Is Your Electronic Manufacturing Partner Ready For Your Project?

You have a lot of choices when it comes to partnering with an electronic contract manufacturer. So, how do you know the electronic contract manufacturer (ECM) you choose will be ready for the challenge of your project?

The best way to avoid partnering with an ECM who isn’t capable of successfully managing and manufacturing your product is by looking for indicators that DO make them the right choice.

Experience

Do you want a company to cut its teeth on your project? The answer should be a resounding “No.”

You want an ECM with experience in manufacturing electronics, but more specifically one who has built a product similar in size, quantity, and technical specs to yours who also has experience with and an understanding of your industry. The more projects under their belt the better. Working with an established electronic contract manufacturer who has substantial experience and a trustworthy reputation should be an expert in the industry that can be relied on to produce quality products.

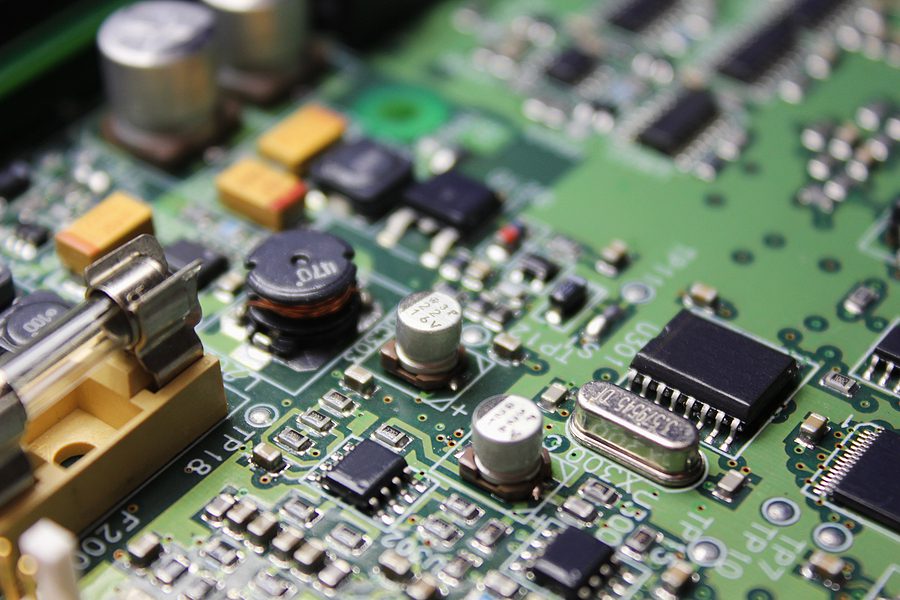

Equipment

Your manufacturing partner should already have the technology, tools, equipment, and machinery in place to get the job done. Without it, you can’t be guaranteed your ECM will actually be able to successfully complete your project and/or meet your quality standards and timelines.

Knowledge

Is your ECM familiar with the requirements of your industry? Not all contract manufacturers have knowledge of all industries. Following unique laws, regulations, guidelines, and specifications will affect every stage of the manufacturing process, especially if the company is not familiar with them. You need to be assured your ECM can handle the project and that it will comply with your industry specifications.

Engineering Support

Your ECM needs a team in-house with some serious technical know-how. This is achieved with dedicated engineering support. Your manufacturing partner should have a team of experienced, knowledgeable engineers, project managers, and others overseeing each stage of the manufacturing process. They will be on hand to detect potential problems and offer innovative solutions.

Certifications

The certifications held by an ECM are a clear indicator they work hard and pride themselves on excellence. Certifications such as AS9100 and ISO 9001 mean your ECM meets the standards and requirements of the certifying organizations.

PFMEA

Process Failure Mode and Effect Analysis (PFMEA) is a proactive tool used to identify, evaluate, and prioritize potential weakness or failure modes in a given system. An ECM that uses a PFMEA is going out of its way to protect your product with the end user in mind.

PFMEA services provided by your manufacturing partner are an excellent way to plan for the worst-case scenario. This helps pre-plan for unexpected challenges and ensures everything will function properly as it should.

Continuous Improvement Processes

An ECM that follows a continuous improvement approach to manufacturing operates on a higher level. This adds so much value to their products, services, and processes. An ECM with a clearly defined plan to value improvements in their processes is one who is dedicated to the success of every project. That is the kind of partnership you’ll want to have with an ECM.

Manufacturers that employ a continuous improvement process, such as Plan-Do-Check-Act, tend to work more efficiently. Having a plan like this in place identifies opportunities that benefit their business without interrupting daily tasks. These benefits include increased productivity, improved quality, and lowered costs, which are then passed along to their clients. Additionally, these kinds of processes keep the project team cohesive, and nothing bad ever comes from an efficient team who is always on the same page with each other and with you.

Supply Chain Management

A supply chain management system is invaluable and ensures manufacturing runs smoothly. True supply chain management involves every aspect of supplying a component including forecasting, sourcing, and counterfeit parts avoidance, not just ordering parts. Without a solid supply chain management system, there is a big risk of wasting time tracking down various components for your product.

Counterfeit Parts Mitigation

You never want to run the risk of fake or faulty components being used in your project. Your manufacturing partner must have an excellent counterfeit mitigation plan in place. This should include a trusted network of vetted suppliers along with regular parts inspections and testing.

It is hard to turn over a project to an ECM when you’ve worked so hard to bring to fruition and you’re concerned about the protection of your intellectual property. You need an ECM with all of these characteristics to ensure your project is safe, successful, and in trusted hands. Levison Enterprises will work hard to make your project a success.

We have a full range of capabilities and experience, and the industry certifications we have earned proves we value the high standards and technical know-how to handle your project. If you are looking for a manufacturing partner with high-quality standards, contact Levison Enterprises for a free quote on your next project.

Start Your Quote Now!