Blog

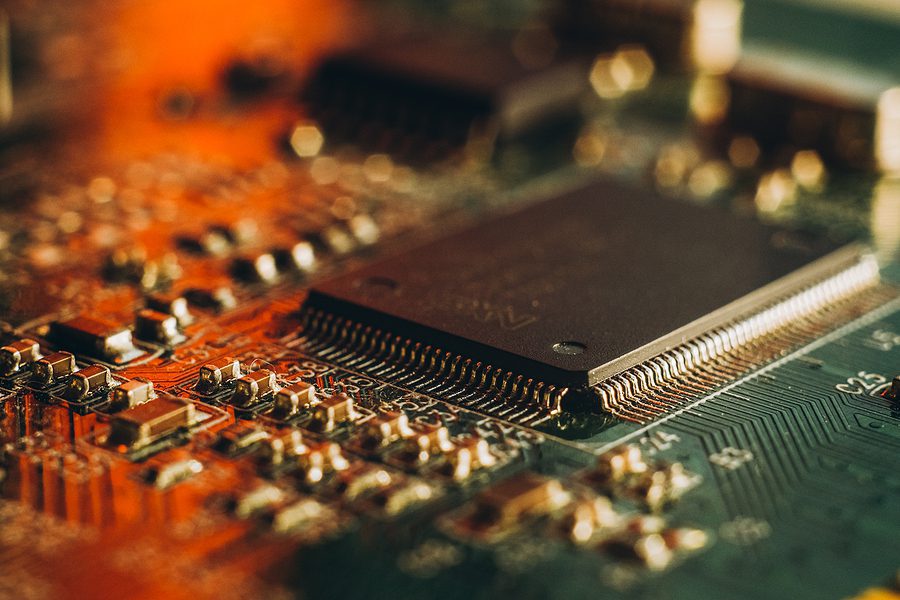

What Factors are Considered When Quoting PCBA?

July 11, 2023

PCB quotes are influenced by a number of factors. When you are first meeting with an ECM to outsource your PCBA, it may be confusing to decipher how the ECM arrived at a particular quote. With the right information about how the factors impact the cost of your project, you can plan and budget for […]

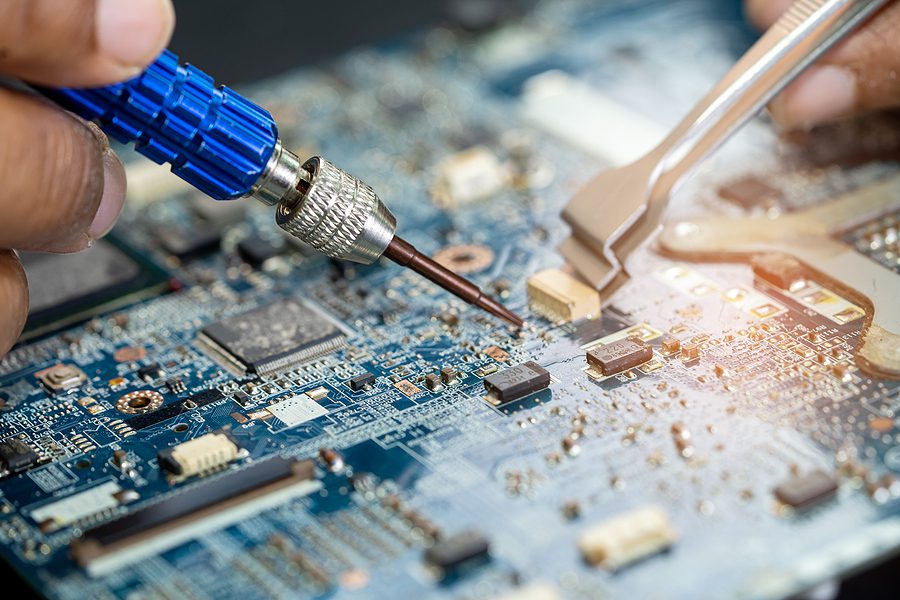

Documents Required for Turnkey Electronic Assembly

July 6, 2023

When you outsource your PCB assembly, providing the complete documentation is essential. Sharing all the design files gives the PCB team all the information necessary to complete the assembly efficiently and correctly. Sharing this documentation provides the electronic manufacturing team not only the information that will allow them to complete the project with the correct […]

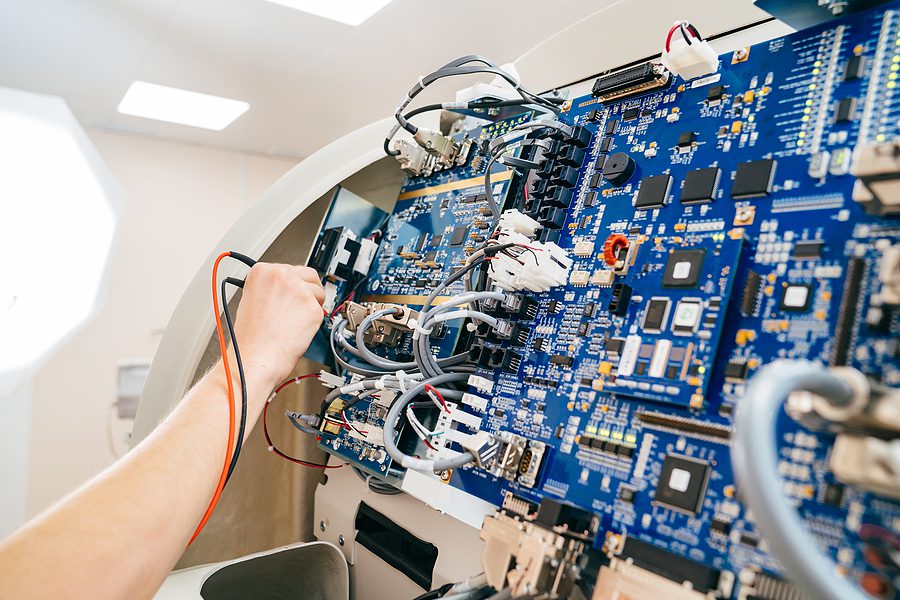

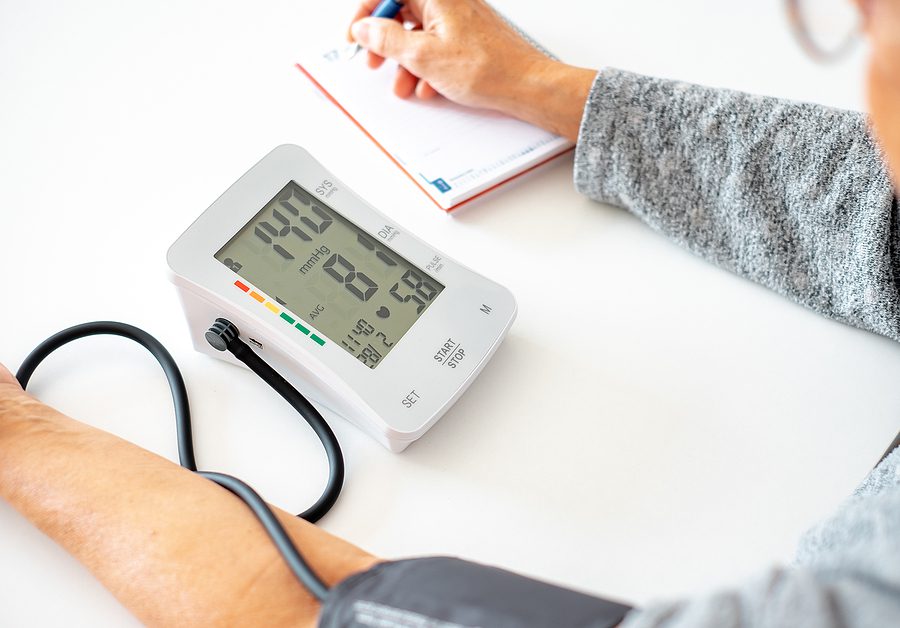

Capabilities Important to Successful Medical Device Manufacturing

April 13, 2023

Medical devices are challenging and complex to produce. The combination of regulatory requirements and critical life-saving components make the development expensive and technically difficult. A domestic turnkey medical device manufacturer with experience, certifications, and advanced capabilities is your best ally to address common pain points in medical device manufacturing from supply chain issues to faulty […]

Choosing the Right Electronic Enclosure for Your Project

April 10, 2023

After your PCB assembly from your ECM partner, it is time to consider the electronic enclosure. This enclosure will protect your PCB from the elements so it can function properly. Wind, water, dust, debris, heat, cold, and humidity can all interfere with the proper workings of your PCB, so the reliability of your enclosure is […]

Packaging and Shipping Goes Beyond Product Protection for Electronic Manufacturers

April 6, 2023

Not every ECM partner will offer packaging and shipping services. When you find an ECM partner who does offer these services, it’s important to understand the additional value you are getting. Electronic manufacturers that offer packaging and shipping understand that they are ultimately maximizing design and functionality.

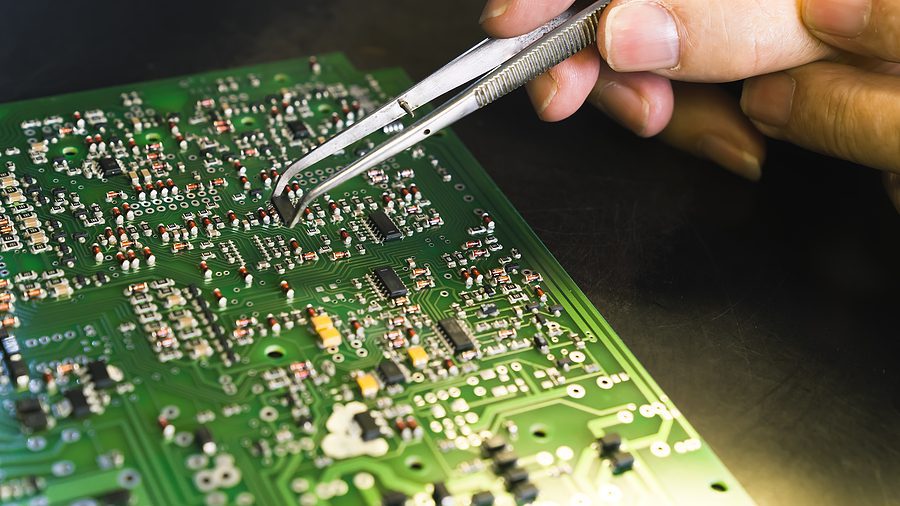

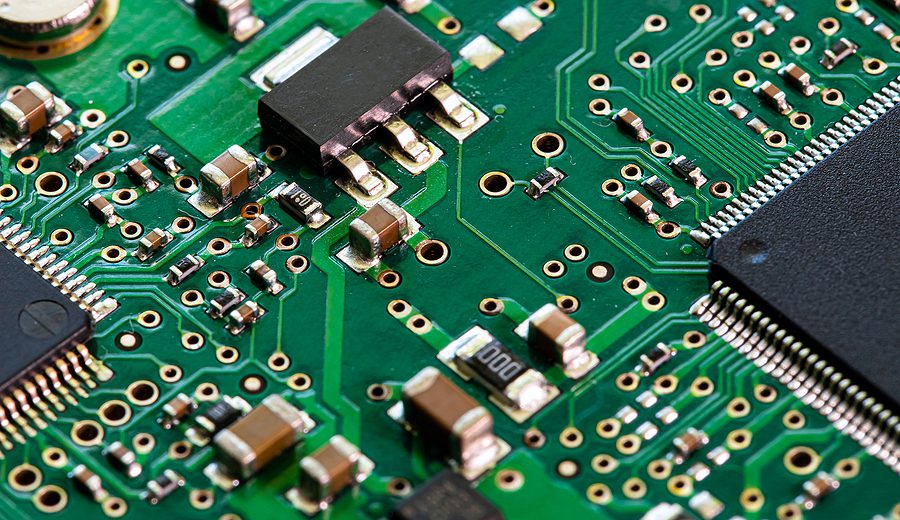

BOM Management is Key to Successful Electronic Manufacturing

March 31, 2023

The bill of materials (BOM) is essential in the design and production phase of electronic devices, starting with printed circuit boards (PCBs). A BOM is like a recipe listing all the items your manufacturing partner will need to build your product. Partnering with an electronic manufacturer with design support is extremely helpful and can make a […]

Save Time and Money on Your Next PCB and Electronic Manufacturing Project

March 29, 2023

Many OEMs consider partnering with an electronic manufacturer overseas to cut manufacturing costs. However, they may not realize it could cost more in the long run due to complications. There is a common misconception that you can save significant money by relying on foreign manufacturers for electronic contract manufacturing, but that’s not the case. Your […]

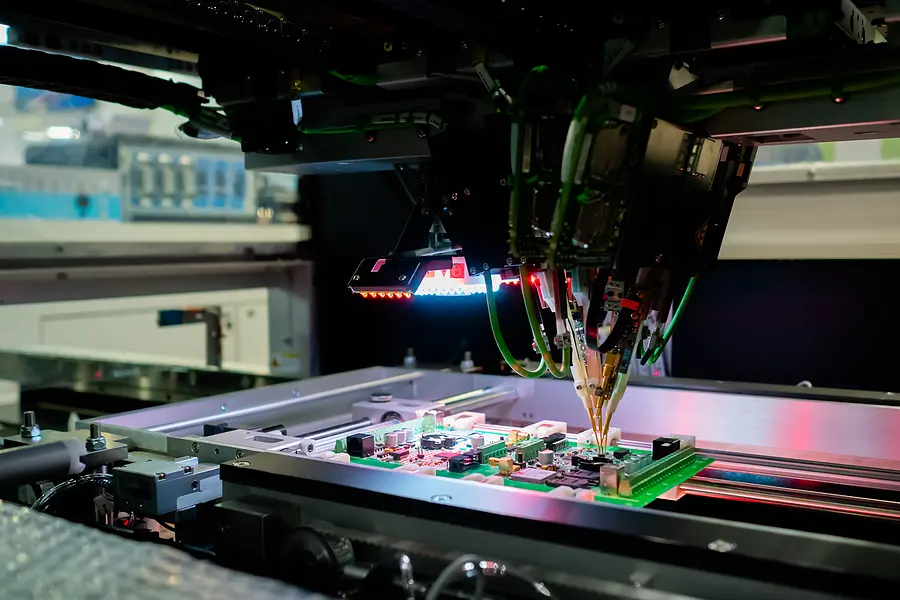

How to Improve PCB Manufacturing Lead Times With an Electronic Manufacturer

March 27, 2023

As the saying goes, “time is money” and that’s certainly the case when talking about manufacturing lead times. Design engineers are being asked to design and bring to market more new products in less time. One way to combat shrinking design cycles is to outsource the fabrication and assembly of the printed circuit boards (PCBs) […]

Your Medical Device Manufacturer can Help Keep Your Medical Device Within Proper Regulations

March 23, 2023

The medical device industry is highly regulated, and for good reason. Regulations exist to protect people by ensuring the safety and efficacy of the product. Obviously, medical device companies want to produce medical devices that are safe and effective, but they don’t always know how to handle the complexities of regulatory requirements. Even seasoned medical […]

Find the Right Medical Device Manufacturer for Your Project

March 21, 2023

Medical device companies understand the significance of selecting the right medical device manufacturer for their medical devices, as it helps them convert their ideas into working prototypes and finished products faster, saving both time and money.