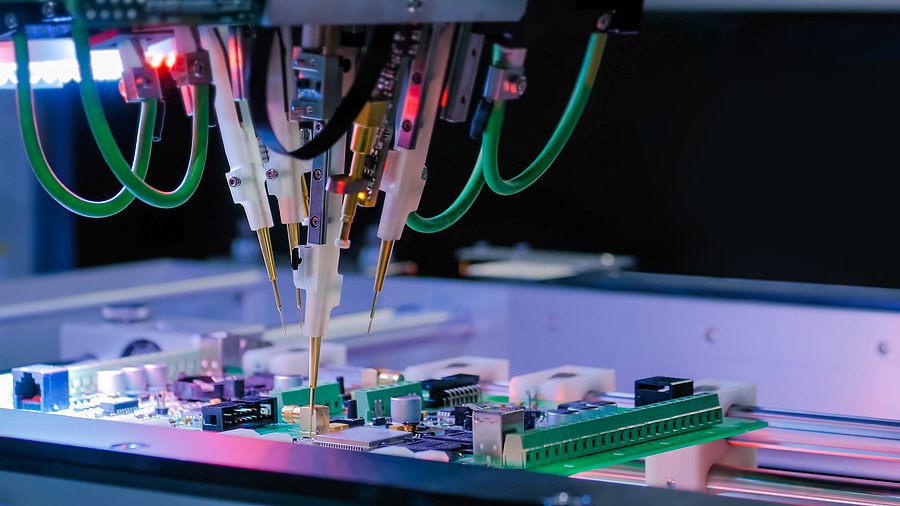

Will Your Electronic Manufacturing Project Require a Box Build Assembly?

A box build, also known as systems integration, can be anything from a simple PCBA housed in a small enclosure to a cabinet housing a complex electromechanical system. Box build assembly involves everything from start to finish in electronic manufacturing, including design, production, and construction. Box builds are cost-effective, saving both time and money. There are many industries that utilize this functional design.

Medical

The medical industry uses box build assemblies in applications relating to medical equipment and various types of clinics. They are used to create mobile diagnostic stations, ophthalmic systems, surgical robots, and obstetrics tools. Box build assemblies are also required for radiological and other medical imaging and patient monitoring equipment.

Automotive

The automotive industry must produce several smaller parts that greatly benefit from using box build assemblies. Examples of applications include headlights, batteries, windshield wipers, power door locks, and brake locks. Other systems also require this assembly type, including air conditioning, ignition, and power windows.

Military

The military uses box build assemblies to produce tactical equipment, weapon systems, system control devices, and custom testing fixtures. Like the automotive industry, the military relies on these assemblies in vehicle production, such as armed robotic vehicles, crewless aerial vehicles, and combat vehicles.

Defense

The defense industry may use custom assemblies in producing artillery, and missile, and multi-caliber individual weapon systems. The defense industry also uses box builds for avionic controls and gauges in aerial combat vehicles and utility helicopters.

Aerospace

The aerospace industry utilizes many complex electrical systems that rely on box build assemblies to facilitate the optimal performance of electrical systems. Navigation systems, cockpit instrumentation, communication systems, flight simulators, and in-flight entertainment systems all require box build assemblies.

Electronic Device

There is a broad selection of applications for box builds within the electronic industry. These can range from home security systems and data transfer devices to automation systems. In addition, many applications involve touchscreen point-of-sale systems and flat panel displays.

Agriculture

The agricultural industry uses many heavy-duty machinery and technological systems that benefit from customized assemblies. Possible applications include harvesting equipment such as threshers, water lifting equipment, and mobile spray or soil maintenance systems.

Benefits of Box Build Assemblies

A box build assembly offers many benefits when used to produce electromechanical devices than other assembly methods. Companies partnering with an experienced and knowledgeable box build provider achieve lower production costs without sacrificing control over the system design. Outsourcing assembly operations to a third party can reduce the time and money the contracting company spends on purchasing and processing material and equipment. In addition, they get an extra set of eyes on the project to ensure it proceeds as planned.

Do You Need a Box Build Assembly Partner?

By partnering with Levison Enterprises, you can save time and money on your next assembly project. We understand that each box build is unique, ranging from a simple PCB enclosure to a large cabinet full of wires, complete with electronics and pneumatics. Whether your electronic assembly requires a straightforward box build or a complex design, Levison Enterprises has the experience and expertise to successfully complete the job. Our ISO 9001 and AS9100 certifications through NSF-ISR demonstrate our quality control and auditing processes meet the highest standards. Let the experts at Levison Enterprises handle your next box build assembly needs. Contact us today to see what we can do for your next project.

Start Your Quote Now!