Blog

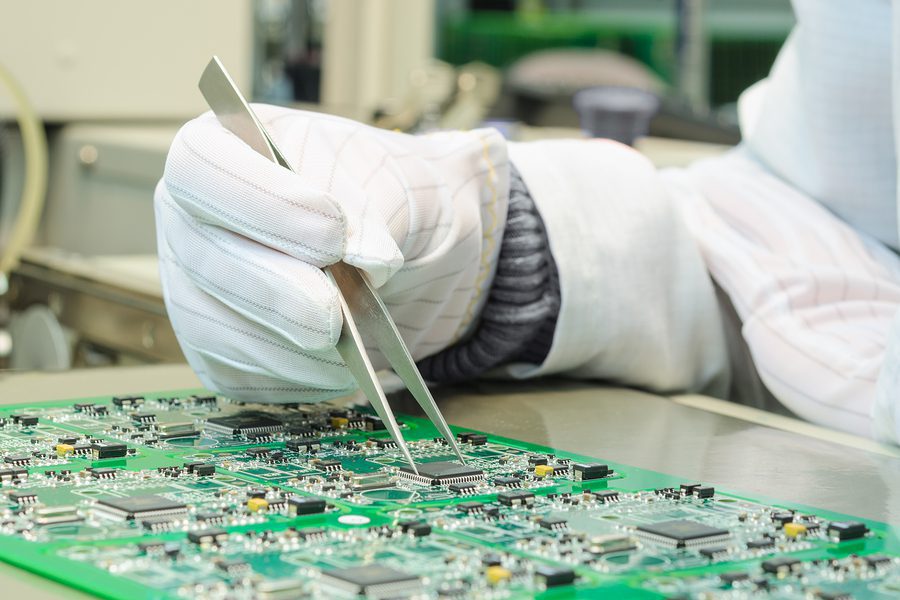

Avoid Delays in Your Next PCB Prototype

October 28, 2019

Mistakes happen. It’s a fact of life. But many are avoidable, especially when it comes to your PCB prototype. A simple oversight can delay your whole project. If you get behind while building a circuit board, the issue can quickly snowball, and your entire project timeline can become derailed. The problems can continue to compound. […]

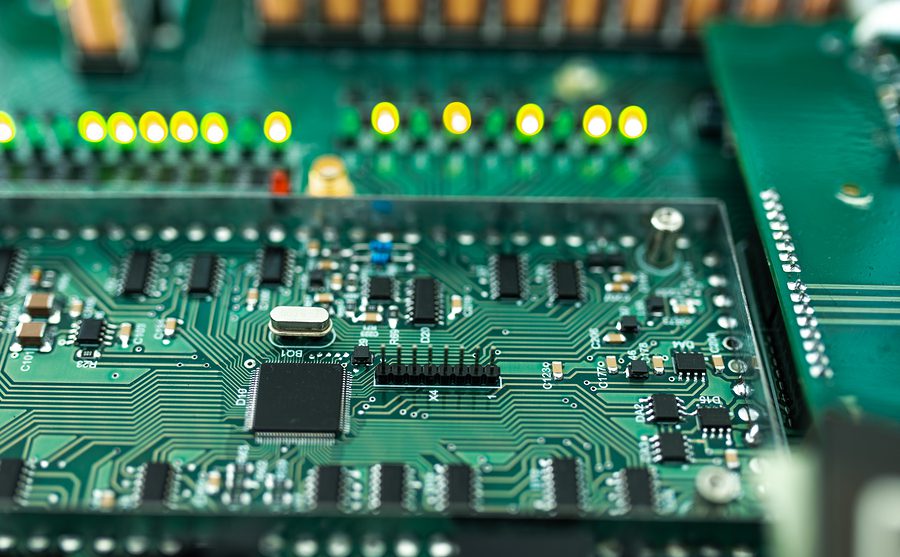

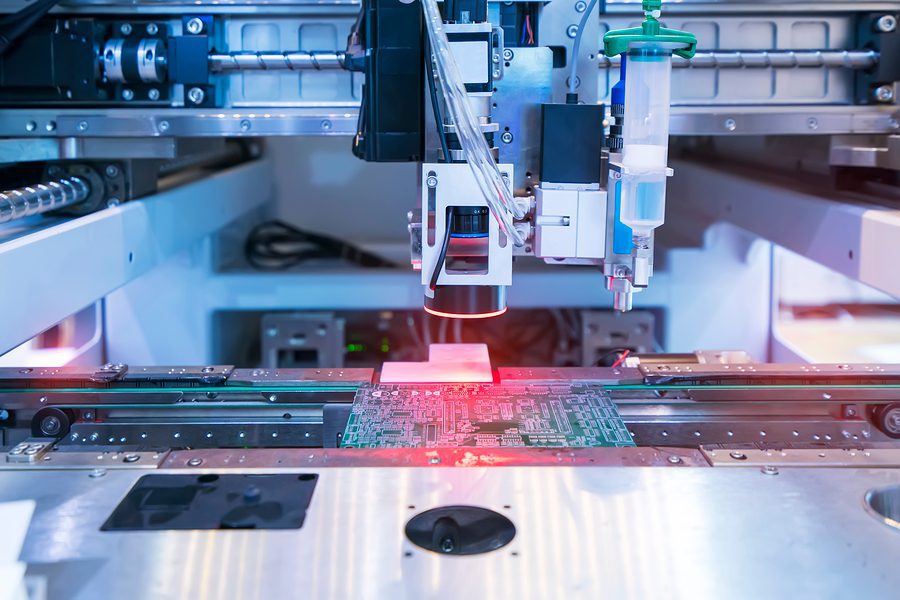

How Design Impacts PCB Manufacturing Process

October 24, 2019

PCB design is a complex process. Careful considerations, down to the tiniest detail, must be made. All of your design choices will affect one or more stages of the PCB manufacturing process. This includes everything from shape and size to what type of drill hole technology you use. Failing to pay attention to how your […]

Is Turnkey PCB Manufacturing Right for You?

October 15, 2019

The PCB manufacturing process can be pretty involved. At times, upwards of 11 physical prototypes could be required before moving forward with production. This means the traditional approach to PCB board manufacturing can be pretty slow because it wasn’t designed for prototypes and small batch runs. It can also be expensive and prone to errors. […]

Are Electronic Assembly Certifications and Testing Really Necessary?

October 11, 2019

When you set out to create a product, you want it to be the best. You aim for quality, not just a passable product. So why settle for simply adequate when it comes to electronic assembly manufacturing? Certifications and testing are crucial to making sure your product delivers. Settling for less than that just won’t […]

An Electronics Manufacturing Service Can Save You Time and Money

September 23, 2019

Outsourcing has become the way of life for original equipment manufacturers. A third-party electronics manufacturing services partner (EMS) handles assembly of circuit boards and other electronic devices leaving you to focus on the big picture of your project. A manufacturing partner can streamline your production process and dramatically cut costs. Here are some examples of […]

Electronic Manufacturing Services for the Food Industry

September 19, 2019

Quality and safety are of the utmost importance to the food manufacturing industry. Failure of process standards for contamination control could result in sickness for hundreds or thousands of people or even lead to someone’s death. Needless to say, there are strict standards in place. And you should expect the same when it comes to […]

Benefits of an Electronic Manufacturer Partnership

September 4, 2019

Companies are always looking to get an edge on the competition and improve their bottom line. As technology evolves, you may not have the proper resources you need to competitively get a new product from concept to market. You may need to consider turning to an outside electronic manufacturer.

Use an Electronic Manufacturer To Take Your Product To Next Level

August 26, 2019

You’re really good at what you do, you’ve got a sweet product that you are so close to taking to the next level, but you’re stuck. Stuck in design, stuck in function, STUCK. You need some new ideas to move your product forward. Consider using an electronic manufacturer to breathe new life into your design.

Electronics Troubleshooting Hacks With On-Site Engineers

August 22, 2019

In the world of Murphy’s Law, if it can go wrong, it will. If your mechanical assembly needs an electronic assembly inside, you really want an electronic contract manufacturer with engineering on staff to help with your electronics troubleshooting. On-site engineering means someone is ready to tackle your PCB repair challenge at a moment’s notice. […]

5 Advantages To Using SMT in Your Electronic Manufacturing Project

July 31, 2019

How Surface-Mount Technology Transforms PCB Design