Selecting the Ideal ECM Partner for Your Cable Assembly Manufacturing

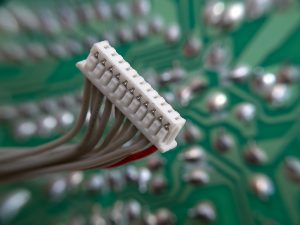

Cable assembly manufacturing plays a critical role in the success of many electronic devices, making it a key factor to consider when selecting an electronic contract manufacturing (ECM) partner. With so many ECM providers to choose from, finding the right fit can be challenging—especially when the stakes are high. While some developers focus solely on cost, those committed to long-term success understand that choosing the right partner involves much more than pricing. Every stage of the manufacturing process, including cable assembly, deserves careful evaluation.

Understanding the Value of Choosing a Domestic ECM

Before you consider any other factors of what makes an ideal ECM, think about only looking at domestic partners. While there are many overseas options that may try to woo you with promises of lower costs, there are typically more drawbacks than benefits to choosing an overseas partner.

Increased delivery time, communication barriers, concerns about counterfeit components, and delays in manufacturing can actually increase the overall cost, in addition to making the entire process far more difficult.

By choosing a domestic ECM, you can have the entire process handled by one facility, avoiding transitions. Without language and time zones barriers, communication becomes far easier, ultimately translating into cost savings. Cable assembly manufacturing can quickly derail a project if it is not done correctly or with the right materials, and having a domestic ECM who has been with your project from the start is the best way to ensure your device manufacturing is a success.

Does the ECM Have a Vetted Supply Chain?

Supply chain concerns are less of an issue than they were several years ago, but there are still delays and shortages that can impact cable assembly manufacturing. When you choose an ECM with a vetted list of suppliers, you can trust that genuine parts are used in your build. They have a plan in place to get the components you need for every stage of your manufacturing. Vetted supply chains greatly reduce the risk of counterfeit components, which can have a serious impact on functionality and reliability.

Does the ECM Have Experience in Your Industry?

The cable assembly portion of electronic manufacturing is just as important as the design, PCB assembly, box build, or any other part of the process. Experience in your industry matters. An ECM who has worked with a company in your field will understand the intricacies of what can impact the operational efficiency or functionality of your device. This includes how the device will be used, the operating conditions, and any other requirements that will make a difference. A cable assembly for a medical device will likely look very different from a cable assembly intended for an aerospace application. Your ECM will likely have experience in many different industries, but it is still important to make sure that whoever you chose to partner with knows what you expect from a finished product.

Does the ECM Hold Relevant Certifications?

If you are working in a highly regulated industry, you already understand the need to have all partners involved in the process hold relevant certifications. However, even if you are not working in an industry with precise standards and regulations, it is still beneficial to work with an ECM who prides themselves on both obtaining and maintaining certifications. Quality certifications, such as ISO 9001, demonstrate that your ECM has a culture of continuous improvement and will strive to hold themselves accountable for every piece of the manufacturing process, including cable assemblies. With the right documented quality assurance processes, the methods and systems used to ensure precision work and reliable functionality will be strong.

Can Your ECM Meet the Application Requirements?

Just as your ECM needs to understand the needs of your industry and application and hold the relevant certifications, they will also need to have the appropriate skills and technology to meet your requirements. Electronic devices vary greatly in size, form, and function. If your device is large and will be operating under extreme conditions, your ECM has to have the skills and technology available to ensure durability to the end user. If the device is miniaturized with small, intricate connections, this is a very different skill set that will require technology to handle the precision that goes into the cable assembly for a small device.

Can the ECM Handle the Full Project In-House?

Most errors in electronic manufacturing happen during transition points in the project, where communication breakdowns, the threat of damage to an unfinished product during transport, and chain of custody are a concern. Therefore, it makes sense for the ECM you choose to have the capabilities to handle the entire process, including cable assembly, in-house. These turnkey facilities can provide everything you need for the entire process, including design support, DFM analysis, prototyping, PCB assembly, cable assembly and wire harness manufacturing, box builds, testing and quality control, and delivery. This means they will have a full team that can handle any issues that may arise, including on-site engineers, who will be able to troubleshoot problems at any stage.

You always have options for cable assembly manufacturing, but when you weigh all the relevant factors, the best partners will reveal themselves. Outsourcing your electronic manufacturing should not feel like a risk. A good partner will be the right balance of cost-effectiveness, reduced lead-time, and high-quality results. Finding a domestic, turnkey ECM with the right experience in your industry is critical to success, but by asking the right questions, you can find a partner that will take your device all the way through the process.

The Ideal ECM

Choosing the right ECM partner for your cable assembly manufacturing isn’t just a box to check—it’s a strategic decision that directly affects the performance, reliability, and longevity of your final product. The ideal partner goes beyond offering competitive pricing; they bring industry-specific experience, a vetted supply chain, in-house capabilities, and a commitment to quality. At Levison Enterprises, we understand that cable assemblies are more than just wires—sometimes they’re the backbone of your device. When you’re ready to work with a domestic ECM that delivers turnkey solutions with precision and accountability, we’re here to help move your project forward. Contact us for a quote on your next cable assembly.

Start Your Quote Now!