How to Keep Counterfeit Components Out of Your Electronic Assembly

One significant concern of electronic assembly manufacturer is the reliability of the components being used. Counterfeit electronic components have long been an issue for manufacturers, and the counterfeit industry continues to thrive by adapting new ways to mask part authenticity.

Counterfeits are usually produced in one of two ways:

- Old parts are refurbished and resold as new

- Old parts are relabeled and sold as different parts

This is a major concern for manufacturers. Often, these components can mirror the parts you ordered and don’t always fail initial testing. However, down the line, they can cause major problems as they’re much more likely to malfunction than genuine parts.

Look for a turnkey electronic manufacturer with advanced capabilities and industry-recognized certifications to ensure you have the right partner and prevent counterfeit components from entering your electronic assembly.

Vetted Supply Chain

Having a vetted supply chain at your disposal is crucial to ensuring a quality product. If you use non-vetted suppliers, you risk parts being incorporated into your product that are low quality and possibly counterfeit. Partnering with an ECM who has a network of vetted suppliers will help with parts procurement, ensuring all components have been tracked through an established supply-chain management process. With a vetted supply network, you can feel confident the parts are high-quality and legitimate.

Counterfeit Component Mitigation

Since they can be difficult to distinguish from legitimate components, it’s essential to partner with an ECM who has an established mitigation process in place. This means they developed policies and procedures for avoiding counterfeit components, including how to:

- Avoid purchasing suspected counterfeit parts

- Handle and track incoming and outgoing parts

- Manage and dispose of suspected counterfeit parts

A reliable ECM partner implements counterfeit avoidance and management training programs, including:

- How to inspect parts and identify counterfeit components

- Training to all employees handling parts

Communicating directives efficiently ensures everyone understands the problem to properly address it, including employees that order, receive, handle, inspect, and ship parts, as well as management.

Testing

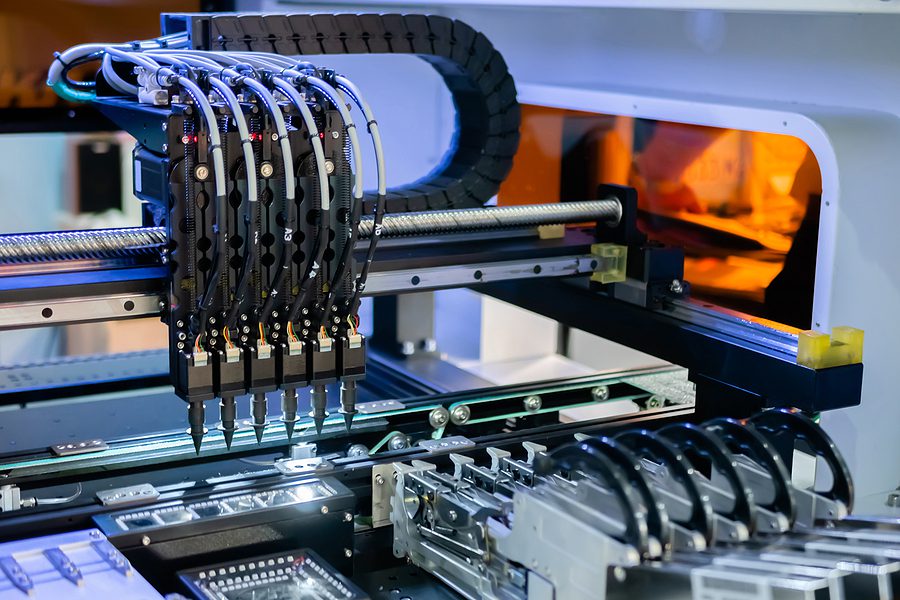

Counterfeit parts have been known to slide through undetected when you don’t have a thorough testing process in place. Working with an electronic manufacturer who performs rigorous testing ensures that counterfeit parts have a better chance of being caught.

Experienced ECM manufacturers know how to perform inspections to look for indents, thickness, edging, texture, and pins which are all useful in identifying potential counterfeit components.

Certifications

With quality certifications in place, you can feel confident you have a partner who values consistency and safety, including a final product you can depend on, free of counterfeit components.

Plus, when your ECM partner has the proper certifications in place, it shows they’re dedicated to meeting industry regulations, standards, and continuous improvements. While certifications aren’t required for a business to market itself as an ECM, they are necessary to work with certain industries.

Some certifications to look for include:

- FDA Registration

- CMMC

- AS9100 Certification

- ISO9001 Certification

- ITAR Registration

- IPC and J Standard Certification

- NIST Certification

Quality Management System in Place

Look for an ECM partner with a quality management system in place who is ISO 13485 certified. It is the quality management system (QMS) standard for the medical device industry, outlining specific requirements for implementing a QMS at any facility involved in the design, production, installation, or servicing of medical devices.

Medical device companies seeking a PCB design and assembly partner have many critical factors to consider, all resulting in the end user’s safety and risk. Working with a manufacturer who is ISO 13485 certified gives OEMs greater assurance their devices will pass the strict quality and safety requirements, regardless of the industry.

When a contract manufacturer implements a quality management system, has documented processes, procedures, and responsibilities in place to achieve quality objectives and policies. All activities and processes are coordinated to meet customer and regulatory requirements, as well as continually improve overall effectiveness and efficiency.

Choose Your ECM Partner Carefully

If you want a quality finished product, you need to find a partner focused on quality assurance during the PCB assembly, prototyping, testing, and manufacturing. You want an ECM partner with:

- Component management and vetted suppliers

- Experience in multiple industries

- Continuous improvement processes

- Streamlined delivery

- Testing and inspections

- Certifications

Does this sound too good to be true? If you partner with Levison Enterprises, you get it all. In addition to being ISO 13485 certified by NSF-ISR, our engineering and design services ensure your project will be put through rigorous testing before it moves into production. Once in production, your project continues to be tested and checked, helping to ensure counterfeit components stay out of your assembly. Contact us today to learn more.