PCBs for Aerospace Applications

Warning: Attempt to read property "ID" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 15

Warning: Attempt to read property "post_content" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 16

Warning: Attempt to read property "ID" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 15

Warning: Attempt to read property "post_content" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 16

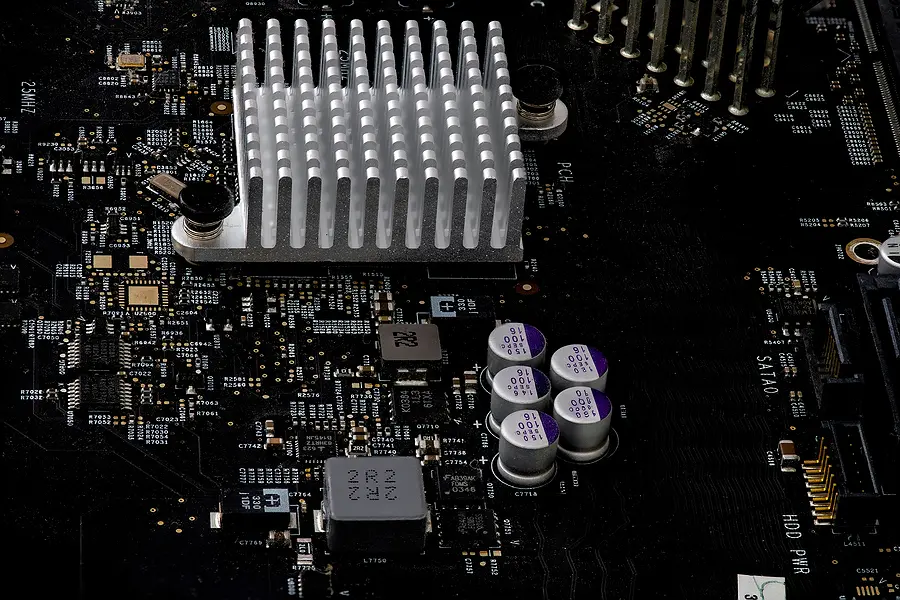

When manufacturing for the aerospace industry, precision and dependability are non-negotiable and the role of Printed Circuit Boards (PCBs) takes center stage. These crucial components serve as the backbone for electronic systems, navigating the demanding conditions of space and flight. High-reliability PCBs in aerospace applications must meet stringent standards, excelling in thermal management, vibration resistance, and radiation tolerance. This article delves into the intricate landscape of aerospace PCBs, shedding light on the specialized characteristics that elevate them above conventional counterparts, ensuring seamless performance in extreme environments.

Durability and Extreme Environments

Aerospace systems operate in some of the most challenging environments known to humankind. From the frigid temperatures of space to the intense heat generated during atmospheric re-entry, these systems are subject to extreme conditions that can wreak havoc on traditional electronic components. High-reliability PCBs designed for aerospace applications must exhibit exceptional durability to withstand temperature extremes, vibrations, and mechanical stresses.

These boards are typically constructed using specialized materials such as polyamide or Teflon, which offer superior thermal stability and resistance to mechanical stress. The choice of materials is crucial, as they directly impact the board’s ability to maintain structural integrity in extreme conditions.

Radiation Resistance

One of the most critical considerations in aerospace applications is radiation resistance. In space, cosmic radiation can significantly threaten electronic components, potentially causing malfunctions or complete failures. High-reliability PCBs are engineered with radiation-resistant materials and designs to address this challenge.

Layers of shielding, such as copper or other conductive materials, are integrated into the PCB to mitigate the effects of radiation. Additionally, special coatings protect the board’s components from ionizing radiation. These measures ensure the reliability and longevity of the electronic systems, especially crucial for satellites and space probes on extended missions.

Quality Control and Certification

Aerospace applications demand the highest level of quality control to guarantee the flawless operation of electronic systems. Rigorous testing and inspection processes are implemented throughout the manufacturing and assembly phases. Thorough scrutiny is crucial to detect and address any possible issues proactively, ensuring resolution before the final product is deployed. Compliance with industry standards and certifications is non-negotiable. These standards define the criteria for acceptable levels of quality and reliability in aerospace PCBs, ensuring that they meet or exceed the stringent requirements set forth by regulatory bodies.

Traceability and Documentation

Traceability is a critical aspect of high-reliability PCBs for aerospace applications. Each component used in the assembly must be traceable to its source, enabling manufacturers to identify and rectify any potential issues quickly. This level of traceability is a regulatory requirement and a fundamental aspect of ensuring the reliability and safety of aerospace electronic systems.

Comprehensive documentation is another critical feature of high-reliability aerospace PCBs. Someone must maintain detailed records of the manufacturing and testing processes and the materials used must be kept. This documentation not only aids in quality control but also serves as a valuable resource for troubleshooting and maintenance throughout the lifespan of the electronic system.

Advanced Manufacturing Techniques

The manufacturing processes for aerospace PCBs often incorporate advanced techniques to enhance precision and reliability. The application of automated assembly and inspection systems is instrumental in mitigating human error and upholding consistency across the entire production process. Additionally, using advanced technologies such as laser drilling and precision milling allows for the creation of intricate and compact designs that meet the space constraints of aerospace applications.

Thermal Management

Aerospace systems, especially those operating within Earth’s atmosphere, are subjected to rapid temperature fluctuations. Efficient thermal control is essential to avert overheating and guarantee the peak performance of electronic components. High-reliability PCBs for aerospace applications often feature advanced thermal management solutions, including heat sinks, thermal vias, and specialized materials with high thermal conductivity.

The Importance of Collaboration

Collaboration emerges as a vital catalyst for success in the intricate field of aerospace technology. The synergy between electronic design and aerospace manufacturing is paramount in crafting PCBs that transcend conventional limits. This collaborative effort ensures a deep comprehension of aerospace industry intricacies, enabling the design of robust PCBs that defy the challenges presented by the unforgiving realms of space and high-altitude flight.

In Conclusion

High-reliability PCBs for aerospace applications represent the pinnacle of electronic engineering, combining durability, radiation resistance, and meticulous quality control. With technological progress, the need for electronic systems resilient to the rigors of space exploration, satellite communication, and defense applications will inevitably expand. The collaboration between electronic design firms and aerospace manufacturers is pivotal in pushing the boundaries of what is possible in high-reliability PCBs, ensuring the continued success and safety of aerospace endeavors.

In navigating the complex landscape of aerospace electronics, partnering with a trusted industry expert is paramount. Levison Enterprises stands as a leader of excellence in electronic design and manufacturing, specializing in meeting the unique needs of aerospace and defense applications. With a commitment to quality control, advanced manufacturing techniques, and a deep understanding of the strict requirements of the aerospace industry, Levison Enterprises is your ideal collaborator.

Consider Levison as your strategic electronic contract manufacturing partner for developing highly reliable printed circuit boards for aerospace applications. Backed by a demonstrated history of success and a dedication to pioneering solutions, we offer unmatched expertise for highly regulated industries. Our vast experience across just about every industry equips us with innovation and knowledge necessary for a successful end product.

To explore how Levison Enterprises can elevate your aerospace electronic systems, visit our website, or contact us today for a quote on your next project.