Blog

Sustainable Approaches in Aerospace Electronic Manufacturing

May 9, 2025

The aerospace industry, long associated with cutting-edge technology and innovation, is increasingly focused on sustainability. As global concerns over climate change and resource depletion grow, this sector has embraced green practices to reduce its environmental footprint. This shift is particularly evident in aerospace electronic manufacturing, where companies are rethinking processes, materials, and technologies to align […]

Advanced Manufacturing Solutions for Civilian and Military Applications

May 5, 2025

Imagine a world where buzzing drones seamlessly integrate into everyday life. Farmers monitor crops from the sky, inspectors climb wind turbines virtually, and vital supplies reach remote locations without a hitch. This future is taking flight thanks to the convergence of advanced manufacturing and the booming UAV (unmanned aerial vehicle) market. The global drone market, […]

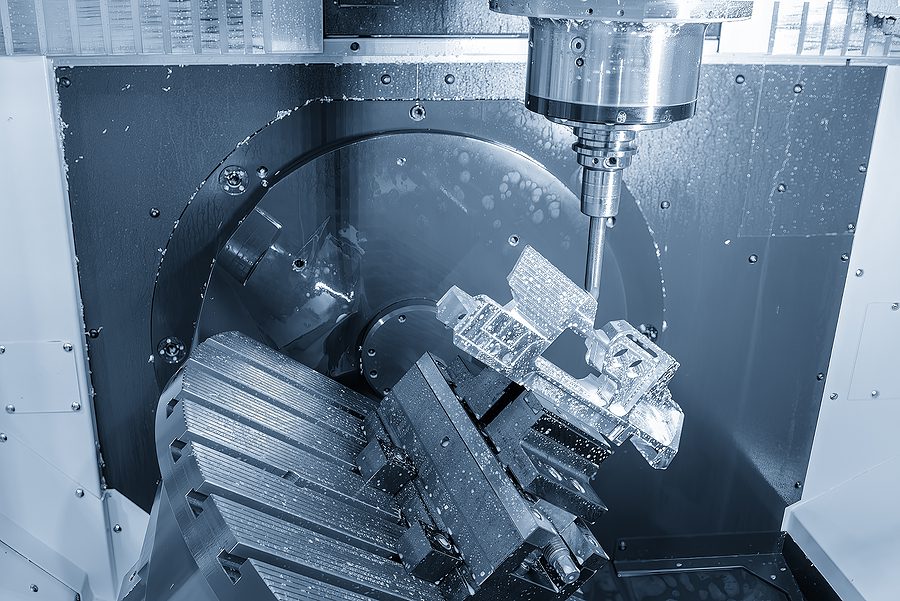

Streamlining Aerospace Manufacturing for Optimal Performance

May 2, 2025

Aerospace manufacturing leads the way in innovation, where precision, efficiency, and reliability are not optional but essential for success. The stakes are high when designing and producing components that will traverse the skies and beyond. The industry is embracing groundbreaking technologies to meet these demands, with digital twin technology emerging as a game-changer. This cutting-edge […]

Risk Mitigation and Continuity Strategies in Aerospace Manufacturing

April 28, 2025

With supply chain shortages still a concern, proactive risk mitigation and continuity strategies are more important than ever. Even a short delay can have serious consequences, and trying to mitigate supply chain shortages on the fly can result in ineffective, expensive, and even non-compliant choices. Having supply chain risk mitigation processes in place is the […]

Supply Chain Security in Defense Electronic Manufacturing

April 25, 2025

When national security is at stake, defense electronic manufacturing partners are required to meet strict standards and regulations. Supply chain issues and component shortages have presented many challenges for product traceability. Ultimately, the best way to ensure supply chain security is to work with a certified turnkey, electronic contract manufacturer. One that keeps the project […]

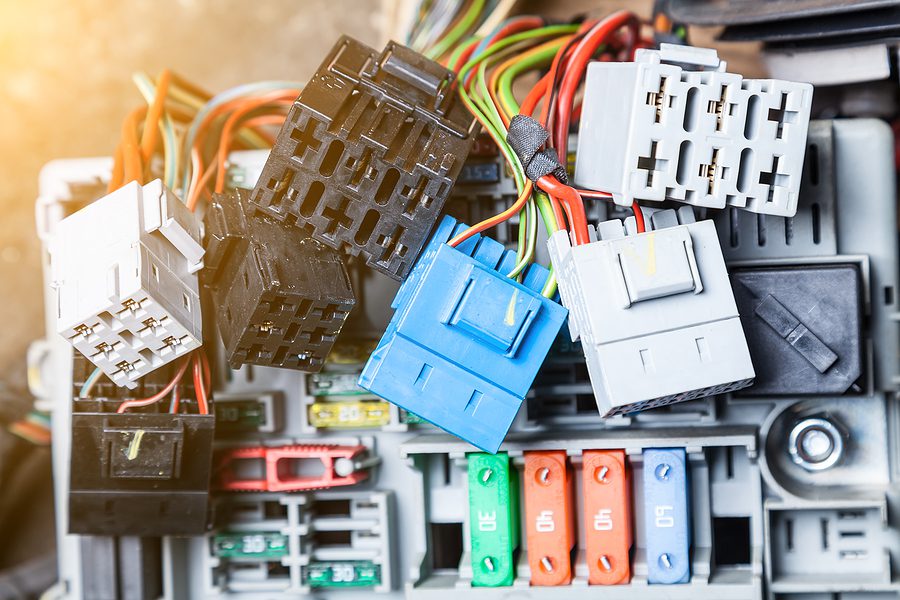

Optimal Strategies for Wire Harness Design and Assembly

April 21, 2025

Wire harnesses play a key role in various industries, acting as the central nervous system for electrical systems in everything from automobiles to aerospace equipment. Their design and assembly require meticulous attention to detail to guarantee functionality, safety, and durability. By adhering to best practices in routing, securing, labeling, and incorporating safety considerations, manufacturers can […]

Enhancing Efficiency and Quality in Box Build Processes

April 18, 2025

Box build assembly represents the critical stage where the components of your product come together in a finished, functional unit. While you may already be familiar with the intricacies of circuit board production, the challenge often lies in ensuring that the entire assembly process is efficient, timely, and consistently high in quality. Box builds encompass […]

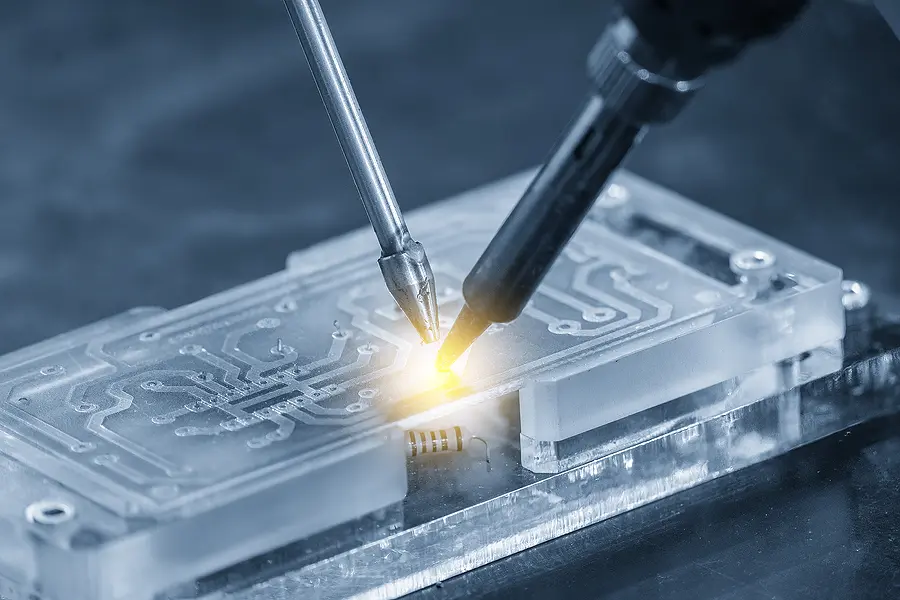

Precision Manufacturing Techniques for Aerospace Electronic Devices

April 14, 2025

The aerospace industry is known for innovation, engineering excellence, and high-level functionality. For electronic components, precision is not an option. Whether its circuit boards controlling flight systems or sensors monitoring critical equipment, manufacturing techniques must achieve exacting standards. Partnering with an experienced manufacturer like Levison Enterprises ensures that your intellectual property is protected and your […]

Innovative Aerospace Manufacturing Materials with Composites and Alloys

April 11, 2025

The aerospace industry has always been at the forefront of technological advancement, continually pushing the limits of engineering, performance, and science. Every component, from airframes to intricate onboard systems, must meet exceptionally high standards to withstand extreme environments, intense vibrations, and rapid temperature shifts. While much of the focus tends to be on the structural […]

Enhancing Usability and User Experience Through Medical Device Design

April 7, 2025

While the functionality and efficacy of a medical device is of primary importance when going through the design process, it is also important to consider the user experience. Medical devices are used to diagnose, treat, and prevent many different conditions, and as these devices are primarily used by patients, the user experience will make a […]