Blog

How to Avoid Common Pitfalls When Outsourcing PCB Assembly

November 28, 2025

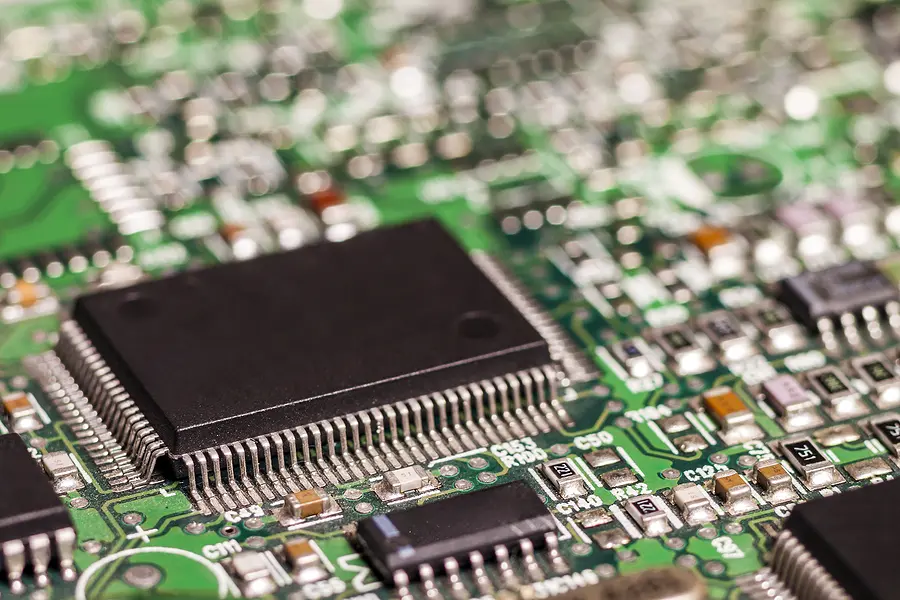

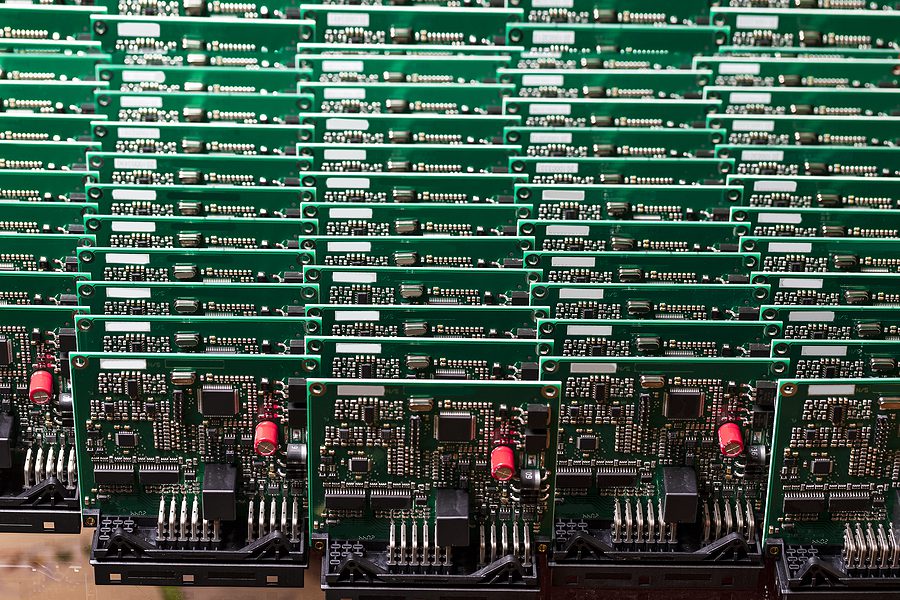

Outsourcing printed circuit board (PCB) assembly can provide original equipment manufacturers (OEMs) with the flexibility to scale production, leverage specialized processes, and bring products to market more quickly. But it can also come with challenges. Many OEMs discover too late that working with the wrong contract manufacturer introduces problems instead of solving them. A design […]

Winning the Long Game in Defense Tech with Smart Obsolescence Planning

November 24, 2025

Defense technology manufacturers face constant challenges from rapidly changing technologies and supply chain disruptions. To win the long game in defense tech, you need smart obsolescence planning. This means working with a domestic, turnkey ECM who understands the importance of anticipating risks, leveraging engineering expertise to extend legacy systems through reverse engineering, sourcing components proactively […]

Supporting Medical Teams in Developing Safe, Ready-for-Market Devices

November 21, 2025

Experienced, high-quality ECMs play an important role in working with teams through the complexities of bringing new medical devices to market. By supporting every stage of design, testing, and production, innovation goes hand in hand with safety and reliability. Dedicated engineering teams with expertise in working with medical regulations can help streamline development, optimize production, […]

Effective Supply Chain Strategies for Box Build and Cable Assembly

October 3, 2025

Imagine this: a production line is waiting on one small component to arrive. Everything else is ready—circuit boards are tested, enclosures are prepped, and workers are on standby. But that missing part is sitting in a shipping container halfway across the world. The delay halts assembly, pushes back delivery dates, and frustrates customers who were […]

Emerging Trends in Defense Electronic Manufacturing

September 29, 2025

Modern warfare is being shaped by more than troop movements or firepower. Circuits, chips, and code are shaping it, too. Defense strategies depend on how fast, smart, and reliable electronic systems are. But there’s a problem ECMs face. The technology is advancing rapidly, and staying current means more than just incremental updates to hardware. For […]

Challenges in Manufacturing Military UAVs and Drones

September 26, 2025

Unmanned aerial vehicles (UAVs) and drones have transformed the way defense operations are carried out. From real-time surveillance to target acquisition, their versatility makes them indispensable on modern battlefields. However, what appears sleek and effortless in action is actually the result of highly complex and often challenging manufacturing processes that occur behind the scenes. Building […]

Optimizing Efficiency with Lean Manufacturing Principles in Electronic Assembly

September 22, 2025

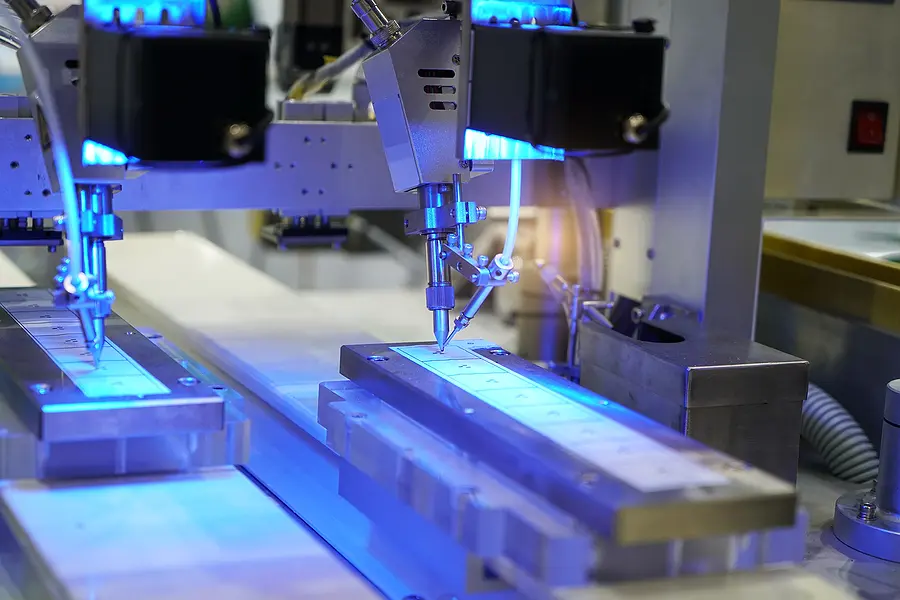

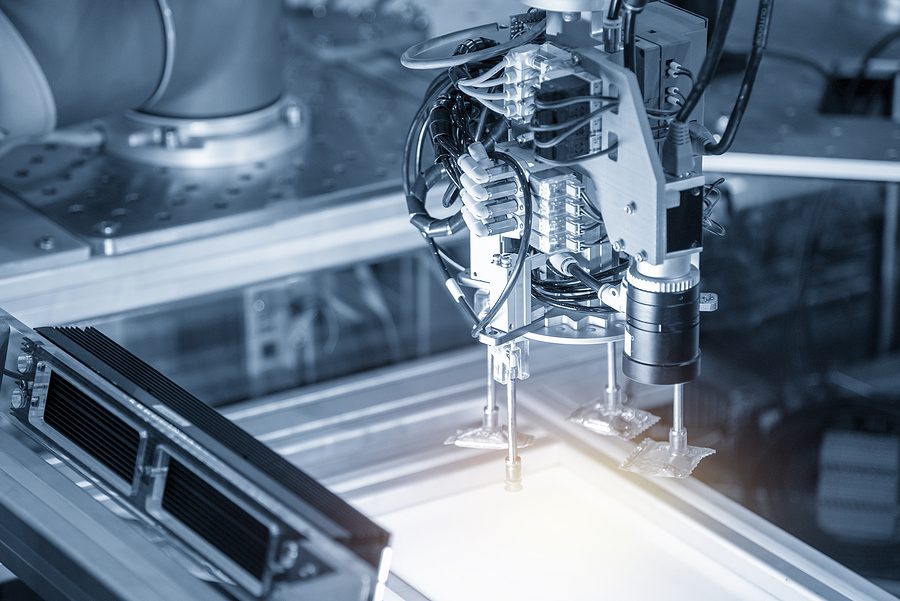

Tight deadlines, growing demand for customization, and pressure to deliver high-quality products at lower costs have made efficiency in electronic contract manufacturing a top priority. But trying to hit those marks without a clear production strategy can lead to delays, excess inventory, frustrated workers, and quality issues. Initially developed for high-volume automotive production, lean thinking […]

Innovative Technologies and Trends in Electronic Manufacturing

September 19, 2025

Electronic manufacturing has never been a static industry, where the status quo is the norm. Technology is designed to push the boundaries to see what else we can do, how far we can reach, and what we can tweak to make the good even better. In electronic contract manufacturing, technology isn’t just advancing. Technology is […]

Advancing Healthcare Through Electronic Manufacturing

September 15, 2025

Electronic devices play a critical role in advancing healthcare. The development of medical systems that rely on electronic components have allowed for devices that are more effective, efficient, and accurate than what was considered possible even as little as a decade ago. From imaging equipment to diagnostics, from patient monitoring to therapeutic devices, advancements in […]

Managing Export Control Regulations in Electronic Manufacturing

September 12, 2025

Businesses are globally connected, which is a positive thing for many manufacturers. However, connectivity brings challenges alongside opportunity, especially when it comes to adhering to export control regulations. In certain industries, such as medical devices and defense products, product traceability and meeting regulatory requirements is nothing but business as usual. When the industry itself is […]