Blog

Ultimate Capabilities Checklist for Outsourcing to a Trusted Electronic Contract Manufacturing Shop

October 26, 2022

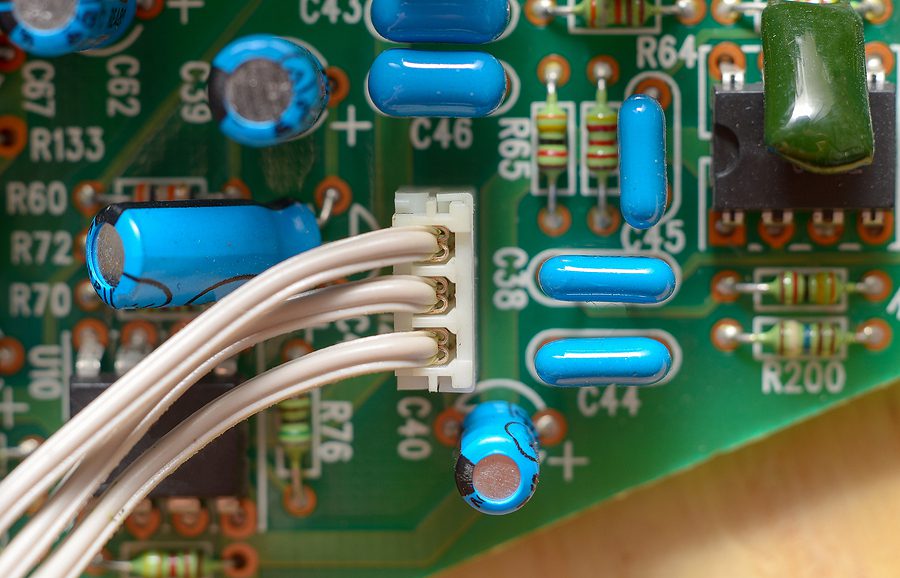

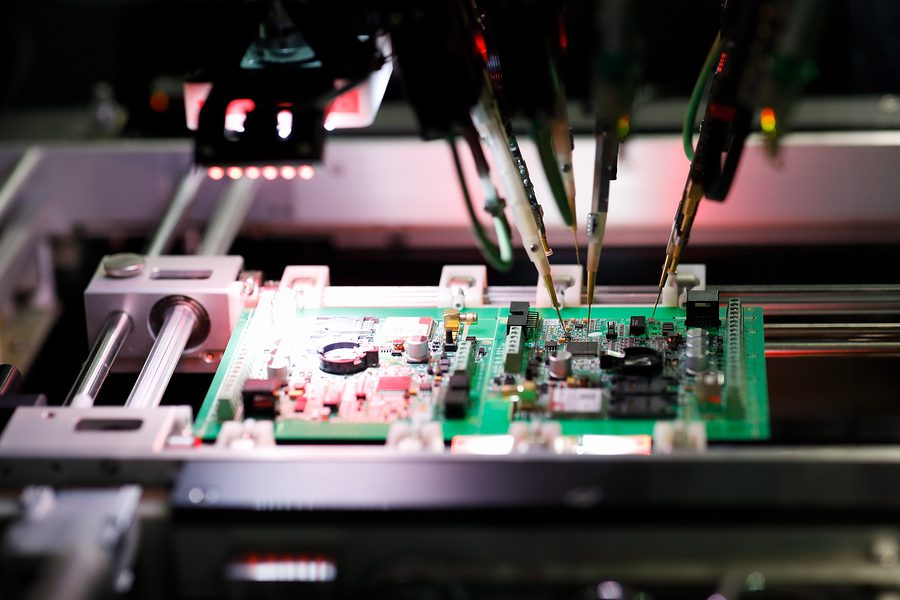

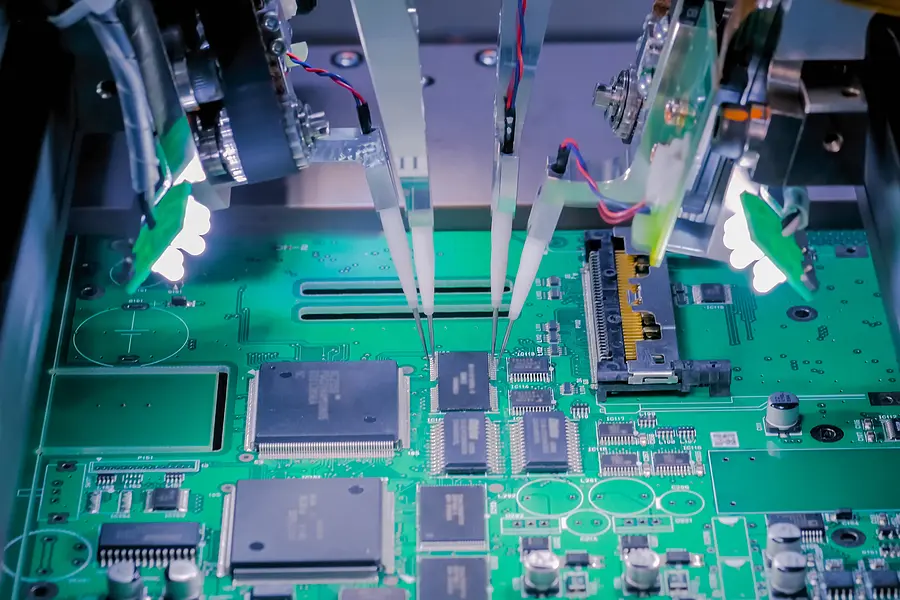

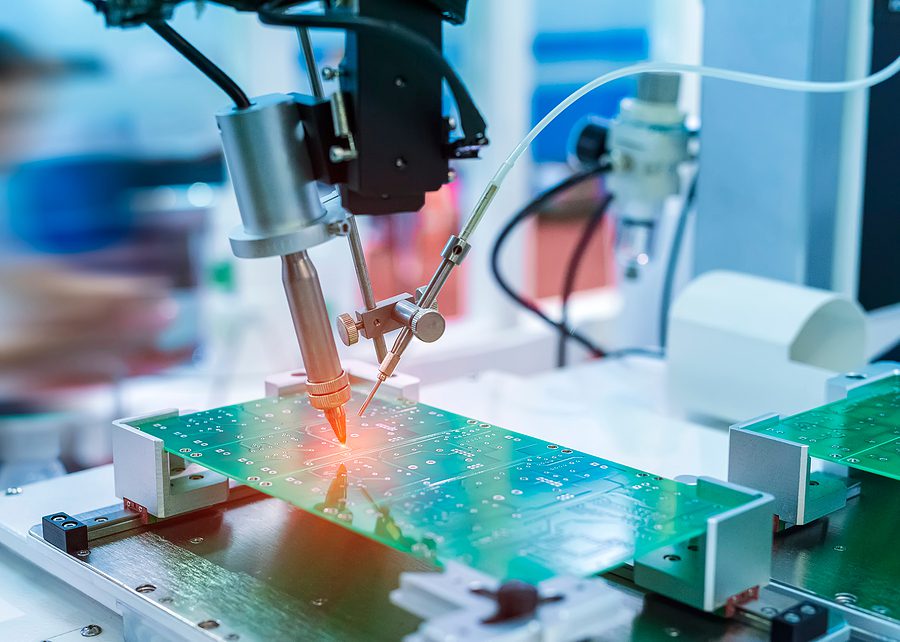

When you are developing a product with a PCB component, outsourcing to a trusted ECM shop is one of the best decisions your company can make. Maintaining a full engineering team for design as well as a turnkey manufacturing line simply isn’t practical for most companies, so an ECM partner is the perfect solution to […]

ITAR Compliance in PCB Manufacturing

August 4, 2022

When looking for an ECM for PCB manufacturing, it may be important to look for an ECM who is ITAR compliant. Although not every industry requires ITAR compliance, a company that follows the ITAR guidelines is a company that can be trusted to always be in compliance with any regulatory needs, and that can be […]

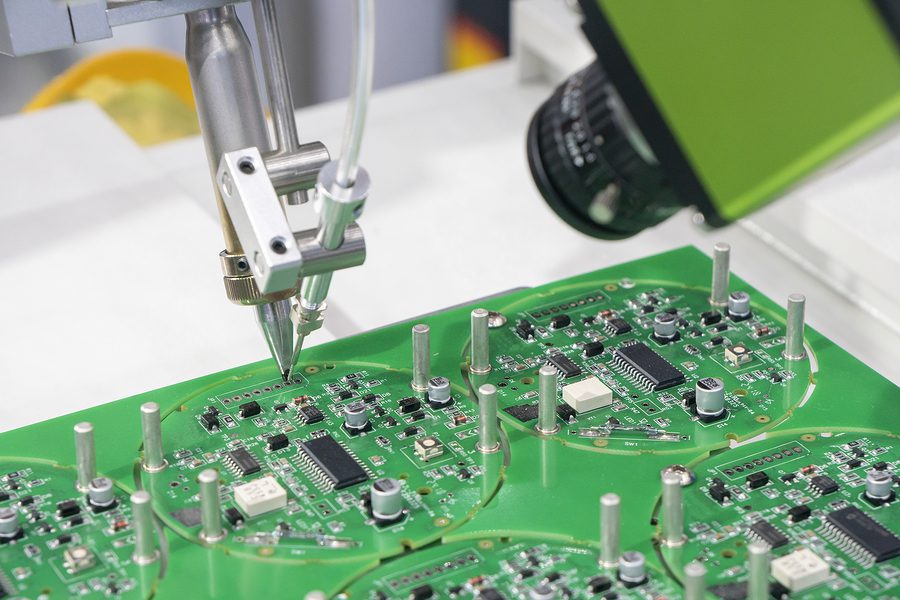

Taking Hold of the Rising Demand for Quality Medical Device Manufacturing

June 29, 2021

The demand for quality medical device manufacturing is rising steadily and this trend is expected to continue. With the increasing demand for devices, developers are looking for electronic medical device manufacturers to partner with for production. A manufacturing partner will need experience and certain capabilities to meet this demand at the level of quality and […]

Finding The Best Electronic Manufacturer for Your PCB Design

April 27, 2021

Designing a printed circuit board (PCB) requires a high level of expertise. You may not have the resources and skills readily available to create the powerful PCB you need for your next big project. Sometimes you need help with printed circuit board designing. Partnering with an electronic manufacturer is beneficial for many reasons. More and […]

What is Your Electronic Manufacturer’s Obsolescence Management Plan?

January 26, 2021

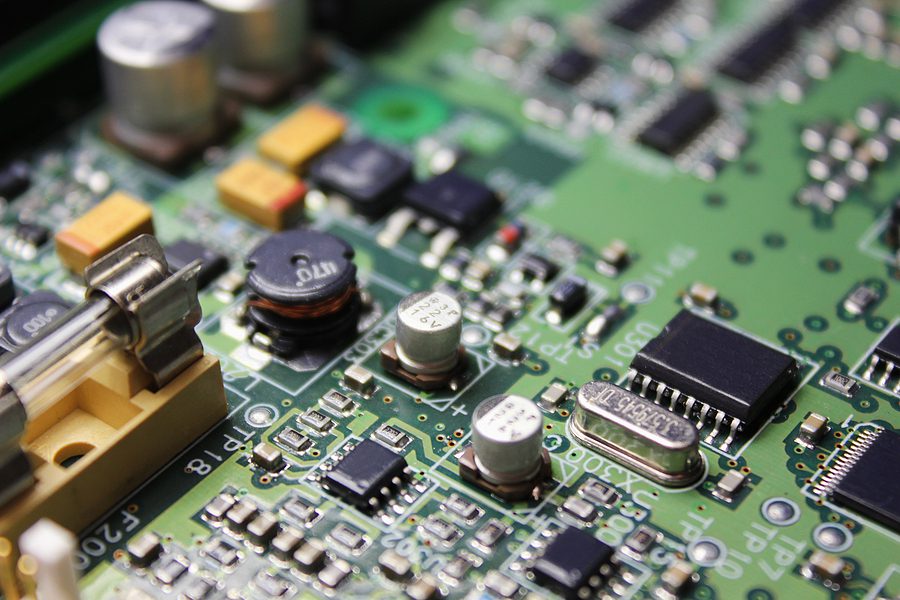

When a PCB ages, some components on the board may no longer be available for replacement if needed. Obsolescence is when your electronic manufacturer or PCB has components that are past the point of repair or replacement, which can render an entire system dysfunctional. An obsolescence management plan will ensure that your product line is […]

Is Your Electronic Manufacturing Partner Ready For Your Project?

October 2, 2020

You have a lot of choices when it comes to partnering with an electronic contract manufacturer. So, how do you know the electronic contract manufacturer (ECM) you choose will be ready for the challenge of your project? The best way to avoid partnering with an ECM who isn’t capable of successfully managing and manufacturing your […]

Partnering with a Domestic ECM Can Save You Money

September 23, 2020

There seems to be a common thought that partnering with an overseas electronic contract manufacturer can save you money. That misconception is just that…and far from the truth. In fact, partnering with a domestic ECM can save you much more money in the long run. There is a long list of reasons, all of which […]

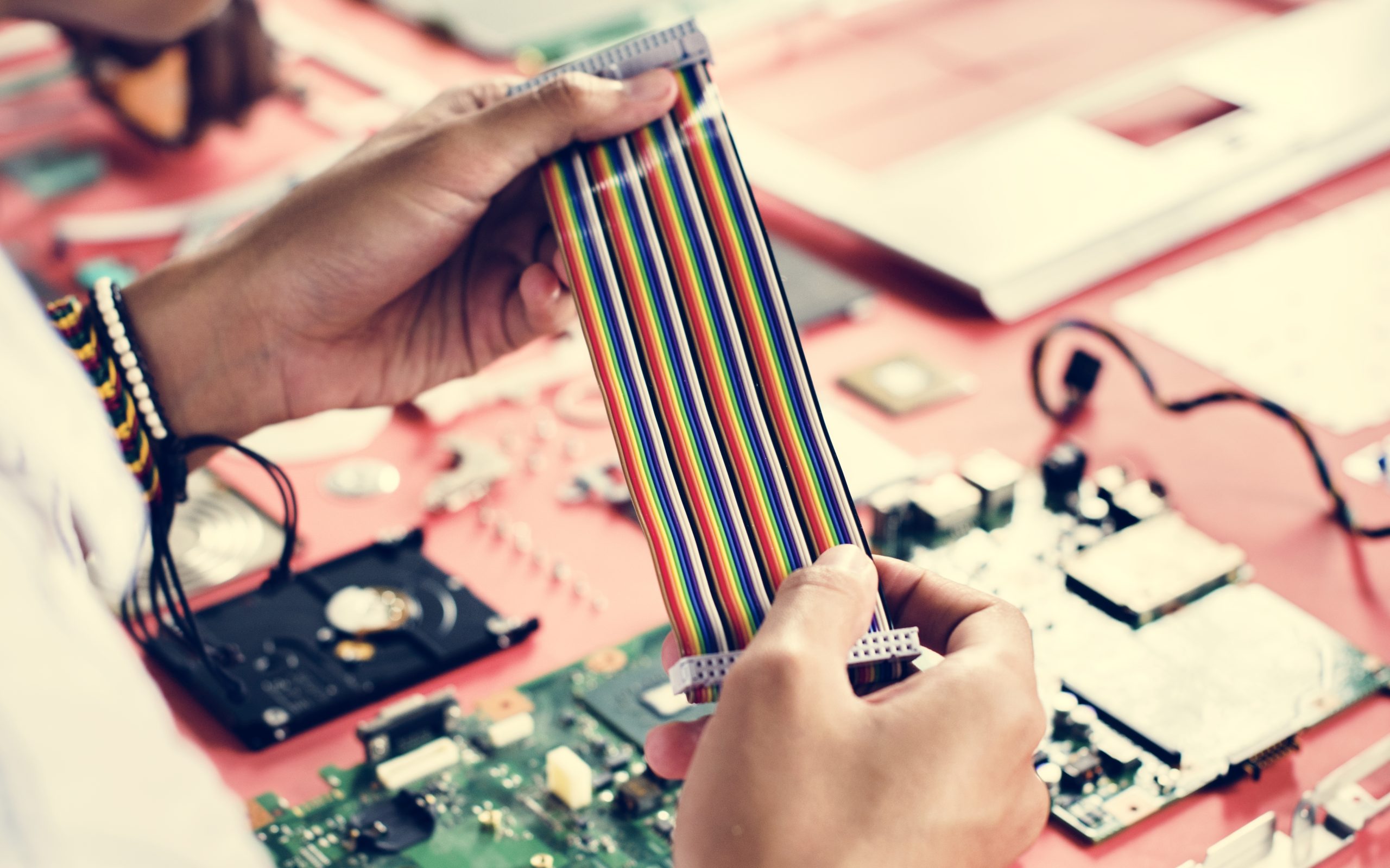

Flex Circuit vs. Rigid Circuit: Which is Right for Your Project?

May 20, 2020

Gone are the days when a printed circuit board was only available as a rigid board that allowed for minimal design versatility. The introduction of flexible PCBs into electronic manufacturing has opened up limitless design possibilities. While using the cutting edge technology of a flex circuit seems extremely appealing, sometimes utilizing a traditional rigid board […]

Obsolete Parts is the Great Vulnerability in an Electronic Manufacturing Supply Chain

May 13, 2020

Counterfeits are everywhere. The electronic industry is particularly vulnerable. Electronic technology is rapidly changing, and sometimes it is hard for electronic manufacturers to keep up. The need to regularly source parts or complete a rapid redesign due to parts obsolescence only increases the risk of fakes making their way into your product. It may seem […]

Parts Obsolescence Continues to Cause Headaches in Electronic Manufacturing

May 6, 2020

The electronic manufacturing industry has been battling the problem of parts obsolescence for decades. In an environment where the lifecycle of a component is shorter than the lifecycle of a product, part shortages lead to other headaches. Counterfeit electronic components entering the supply chain is one of the biggest issues resulting from hard-to-source parts. Manufacturers […]