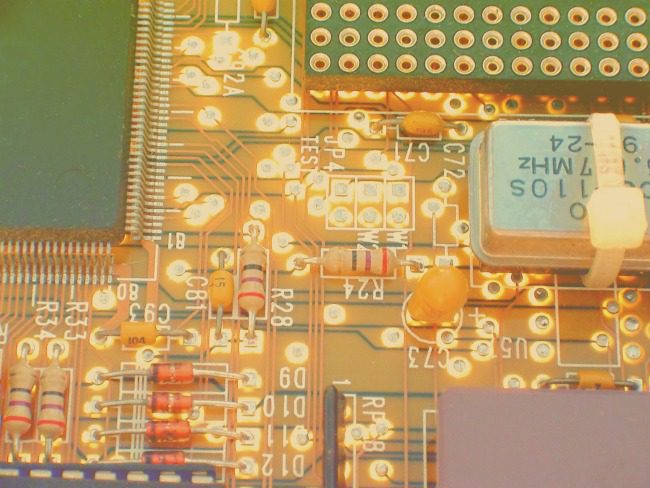

Save Money & Ensure Quality: Source Your Materials With Your ECM

Every manufacturer has two priorities that guide every decision. They want to make and deliver a high-quality product while saving every dollar on materials, assembly, and delivery. This is where a partnership with the right electronic contract manufacturer (ECM) can make a significant difference.

The best electronic contract manufacturers will have systems and relationships established that ensure the quality of sources and materials – at a better price than you could independently.

Leverage the right partnerships from your electronic contract manufacturer to save you money and ensure quality on your next electronics project.

Quality Control You Can Trust

Sourcing your own materials can mean greater control of your project, but sourcing materials is a time-consuming process. Ensuring quality means knowing the source of all the materials you use. If you attempt to source your own parts to save money, you may not have the systems in place to receive and inspect the materials.

This is where your electronic contract manufacturer‘s relationships and vendors can help you on your project assembly or build.

Each and every part that is custom made for your project, by a vendor, should be inspected by your ECM once it arrives in the facility to make sure it conforms to your project specifications. By ordering the parts for you through their trusted vendor network, your ECM will have a paper trail and documents to support your parts and components.

Some parts come shipped with a certificate of compliance, or a C of C, that comes from the manufacturer. This statement ensures that they have inspected the part themselves and will stand behind the quality. Parts that come with a C of C do not require the same level of inspection because the EMS trusts its quality.

Purchasing your materials and parts from online sources, like Amazon or Ali Baba, may save you money, but do you really know these materials? These parts don’t ship “from Amazon”. They are sold by third party vendors who may or may not sell knock off or defective parts. Your source material is unknown. The quality of your final product is dependent upon putting it together with quality parts.

The Best Price

The best quality materials at the lowest cost – that’s the goal of independent sourcing. Your ECM’s buying power is leveraged when working with many customers on many projects at the same time. Instead of buying a few parts just for your project, the ECM will buy hundreds of pieces for other projects that require that same part. That ability to buy in bulk means you receive the best price for your materials.

Your ECM should also have backup contingencies for hard-to-find materials and parts. You may want specific tubing in a certain color, but it is out of stock or unavailable. An ECM can find tubing in a different color but with no other significant differences in the way the part performs from their vast network of vendors and suppliers. When your engineers put the bill of materials or BOM together, they may use the part numbers specific to a specific part or material vendor.

This can be an area of cost savings for you!

Oftentimes, your ECM may be familiar with this vendor. Your ECM can identify that part and use their network to your benefit or often find another vendor with a better price. On large quantity purchases that can mean significant savings.

Streamlined Delivery

One of the key priorities for any manufacturer is the end product delivered on time, but ensuring on-time delivery can be complicated. By having your parts and materials sent directly to your ECM, you avoid the need to have it shipped to you and then to your ECM.

This will reduce your overall production time. Your ECM will often have terms with vendors that get them free shipping – another saving for you.

Using Material Resource Planning or MRP software helps your electronic contract manufacturer know when all parts of a project will arrive. If it is a recurring project, your electronic contract manufacturer will know when the inventory of a particular part is getting low and submit an order with enough lead time to avoid disrupting production.

Knowing a quality control system is in place, costs are being kept as low as possible, and the delivery process is hassle free, may make sourcing material through an electronic contract manufacturer the best option for your project.

At Levison Enterprises, our customers enjoy quality control they can trust, the best prices available, and a streamlined delivery. Contact the Levison Enterprises team today to find quality materials at an affordable price for your assembly or build.