Benefits of Utilizing a Single Source Electronic Manufacturer for Your Complete Assembly

Are you looking to streamline your assembly process, reduce your shipping timelines, and possibly reduce your overall cost? Who isn’t? Your best bet may be a single source electronic manufacturer or turnkey ECM.

Consider why a single source electronic contract manufacturer might be the best option for you.

A Limited Number of Vendors Can Create Cost Savings

Too many cooks in the kitchen ruin a soup, and it’s no good for your project either. When you limit the number of vendors for a single project, you simplify your process and enjoy cost savings.

The estimate for a full assembly from an ECM will likely be less than the combined estimates from vendors for producing the printed circuit board, another performing the cable assembly, and yet another completing the full assembly.

One vendor providing the full assembly can take advantage of efficiencies in moving from one step to another to deliver a better price.

Additionally, having all the work done in one location saves on total shipping costs, further reducing the expense of completing the project.

Flexibility and Efficiency Combined

Changes in design are sometimes unavoidable, even once the project has reached the manufacturing stage.

Should a change need to be made, communicating with one vendor rather than attempting to coordinate the changes with multiple vendors is not only less hassle, but it also helps ensure there are no errors arising from the change due to missed communications.

A strong ECM also offers the flexibility of being able to proactively anticipate problems with cable assemblies or cabinets before reaching that stage of the production.

Leveraging the benefits of working with an existing vendor can reduce costs and improve production efficiency throughout the process.

Full Troubleshooting After Delivery

If there is a problem with a product after the project is completed, working with a single vendor makes it faster and easier to get to the root of the problem and make corrections.

In the event a problem arises, a single source ECM becomes your ally, working with you to diagnose and correct the problem. When working with multiple vendors, there is often a delay in determining where the source of the problem lies, and each vendor is likely to believe the problem is in one of the other areas.

A single source ECM is as motivated to troubleshoot the problem, correct it, and has the familiarity with the entire project to be able to solve it quickly.

Better Packaging and Shipping Solutions

A single source ECM will work with the project directly and have knowledge of the entire scope of the build.

This allows the ECM to best provide packaging and shipping solutions that will work best for your project.

This final stage is an often-neglected afterthought of a project, but getting the packaging right is important for ensuring safe delivery.

If a project requires exporting to different countries, getting the right shipping solutions becomes especially important, and is an area where an ECM familiar with the project and experienced in dealing with shipping logistics can provide cost savings and eliminate headaches.

Levison Can Deliver It All

Levison Enterprises has the capabilities and experience to be your single source ECM. We’ll assign a dedicated team member devoted to your project who will essentially become an in-house expert on your entire build.

Levison Enterprises has the cabinet assembly capabilities for:

- Backplane assembly

- DIN rails

- Cable assembly

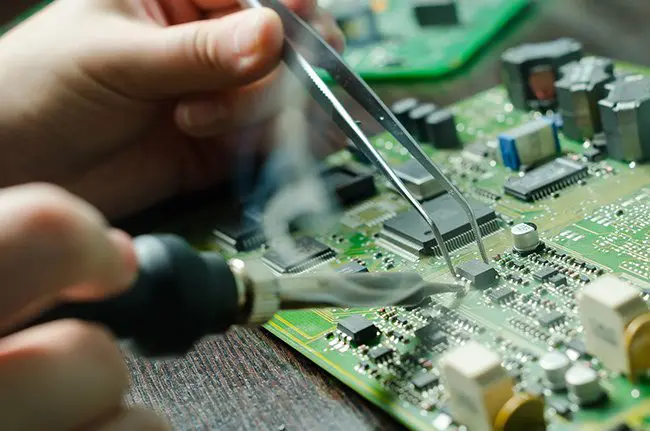

- Circuit board assembly

Let Levison Enterprises put our expertise to work for you. You’ll experience the satisfaction of working with one ECM for the entire project.

Give us a call and learn how we can take your designs to print and build today!