Blog

Smart Sensors Improve Predictive Performance in Aerospace Manufacturing

February 2, 2026

Aerospace manufacturing demands an extraordinary level of precision, consistency, and reliability. Every component must perform flawlessly under heat, pressure, vibration, and stress, and even minor deviations can create costly problems. Yet many manufacturers are still operating in environments where monitoring depends on manual spot checks, delayed feedback, and reactive maintenance. When an issue is detected […]

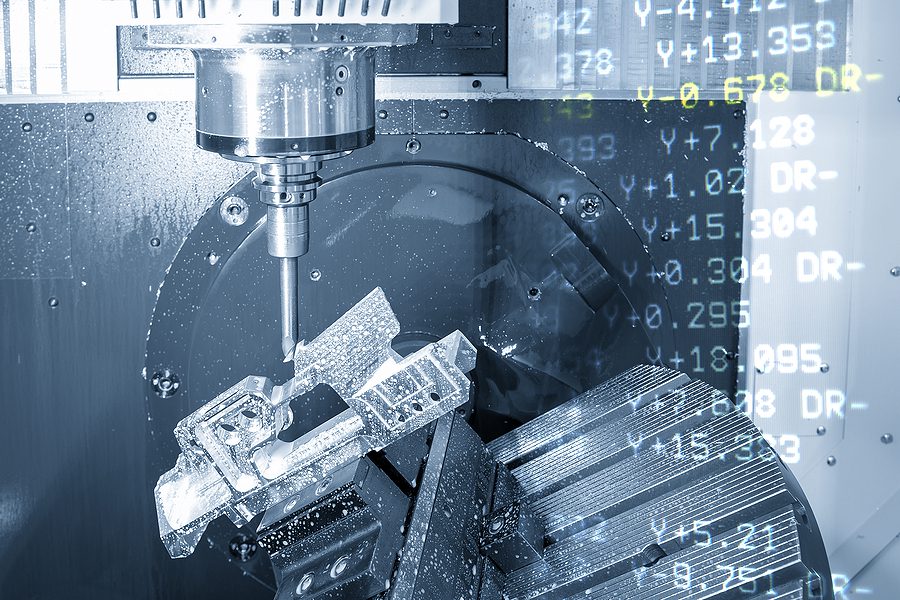

How AI Is Advancing Speed and Precision in Aerospace Manufacturing

January 30, 2026

The aerospace industry operates under extraordinary demands for precision. Every component, from engine turbines to airframe structures, must meet strict standards to ensure safety and optimal performance. Despite advances in manufacturing technology, producing these components remains a complex and time-intensive process. Manual inspections, lengthy production steps, and reactive maintenance schedules can slow timelines, introduce costly […]

Smarter Thermal Management Strategies for Aerospace Electronic Devices

December 26, 2025

As aerospace technology advances, electronic systems are becoming increasingly compact, capable, and powerful. The result is a new engineering challenge that affects nearly every design decision: heat. Managing thermal energy is no longer a secondary concern but a defining factor in the reliability and longevity of modern aerospace devices. Every circuit board, processor, and sensor […]

Building Reliable Medical Devices with Scalable Manufacturing Solutions

December 22, 2025

A brilliant medical device idea can change lives, but even the most innovative concept stalls if it cannot be built with precision, compliance, and scalability. Many companies discover that designing a product is exciting, but the real test comes when it is time to manufacture at scale. Delays, quality issues, and regulatory setbacks can keep […]

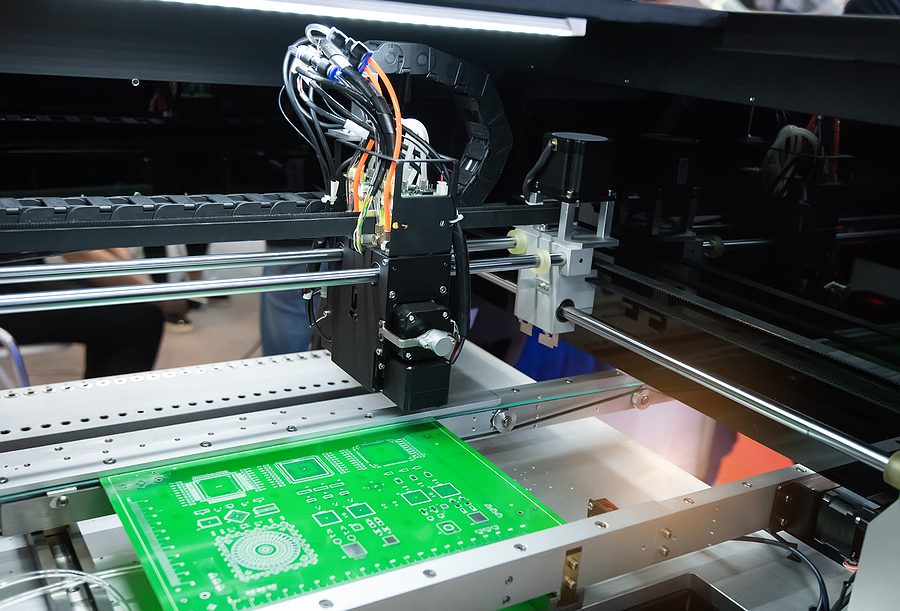

A Strategic Checklist for OEMs Partnering With an ECM for Long-Term Success

December 19, 2025

Original equipment manufacturers (OEMs) rely on reliable PCBs to bring products from concept to market and through years of production. But finding the right electronic contract manufacturer (ECM) to handle that responsibility is no small task. If an OEM makes a poor choice, it can result in missed deadlines, compromised quality, or costly redesigns. On […]

Lessons in Resilience: How ECMs are Bouncing Back from Supply Chain Uncertainty

December 15, 2025

Not long ago, many manufacturers faced an unwelcome reality: parts that had always been readily available were suddenly unavailable. Lead times stretched from weeks to months, and in some cases, even years. Project timelines slipped, costs spiked, and once-reliable schedules became unpredictable. For companies depending on electronic contract manufacturers (ECMs) to build and deliver, it […]

Leveraging COTS for Speed and Cost-Efficiency in Defense Electronic Manufacturing

December 12, 2025

Defense projects face a constant balancing act. On one hand, they demand advanced technology built to perform reliably under harsh conditions. On the other hand, budgets are tightening and development timelines are shorter than ever. Traditional custom-designed components often drive up costs and extend production cycles, leaving program managers searching for alternatives that deliver the […]

Electronic Manufacturing is the Backbone of Mission-Critical Avionics

December 8, 2025

When pilots step into the cockpit, they put their trust in avionics systems that must function flawlessly under all conditions. These systems guide navigation, monitor performance, and safeguard both crew and passengers. Failure is not an option, which is why they require the highest levels of precision and reliability. For the aerospace and defense industry, […]

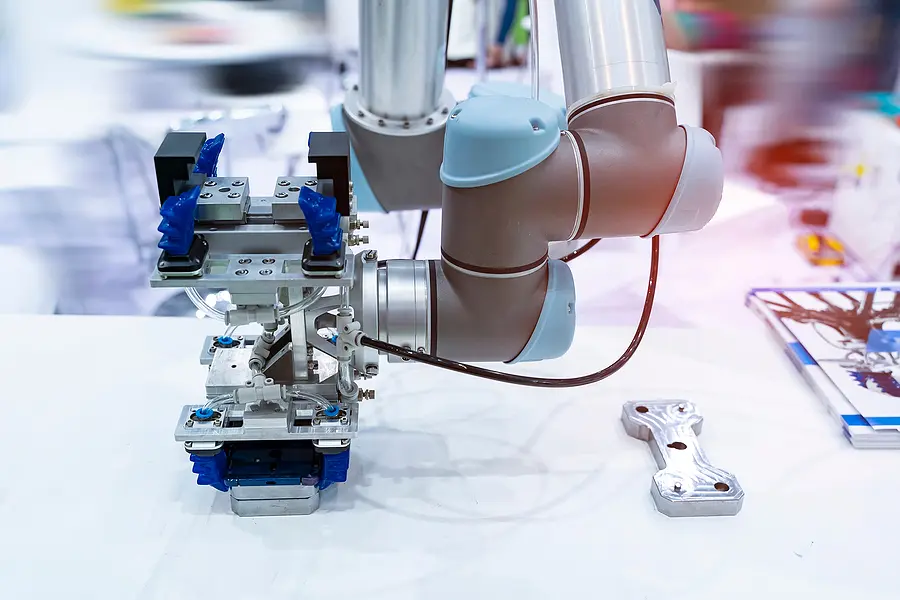

Supporting Product Evolution with Scalable Manufacturing Solutions

December 5, 2025

Bringing a new electronic product to life is never a straight line. Early prototypes often look different from the finished version that enters the market, and even then, successful products continue to evolve. For original equipment manufacturers (OEMs), that evolution brings opportunity, but also new challenges. How do you move from a handful of prototypes […]

ECMs Support Secure Electronic Development for the Aerospace and Defense Sectors

December 1, 2025

In the aerospace and defense sectors, protecting the security of electronic manufacturing is non-negotiable. High-quality, domestic, turnkey electronic contract manufacturers (ECMs) provide the most reliable solution for this critical need. By keeping production in the United States, manufacturers and developers maintain greater oversight and control of sensitive designs, source code, and technical data. Domestic ECMs […]