What to Look for in a Rigid-Flex PCB Electronic Manufacturing Partner

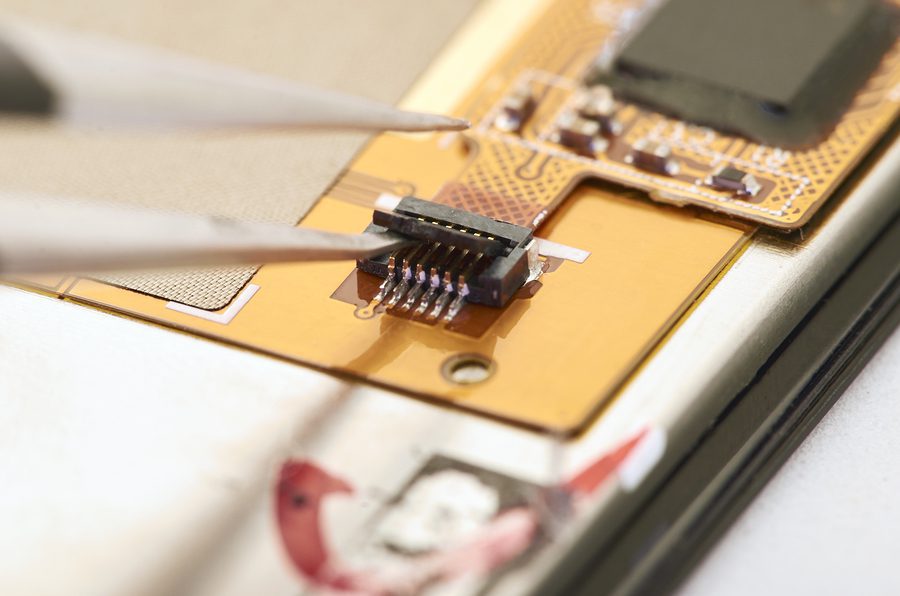

Rigid-flex printed circuit board components represent the next evolution of standard printed circuit boards. Combining the best of both worlds, rigid-flex printed circuit boards deliver advantages in design, cost efficiency, and resiliency. Overall, they allow design to be function-first, giving your electronic manufacturing project the design freedom it needs.

Why Rigid-Flex?

Each type of printed circuit board brings their own pros and cons to the drawing board. Rigid PCBs allow for greater routing density, and represent a cheaper alternative than flex PCBs. On the flip side, flex PCBs offer greater overall flexibility, but sacrifice routing. Flexible printed circuit boards are also more costly to produce.

Combining the two types into a rigid-flex PCB brings each board’s strength to your project. You’ll get more routing capability at a cheaper cost while also offering necessary circuit density in a lightweight design.

While including flex PCB components into your overall PCB design may result in an increased cost, that extra spending is worth the overall savings in the long run. The pliability they bring to your project can save you money down the road in terms of design and efficiency to the end user.

Advantages of Rigid-Flex PCBs

While many projects can benefit from having the option of a rigid-flex PCB onboard, there are other projects in which they are a necessity.

Rigid-flex PCBs are imperative if your project is going to be exposed to a high-vibration or high-shock environment. The rigid-flex PCB configuration delivers in these environments where lesser rigid-only PCB components with traditional connectors would fail much sooner. Burying the flexible circuits inside rigid boards also helps keep things held together under even the most extreme situations.

Rigid-flex boards are lighter than traditional rigid PCBs. This is huge for designers because you can still maintain circuit density without worrying about increasing the weight of your board and end product. Smaller rigid-flex PCBs can see an increased cost over traditional rigid boards, but if your configuration expands beyond four boards, your project will see direct savings when using a rigid-flex design.

Finding the Right Manufacturer

Rigid printed circuit boards have been a part of electronic contract manufacturing for so long, many designers and manufacturers default to using them without a second thought. When you elect to pursue rigid-flex PCBs in your project, however, finding the right team to bring your project to life becomes imperative. Rigid PCBs are easy, but as soon as you decide to include rigid-flex printed circuit boards, you are literally and figuratively expanding from the 2-dimensional realm to 3-D. Bringing your project to life requires a manufacturing partner and design team you can trust with your files who has the knowledge and experience you need.

Levison Enterprises is the right partner for your next project. With decades of experience in electronic contract manufacturing, we are a turnkey service that takes you from vision to design to final product, with the collaboration necessary along the way to make it a success. Our team of in house engineers are there to fabricate and troubleshoot early in prototyping to ensure your finished product works the way it should every time. Our quality control and certifications show our commitment to manufacturing top-notch PCBs with your end user in mind.

For more information about how a rigid-flex PCB set-up can benefit your future projects, contact our team today.

Start Your Quote Now!