Cost Estimation in Electronic Manufacturing: Factors to Consider

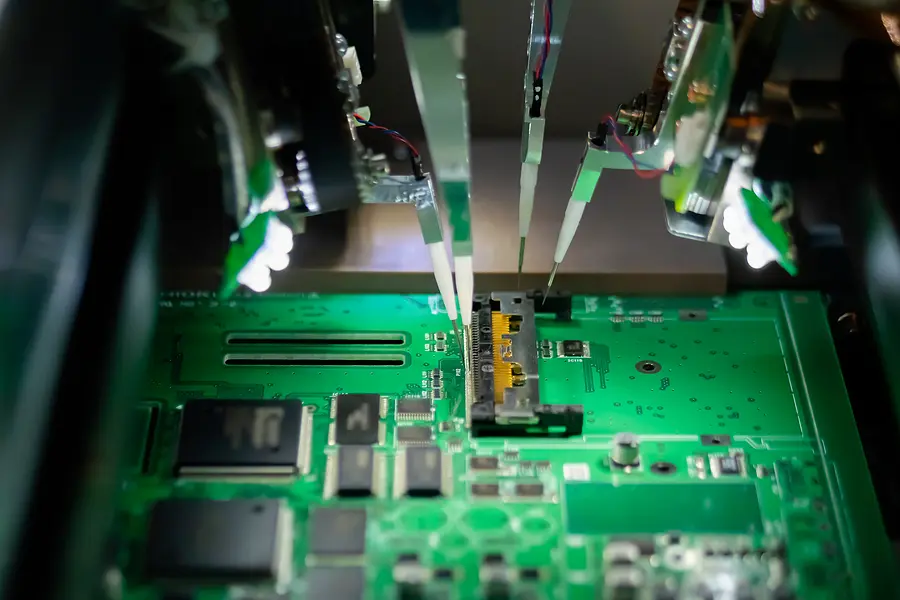

When you have finished the design and development of your new device and are ready to bring your product through the manufacturing process, you will likely start by meeting with several potential electronic contract manufacturers and obtain cost estimates for production. Understanding the factors that go into this estimated cost can help you accurately compare facilities, especially when considering domestic and overseas options.

What Components Go Into Determining Cost?

There are many components that go into determining the cost estimate for electronic contract manufacturing. The main factors include:

- Number of Components: more components will increase the cost.

- Type of Components: different components have different price points, and some PCBs require specific components to function optimally.

- Number of Holes Necessary and Hole Size: smaller holes will typically have increased tooling costs, and a larger number of holes will increase your cost per board.

- Double Sided or Single Sided Assembly: Double sided PCB assembly will add cost when compared with a single side assembly, as each board will need to run through the assembly twice. Additional layers will also increase the complexity of the manufacturing process, and therefore, have an increased cost.

- Finishes: corrosion resistant finishes, as well as other options, can increase the durability of the PCB, with the cost varying depending on the type of surface finish chosen.

- Compliance Requirements: if a product needs to be ITAR compliant, there may be additional costs necessary to adhere to ITAR requirements.

During your initial consultation with an ECM, you will go through the requirements for the PCB assembly necessary for your device and how each of these requirements will impact the cost estimation.

Comparing Different Levels of Service

Many ECMs offer additional services that can be done prior to and after manufacturing. In pre-production, some ECMs will offer design inspection, and a Design for Manufacturing review. While these are an additional cost, going through pre-production inspections, reviews, and adjustments to the design can ultimately bring the manufacturing costs down. During the DFM process, new layouts and components can be suggested, which may decrease the cost of the board. Prototyping or testing runs are often suggested for new designs to ensure functionality, which is far more cost-effective than determining an issue after a full-scale run. Additional services can greatly increase the overall quality and functionality of the final product.

How Does Production Volume Factor Into Cost Estimation?

Volume discounts will make a difference in the cost estimate you receive from your electronic contract manufacturer. As the production amount you require increases, the cost per unit will decrease. Many ECMs will offer several price tiers. A large-scale run will typically be more cost-effective than a small run. However, while volume discounts are desirable, there is a definite advantage to beginning with a prototyping or small-scale run, particularly with a new device. Many high-quality ECMs will offer this service for new devices, moving on to a larger, discounted run once the final design is perfected and testing is complete. If you are working with a new design, it is worth discussing this during the estimate process.

Difference Between Overseas and Domestic Production

With all the factors that go into determining the cost of electronic manufacturing, understanding the value of the pricing structure is important when choosing the best ECM for your needs. It may be tempting for some designers and developers to consider outsourcing their PCB manufacturing to an overseas electronic contract manufacturer, as many of these facilities offer low initial estimates for production.

However, in many cases, the overall cost ends up being lower when developers partner with a domestic electronic contract manufacturer instead. There are several reasons that choosing a domestic ECM offers better value. The most practical reason is that while the labor costs of an overseas facility may be lower than a domestic ECM, when factoring in shipping, customs, and tariffs, the cost will likely increase considerably. In addition, because of the less efficient and effective communication with an overseas facility, any issues that arise during the process may not be discovered until further in the production process, requiring a costly rerun to address any issues. Lower cost estimates from these ECMs may also be due to overseas facilities not effectively preventing the use of counterfeit components.

These components can be initially convincing, but have a much higher fail rate and are far less reliable than components procured from vetted suppliers. In some industries, the use of counterfeit components can cause a product to be deemed non-compliant, resulting in penalties. While these are the primary concerns, increased lead time, decreased quality, and poor communication all combine to make the ultimate cost of using an overseas electronic contract manufacturer far more than that of a domestic facility. When comparing cost estimates, it is important to consider all the ramifications of opting for an overseas facility to determine if the reduced quality, increased timeline, and additional fees are really the better choice.

Cost estimates are important when bringing a new product to market. Most developers are concerned with cost-effective outsourcing to increase the overall profitability of the device. However, when comparing estimates, it is important to look at all the factors that will go into determining the cost estimate and weighing them appropriately. Rather than only looking at the final number, consider the value of choosing the best ECM that is committed to producing a high quality product. Levison Enterprises is your one-stop-shop for high quality electronic contract manufacturing. With our experience and skilled workforce, we are confident that we can help you build a better, more reliable device. Contact us to learn more about our extensive capabilities.