Advanced PCB Materials for Aerospace Electronic Contract Manufacturing

In the ever-evolving aerospace electronic contract manufacturing landscape, selecting high quality materials for Printed Circuit Boards (PCBs) is paramount. These electronic systems, designed for applications ranging from space exploration to defense and satellite communication, face unique challenges including extreme temperatures, intense vibrations, and radiation exposure. This article explores the specialized materials utilized in aerospace PCBs, focusing on high-temperature laminates. Delving into the intricacies of these advanced materials reveals their crucial role in ensuring the reliability and functionality of electronic systems that need to operate in the harshest conditions.

Aerospace PCBs: Meeting Unprecedented Challenges

Aerospace electronic systems demand precision and reliability that surpasses conventional commercial applications. The environments these systems navigate are harsh and unforgiving, presenting challenges that require cutting-edge solutions. Selecting the appropriate PCB materials becomes crucial in defeating these challenges and guaranteeing the success of aerospace missions.

Specialized Materials for Aerospace PCBs

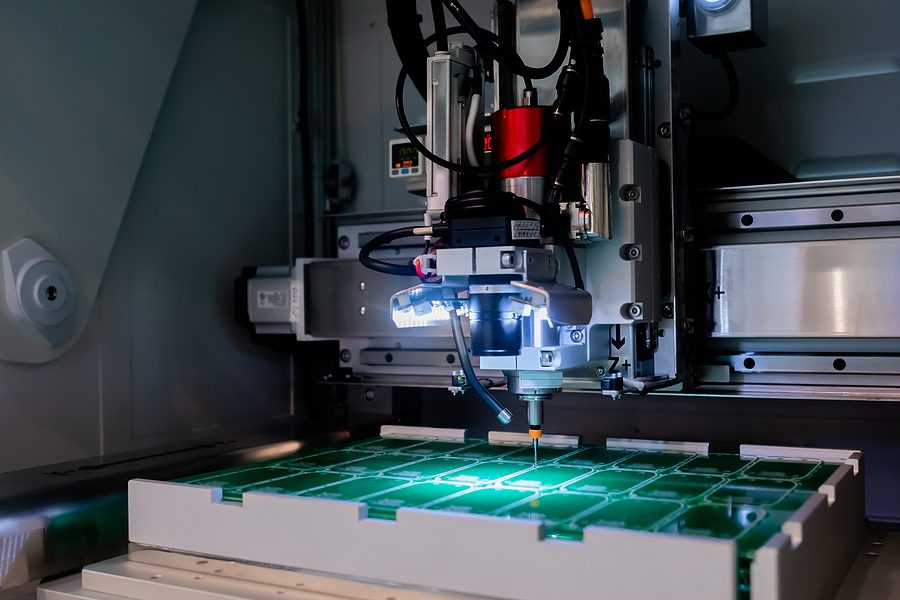

In aerospace electronic contract manufacturing, conventional PCB materials often fall short of meeting the stringent requirements imposed by extreme operating conditions. Electronic contract manufacturers use specialized materials designed explicitly for aerospace applications to address these challenges.

High-Temperature Laminates: The Backbone of Aerospace PCBs

Among the specialized materials, high-temperature laminates emerge as the backbone of aerospace PCBs. Traditional materials like FR-4, commonly used in commercial applications, may not withstand the temperature fluctuations encountered in aerospace environments. High-temperature laminates, such as polyimide and Teflon-based materials, have become the materials of choice for their exceptional thermal stability and resistance to temperature-induced degradation.

Polyimide, recognized for its outstanding thermal resistance, is a favored choice for aerospace PCBs. Its capacity to withstand temperatures surpassing those of FR-4 while maintaining structural integrity makes it well-suited for applications subject to extreme thermal conditions.

Teflon is another standout material for aerospace PCBs, offering high-temperature resistance and excellent electrical insulation properties. Its ability to maintain signal integrity in extreme conditions makes it crucial for applications where communication reliability is paramount.

Copper Clad Laminates: Balancing Conductivity and Weight

Copper is a fundamental component of PCBs, serving as a conductor and a structural element. Copper-clad laminates balance conductivity and weight in aerospace applications where weight and space considerations are critical. These laminates consist of a thin layer of copper bonded to a substrate, offering the necessary electrical properties without adding unnecessary bulk to the electronic system.

The choice of copper thickness in aerospace PCB design is also pivotal. Thicker copper layers enhance current-carrying capacity and can dissipate heat more effectively, contributing to the overall thermal management of the electronic system.

Importance of High-Temperature Laminates in Extreme Operating Conditions

In the demanding field of aerospace electronic contract manufacturing, the significance of high-temperature laminates takes center stage when confronting the challenges posed by extreme operating conditions. It’s essential to understand the critical role played by these specialized materials in maintaining structural integrity, ensuring thermal stability, and safeguarding signal integrity under the harshest environments imaginable. The importance of high-temperature laminates becomes evident as they emerge as the linchpin for electronic systems navigating the unpredictable terrains of space exploration and defense applications.

Thermal Stability: Navigating Temperature Extremes

Aerospace systems often encounter extreme temperature variations, from the freezing conditions of space to the intense heat generated during atmospheric re-entry. High-temperature laminates are crucial in maintaining PCBs’ structural and electrical integrity under these challenging conditions. They resist warping, delamination, and other thermal-induced issues that could compromise the functionality of electronic systems.

Vibration Resistance: Stability in the Face of Tremors

Launching into space or navigating the Earth’s atmosphere exposes aerospace electronic systems to intense vibrations. High-temperature laminates provide the rigidity and stability to prevent micro cracks or fractures in the PCB caused by constant vibrations. This resilience is essential for ensuring the longevity of electronic components and minimizing the risk of system failures during critical missions.

Radiation Resistance: Shielding Against Cosmic Threats

In the vast expanse of space, cosmic radiation poses a significant threat to electronic components. High-temperature laminates, especially those with additional radiation-resistant coatings, act as a shield, protecting the PCB and its components from the potentially damaging effects of ionizing radiation. This feature is particularly crucial for satellites, space probes, and other aerospace systems embarking on extended missions in outer space.

Signal Integrity: Preserving Communication in Harsh Environments

Maintaining signal integrity is paramount in aerospace applications where communication and data transmission are mission-critical. High-temperature laminates, particularly those with low dielectric constant and low loss tangents, help minimize signal attenuation and distortion. This is essential for ensuring reliable communication between components, whether in Earth’s orbit or on a distant planet.

The Future of Aerospace Electronic Contract Manufacturing

In the fast-evolving aerospace electronic contract manufacturing industry, the choice of PCB materials is a critical factor in determining the success and reliability of electronic systems. High-temperature laminates, with their exceptional thermal stability, vibration resistance, radiation resistance, and signal integrity properties, emerge as indispensable components in the construction of aerospace PCBs.

As technology advances, the demand for electronic systems capable of withstanding the extreme conditions of aerospace environments will only grow. Electronic contract manufacturers specializing in aerospace applications must remain at the forefront of innovation, continually exploring and implementing advanced materials to meet the unique challenges posed by space exploration, satellite communication, and defense applications.

Aiming for perfection, using high-temperature laminates reflects the industry’s commitment to pushing boundaries and achieving new heights in aerospace electronic contract manufacturing.

Discover the future of aerospace electronics with Levison Enterprises: Elevate your projects to new heights with our cutting-edge advanced PCB materials. Contact us now to discover boundless opportunities and redefine excellence in Aerospace Electronic Contract Manufacturing with Levison Enterprises.