Your Electronic Device is Only as Good as Your ECM

Your product is only as good as your manufacturing partner. When OEMs outsource printed circuit boards (PCBs) or electronic box build assemblies, the main criteria when selecting an electronic contract manufacturer (ECM) has always boiled down to cost, quality, and delivery. However, with so many companies claiming to deliver these three key elements, it can be difficult to assess if an ECM is truly worthy of your business.

To find the right partner, it helps to understand the process. What moves a successful electronic device quickly from idea to finished product?

Design Support

When working with multiple companies’ things tend to fall through the cracks. Working with a proactive, experienced ECM who has redesigning capabilities will give you the design support you need for your PCB assembly. This support can optimize manufacturing and accelerate product development cycles. Collaborative companies are the ones that get ahead.

Industry Experience

Finding an ECM partner that understands the specific requirements associated with your industry is crucial, as not all have experience in all industries. You need a partner who understands that compliance with industry laws, regulations, guidelines, and specifications can affect each phase of the manufacturing process. You also want to ensure an ECM can handle the project and meet the stringent industry regulations you are under.

DFM

DFM (Design for Manufacturing) analysis requires component design, thorough testing, and access to the latest prototyping technologies and analytical tools. The goal of a DFM analysis is to find a product design involving the least complexity in the manufacturing of different components. Modern electronics are complex, but a DFM analysis can help find solutions for trimming excess material spending and producing more streamlined products. A DFM analysis aims to reduce the overall costs for producing all parts of a product or assembly.

Domestic ECM

A domestic, turnkey ECM means IP protection, no language barriers, no delays in importing, the ability to catch errors early in the process, and your product gets to market quickly. In addition, domestic ECMs are committed to quality. In-house engineers can find errors early, saving you time and money. Having engineers on-site optimizes the process from beginning to end. Using an overseas ECM may require spending your own resources on quality assurance after delivery, which can cost a lot more. If errors are detected at that point, it can also increase your timeline substantially.

Vetted Supply Chain

Having a vetted supply chain at your disposal is vital to ensuring a quality product. If you use non-vetted suppliers, you risk parts being incorporated into your product that are low quality and possibly counterfeit. Partnering with an ECM who has a network of vetted suppliers will help with parts procurement and ensure all parts have been tracked through an established supply-chain management process. A vetted supply network means you can feel confident the parts are high-quality and legitimate.

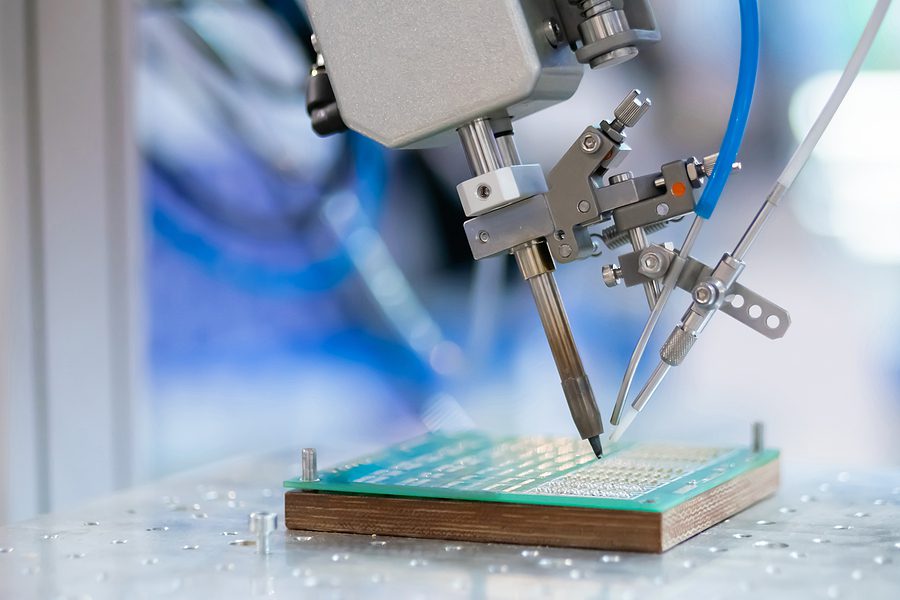

Certifications and Equipment

There are countless benefits to working with an electronic manufacturing service with quality certifications and processes in place. Quality certifications show that your ECM is continually working to improve themselves and their systems. Improved systems and processes may lead to better product quality and manufacturing efficiency.

One of the main ways companies can save money with an ECM is through the use of state-of-the-art equipment and quality processes. Technology evolves quickly, making it almost impossible for smaller businesses to stock their product floors with up-to-date equipment. Leveraging their equipment and capabilities without having to worry about keeping pace with production technology is a huge plus.

Turnkey

Choosing a domestic, turnkey ECM means all services can be handled by one partner, under one roof. A partner who will be able to communicate easily with you throughout the entire process will keep things on track. There are several benefits to outsourcing your project to a domestic turnkey ECM, from cost savings to streamlined communication. Turnkey manufacturing allows for faster production times, better outstanding service and savings, and higher-quality work from experienced engineers and designers.

Fulfillment Services

Getting your product to your customers can be challenging when it is ready to hit the shelves. Packaging your new product may require additional labeling to make it easier for a retailer or distributor to sell. A turnkey ECM partner can help ease the burdens associated with packaging and fulfillment services. They have you covered by individual packaging in a box, multiples in a bag, or bulk packaging. Your turnkey manufacturer should be able to handle all your packaging and fulfillment needs from beginning to end.

Why Choose Levison Enterprises?

As you can see, the criteria listed above will positively impact your product through the manufacturing process, so it’s essential to choose your electronic contract manufacturer wisely.

At Levison Enterprises, we provide expert design and engineering support, robust quality assurance measures, and state-of-the-art technology. We are a full-service design to build manufacturer with redesigning and reverse engineering capabilities, taking your ideas or designs, and turning them into a finished quality product.

Don’t trust your product to just anyone. Levison Enterprises is a manufacturing partner who will be as invested in your project just as much as you are. We can help you build a better product. Contact us today to learn more about our capabilities.

Start Your Quote Now!