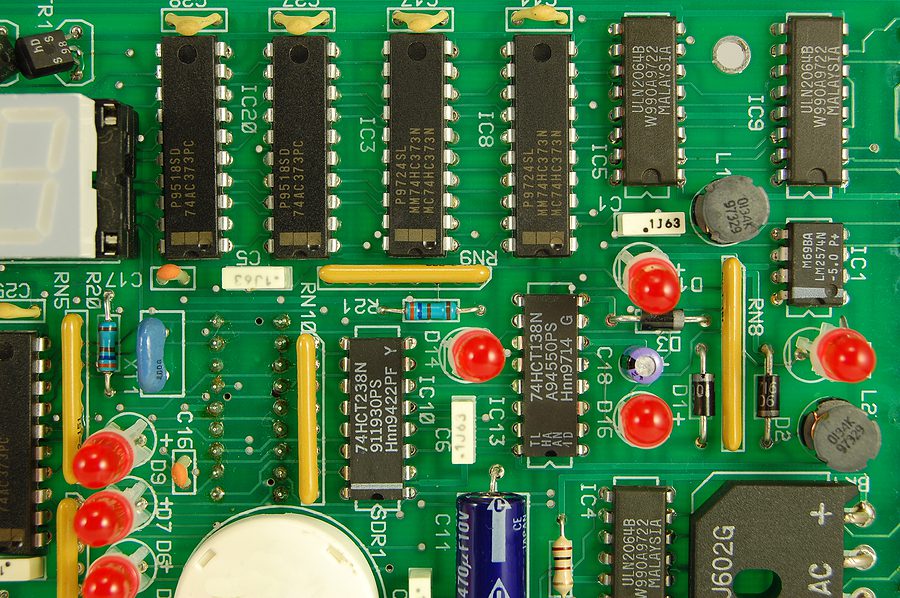

What Makes a Great PCB Manufacturing Partner?

Choosing the right electronic contract manufacturer can make a big difference in the success of your next product. Thankfully, there are some easy ways to vet a new partnership to ensure you’re making the right choice. Here are some things to look for when selecting a manufacturing partner.

Quality Standards

While keeping a budget in mind is necessary for any major business decision, there are certain places you shouldn’t cut corners and that is especially true for electronic contract manufacturing (ECM). Spending thousands of dollars up front on an inferior product will cost you time, money, and headaches in the long run. As the saying goes, “You get what you pay for.” When gathering quotes, find out what’s included in the quoted price, but don’t make your decision based on price alone. The cheapest option isn’t always the best, and an extremely low quote often results in hidden expenses later on.

When searching for a PCB manufacturing partner, ask them how their process works, what materials they use, and if possible, take a tour of their facility. Finding out these details upfront will help you trim down your list of potential manufacturers who won’t be able to live up to your requirements and overall expectations.

Design Support

You may have a good design, but an ECM partner with design support is always a significant benefit. Your ECM can draw from their industry knowledge and expertise to work with and improve your design for the best degree of manufacturability. When you want the most efficient and best design, knowing your manufacturing partner has the right team to assist with that part of the process on-site is essential.

Certifications

Certifications are important because if your ECM has the proper certifications, it shows they’re dedicated to meeting industry regulations and standards and are committed to continuous improvement. In some industries, certification is required to produce a product that meets strict regulations. Before starting your next project, ensure that your ECM has the proper certifications and capabilities for the job. Some certifications to ask about include:

ISO 9001 – The most widely recognized quality certification that demonstrates statutory and regulatory requirements and customer satisfaction.

NIST SP800-171 – Requires that any non-federal computer system must follow strict guidelines to store and process Controlled Unclassified Information (CUI).

AS9100 – An aerospace quality management system considered a highly stringent quality standard.

ITAR (International Traffic in Arms Regulations) – This certification from the United States Department of State controls the importing and exporting of sensitive defense-related materials and information.

IPC and J Standards – These include electronic workmanship certifications for soldering cables and circuit board assemblies.

Communication Skills and Responsiveness

Communication with your ECM is imperative for a successful outcome, so if a prospective ECM isn’t answering or returning phone calls, move on. To ensure an ECM is working for you, consistent communication and responsiveness is a must. Together, you and your ECM should operate as a team prioritizing transparency and honesty throughout every stage of the project.

It’s not too much to expect an ECM to respond promptly to your questions, behave professionally, and strive to make the best decisions for your company-basically acting as an extension of your team. Finding an ECM partner who is proactive, innovative, and responsive isn’t optional; it’s a must.

Low Volume Runs

Is the ECM you are considering capable of scaling production to meet future needs and capable of prototyping and small runs? PCB assembly can begin with prototyping to allow for limited or low volume runs to ensure functionality before a full run. You need an ECM with cutting edge infrastructure and specialized components necessary to build parts and products to the exact specifications required; one which incorporates traditional and modernized technologies to meet your specific needs.

Start Your Quote Now!Realistic Project Timeline

Many tasks may take longer than anticipated; however, partnering with the right ECM facilitates proper expectations. When project management is lacking, budget estimates and project delivery timelines can be off, causing everything to spiral out of control quickly.

Multi-Industry Experience

An ECM partner with multi-industry experience who understands the specific requirements associated with your industry will be extremely helpful. Not all ECMs have experience in all industries. A partner who understands compliance with industry laws, regulations, guidelines, and specifications can positively affect each phase of the manufacturing process.

Packaging and Shipping

Finding an ECM partner who offers product fulfillment services, including direct shipping to the distributor will save you time and money. Transitions can be a pain point for many projects, with moving products to your consumer potentially being the most painful. Packaging and shipping are services that usually require the support of a subcontractor, but a superb ECM partner can confidently handle the packaging and shipping hassles for you.

Why Choose Levison Enterprises?

The value of choosing a great PCB manufacturing partner over an okay one cannot be understated. When you are set up for success, your project will be ready for delivery and ready for market that much faster. If you’re looking for a domestic turnkey electronic contract manufacturer for your next project that checks all the boxes, consider Levison Enterprises. Contact us today for a quote.