Electronic Manufacturers Create Efficiency in PCB Manufacturing and Assembly

Electronic manufacturers can seamlessly take your product from design to fulfillment without hitting novice bottlenecks. They know your industry, and have a broad knowledge of many industry standards and regulations.

ECMs have a solid plan of action and processes in place. They can suggest ways to improve your design and streamline the manufacturing process overall for reliable timelines and accurate parts forecasting, and they understand your industry standards.

Below are eight ways an Electronic Contract Manufacturer (ECM) can help you create efficiency in PCB manufacturing and assembly:

1. Comprehensive Capabilities

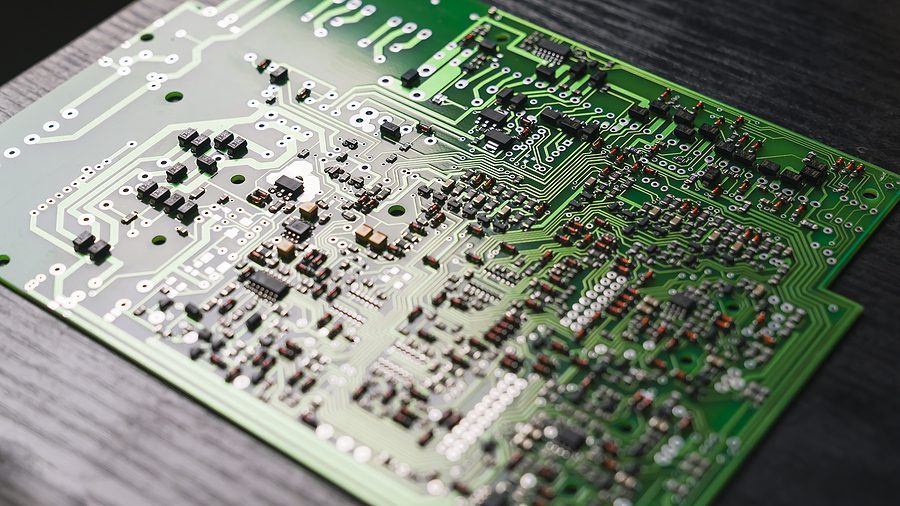

Your business may not have the resources to acquire cutting-edge and innovative technology. Since ECMs are in the business of producing innovation, they make investments in technology and equipment to deliver your project faster and often more economically. You can take advantage of their comprehensive capabilities and equipment to make the most innovative products in the most efficient manner possible.

2. Technology and State-of-the-Art Equipment

Your products will be built with state-of-the-art equipment and technology. The most up-to-date equipment and technology are critical to staying relevant in any industry. An ECM partner has the means to invest in what is needed for today’s electronic devices.

3. Experts on Staff

Your electronic contract manufacturer also includes highly trained and, in some cases, certified assembly teams. These employees receive ongoing training to keep up with the latest trends and industry demands. This ensures your product gets the best treatment on every product that passes through their hands.

4. Testing

Before releasing your product to the public or incorporating it into final assembly, it’s essential to ensure it functions properly and meets quality standards. Your ECM can offer functional firmware and software testing services for the products it builds. This troubleshooting process helps identify and resolve potential problems before the product gets into final assembly or your consumer’s hands. This minimizes the need for repair services and sending replacement units and reduces the risks of a product falling short of consumer expectations.

5. Prototype

Prototyping is a necessary stage of the manufacturing process. After the design and before production, there is a window where you, together with your electronic manufacturer, can take a thorough look at the design and components of your project. A prototype will allow your project to move from the theoretical stage to the concrete stage, which is your opportunity to identify and address potential problems.

6. Vetted Supply Chain

An electronic assembly partner will have vetted suppliers with supply chain management processes in place, which means part obsolescence and counterfeit parts are much less of a concern.

7. Accurate Forecasting

An experienced ECM has good supply chain management, in-house engineers, and the capability to accurately forecast and mitigate parts obsolescence. They can determine the availability of components and be able to accurately forecast the risk of parts becoming obsolete. This allows them to stock up as soon as they are aware a part may quickly become hard to find. A contract manufacturer proactive in parts obsolescence will have an existing trusted network of vetted suppliers to turn to when a part is in danger of becoming hard to find. This will also enable the assembler to determine if there is an adequate substitute for the part or an appropriate aftermarket source.

8. Counterfeit Component Mitigation Process in Place

A counterfeit electronic component is an imitation, unauthorized, or modified electronic component that is sold and presented as a legitimate component. In some cases, it can also be a used component that has been altered to be misrepresented as new. Counterfeit parts can be challenging to distinguish from legitimate components, especially for those unfamiliar with electronic parts and components. Since they can be challenging to differentiate from legitimate components, partnering with an ECM who has a mitigation process, including vetted suppliers, is essential. A reliable ECM will understand how to avoid counterfeit components and will know how to inspect and look for indents, thickness, edging, texture, and pins, which will help catch any potential counterfeit parts.

Why Levison Enterprises?

Being able to trust your ECM partner is everything. A reliable electronic contract manufacturer will help ensure industry compliance and safety. They maintain specific quality standards and certifications regardless of whether you require them for your project. An ECM can help deliver a quality project within a tight timeline, handling every aspect of production. Levison Enterprises will be a valuable partner throughout your design and production process by utilizing expert staff, state-of-the-art equipment, and design and testing capabilities. Contact Levison Enterprises today to learn more about how we can work together to create your next project.

Start Your Quote Now!