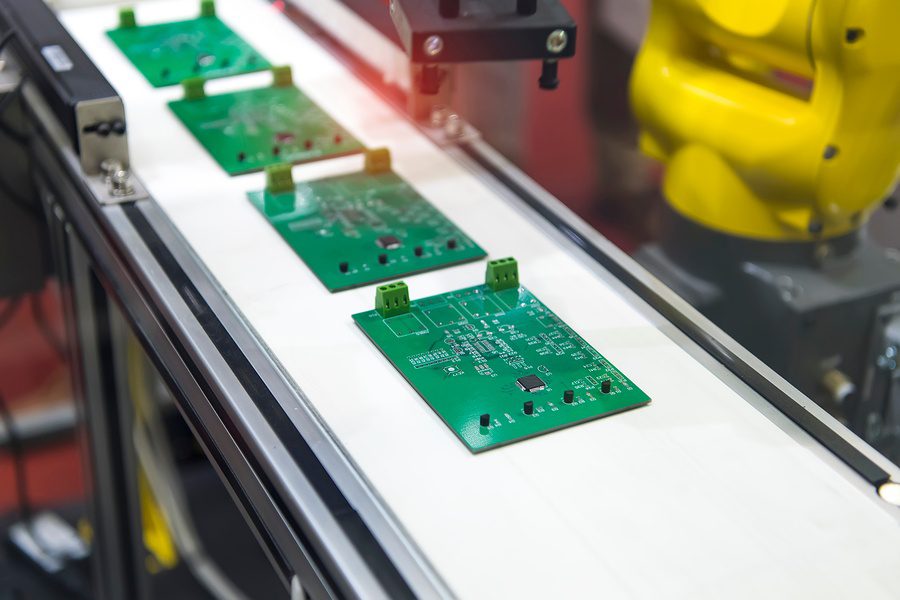

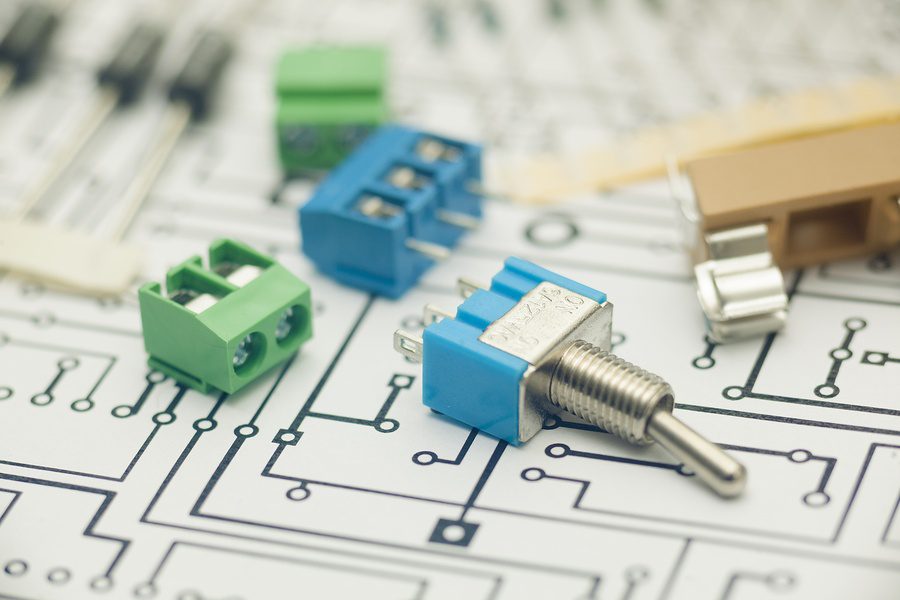

How to Select Components for PCBA Optimization

November 29, 2018

If you’re using an electronic contract manufacturer for your PCB assembly, then you will need to provide a thoroughly defined set of instructions for your board fabrication and PCB assembly, including the selection of components to be used based on the equipment capabilities of your electronic contract manufacturer. Your choice of components will have an […]

Why Use a Domestic PCB Assembly Manufacturer

November 5, 2018

When it comes to selecting your PCB assembly manufacturer, what do you look for? Obviously, you’ll need a partner that can do the job, but what else is important to you and your product?

4 Ways In House Engineering Support Helps Your Electronic Assembly

November 2, 2018

When you’re choosing an electronics contract manufacturer (ECM), there are lots of options you need to weigh. Whether you’ve already got a concept for your project, or need design help to bring your idea into reality, an important factor to add to your list of considerations is whether or not the ECM has engineering support. […]

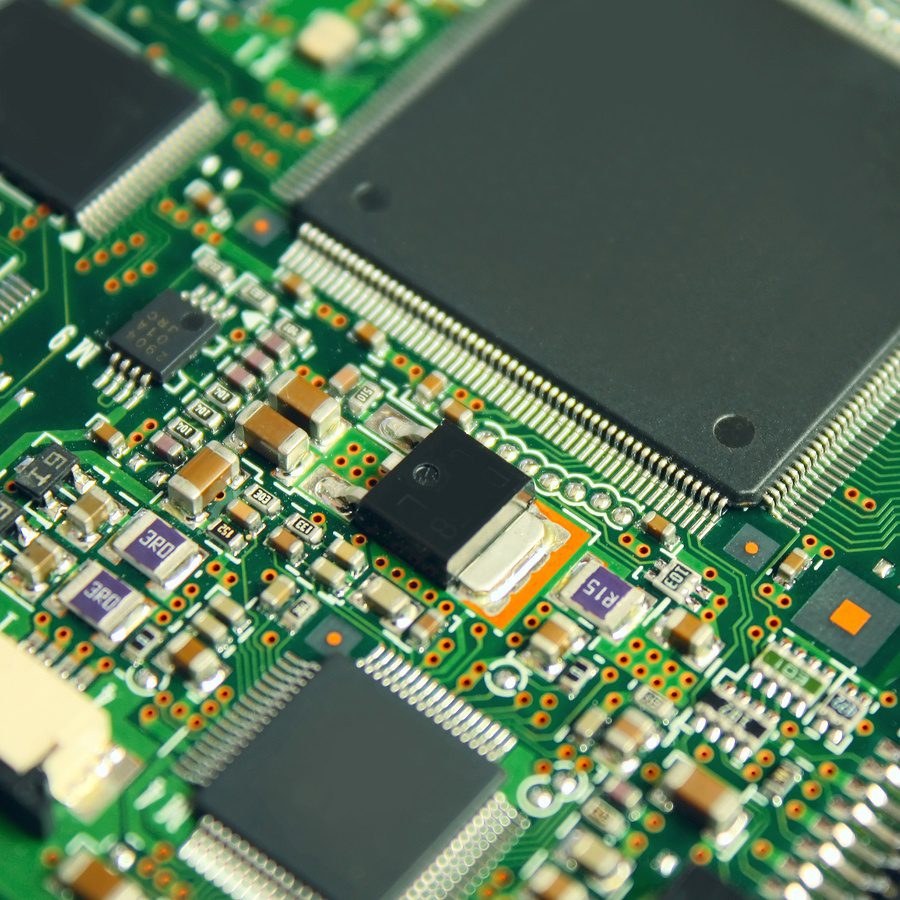

Advantages and Disadvantages of Multi-Layer PCB’s in Electronic Manufacturing

October 30, 2018

Printed circuit boards (PCBs) are right in the center of the rapidly growing and changing world of electronics and electronic manufacturing. The push for faster, lighter, and more robust electronics products has given birth to multiple ways to use PCBs in order to meet those demands. One way that printed circuit boards have been shown […]

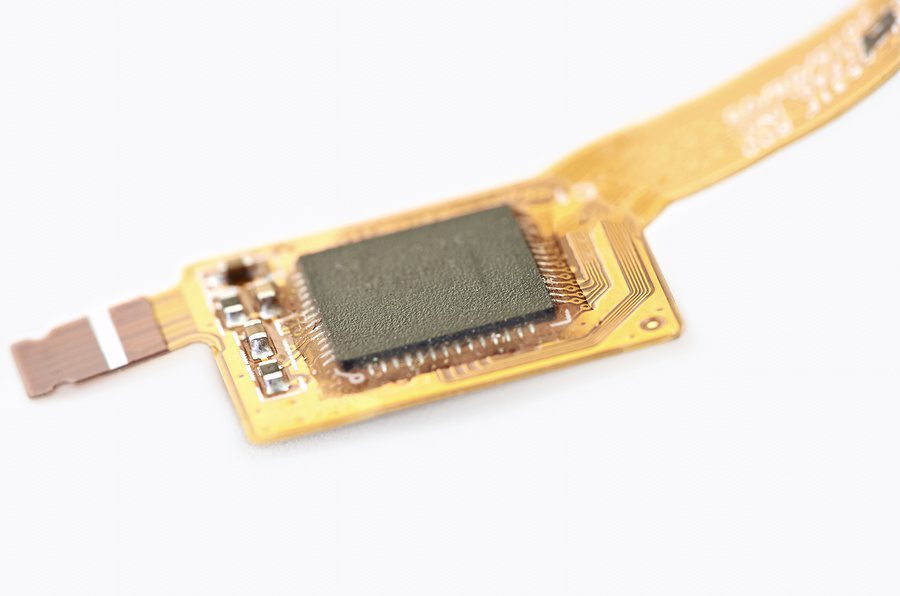

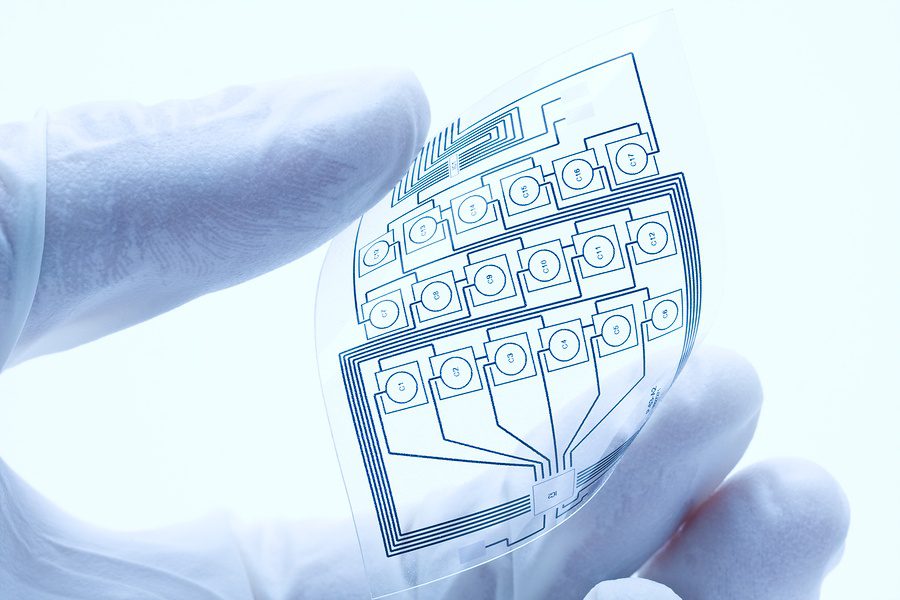

Using A Flexible Circuit In Your Next Electronic Assembly

October 25, 2018

Flexible electronics. A generation ago, we thought that a flexible electronic meant you could hoist your boombox up on your shoulder and carry it around. Although this idea of flexibility produced the iconic look of the 1980s, it comes nowhere near what modern flexible electronics can do.

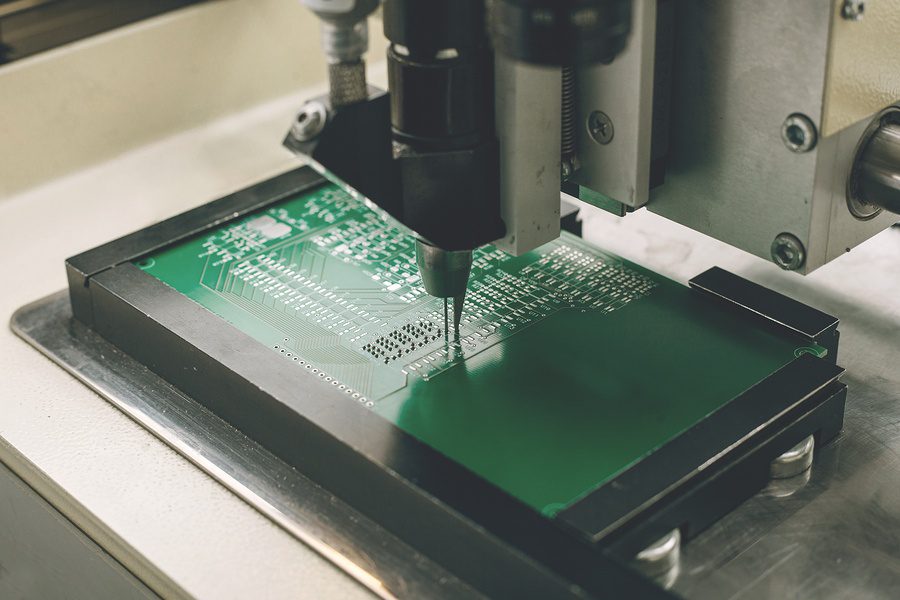

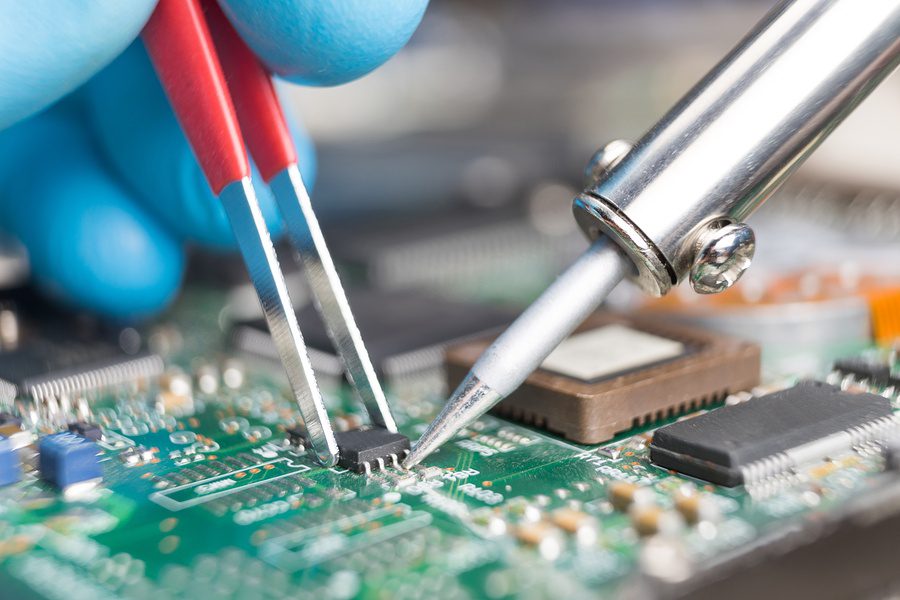

Lead Free vs. Leaded Solder in Electronic Manufacturing

September 13, 2018

Prior to 2006, most of the metallic components in electronic devices were created using tin or lead solder. These materials were reliable, easy to observe and understand and readily available. Assemblies were designed specifically for use with tin/lead solder, including the temperatures required to work with these materials during electronic manufacturing.

Benefits of Surface Mount Technology

August 29, 2018

If you have held a TV remote control in your hand, punched a button on a microwave or adjusted a digital thermostat, you have interacted with surface mount technology, or SMT. Since the 1980s, nearly all mass-produced electronics are now manufactured using SMT.

Flexible Printed Circuit Boards and Rigid Circuit Boards

August 23, 2018

When you hear the term “PCB,” what do you think of? Most people probably imagine a rigid PCB (printed circuit board) with traditional copper pads and wiring harnesses. More and more, however, PCB can also refer to a flexible PCB, also known as a flexible printed circuit board. With the growth in small electronics, the […]

Principles and Considerations for Design For Electronic Manufacturing

August 16, 2018

When you’re manufacturing a product, there are usually three considerations you need to meet by the time it’s finished. The product needs to meet your desired level of quality, it needs to meet your performance standards, and it needs to be able to be priced competitively. An experienced electronic manufacturer can help you achieve these […]

What is the difference between SMT and SMD For An Electronic Manufacturer?

August 14, 2018

SMT and SMD. These two little acronyms get mixed up a lot in the electronics manufacturing service world. For electronic manufacturers on paper, they only vary by a single letter, but in practice, there’s a lot more separating SMTs and SMDs. Chiefly, one is a process and the other is a device.