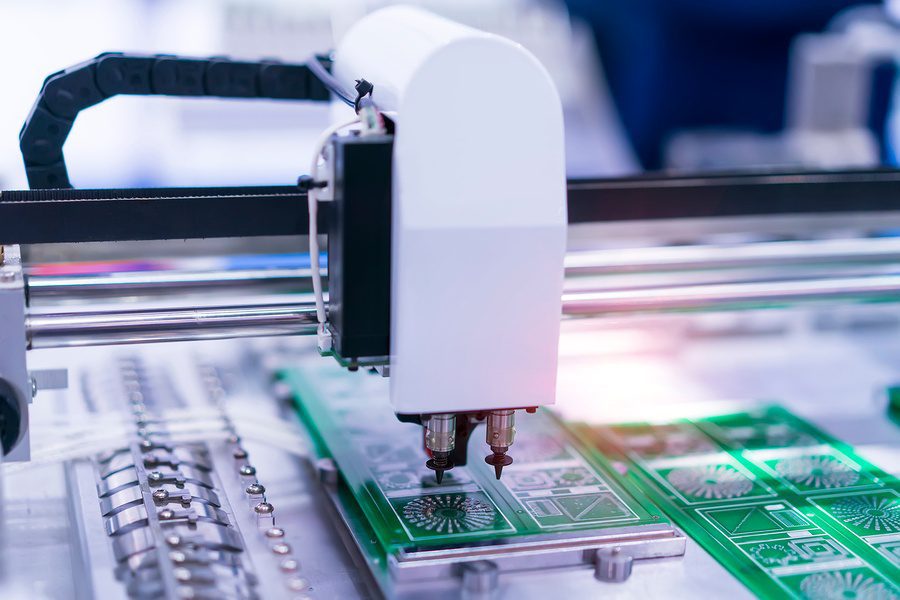

Why Outsource Your PCB Prototype Assembly

As electronics evolve and technology becomes more complicated, companies no longer have the facilities or capabilities to assemble PCBs. This is especially true when it comes to prototyping. Turning to an electronic manufacturer to help with the prototyping process just makes sense. Electronic assembly manufacturers are experts in their field. There are a number of advantages to outsourcing your prototype to an electronic manufacturer.

Save Money

All businesses want to save money, and you can save a lot by outsourcing your PCB prototype assembly. When hiring an outside assembler, you eliminate the cost of machinery, staff and space required to create a prototype circuit board. A PCB manufacturer will already have quality equipment and experienced staff on hand. By outsourcing your PCB prototype assembly, you will spend far less than the up front capital you would need to do it on your own.

Better Rates on Parts and Supplies

Due to the low volume of production, prototyping can be expensive. This is especially true when it comes to obtaining parts. By outsourcing your prototyping, you can take advantage of your partner’s proven supply chain to get low prices on specific parts for your assembly. This will also help you avoid low-cost counterfeit parts which have become a major concern in electronic manufacturing. Fake parts can cause headaches down the road. You can select a prototype manufacturer that guarantees authentic parts to protect your project.

Design for Manufacturability

Design for Manufacturability (DFM) is a critical stage in your product development process. Your assembler will guide you through the DFM stage of development making suggestions on parts and design alternatives to save time and money. The work your ECM does for you at this stage will also reduce the time for design and development and eliminate unnecessary rework, which provides additional cost savings. Having an outside source design your PCB prototype should prove to be invaluable to your business.

Engineering Support

Wouldn’t it be great to streamline the steps between prototype and production? Outsourcing your PCB prototyping can do that. Your ECM’s engineers will be part of the prototype process. They will be able to identify areas that may need improving and offer suggestions on how to make that happen. Consider your prototype partner as an extension of your existing team. Experienced engineers can create drafts of your design that can cut lead times and streamline your production process with prototypes that you can make changes to before committing to a final production timeline and assembly.

Email SalesTesting In-House

Your PCB assembly team will put your PCB prototype through its paces to ensure it’s ready before you go into full production. A quality electronic manufacturing partner will come up with multiple testing cycles, experiments, and new solutions for your product that you might not have thought of or used before. This testing phase is so important. You want a PCB prototype manufacturer that will stand by their work. The testing they do early on will ultimately save you time and money by catching and fixing issues before production begins.

Quality Certifications

We always maintain the proper quality certifications and work hard to exceed customer expectations. You want to outsource your PCB prototype build to a company that delivers the highest quality services and end results each and every time. Quality certification takes a lot of effort and consistently maintaining quality certifications says your prototype partner takes quality seriously.

Levison Enterprises is AS9100 certified, ISO 9001 certified, IPC and J Standard certified, U.S. SBA certified, as well as ITAR registered. We are ready, willing, and able to take on your prototype project. Contact us today to find out how Levison Enterprises can turn your drawings and plans into a prototype that is ready for full production.