What Is Medical Device Manufacturing?

As Baby Boomers age, and technology advances the ways in which consumers interact with medical care, medical device manufacturing is seeing new growth. Demand for new and improved medical devices continues to grow, meaning more demand for medical device manufacturers. When demand gets high and changes are happening quickly, contract manufacturing always has an important role to play. This will be and is true especially in medical device manufacturing.

What Is Medical Device Contract Manufacturing?

To start, let’s shelve the term “medical device” and focus for a minute on contract manufacturing. A contract manufacturer, like Levison Enterprises, can design, produce, and ship whole products, single parts, and everything in between for original equipment manufacturers. The parts or products created by contract manufacturers might later go straight to the marketplace, or be used in products that will be assembled by another manufacturer.

So, back to the medical devices. When you imagine a medical device, it could be just about anything from a $5 electric toothbrush to a highly-sophisticated on-site imaging system that takes up a whole room in a hospital. The technical definition of a medical device in the United States includes regulation by the Food and Drug Administration (FDA), which states that a medical device is “an instrument, apparatus, implement, machine, contrivance, implant, in vitro reagent, or other similar or related article, including a component part or accessory.” The definition of medical devices also includes pharmaceuticals and supplements that have a goal of prevention, cure, diagnosis or otherwise impacting the human or animal body.

Medical devices, therefore, are everywhere. But, they are most commonly found in medical facilities, long-term care facilities, labs, and in home health settings.

What To Look For In An Experienced Medical Device Contract Manufacturer

Having an on-site engineering team allow medical device contract manufacturers to test and rework design changes and manufacturing processes. Quality medical device manufacturers will also have other advantages in place to ensure you get an excellent and reliable medical device.

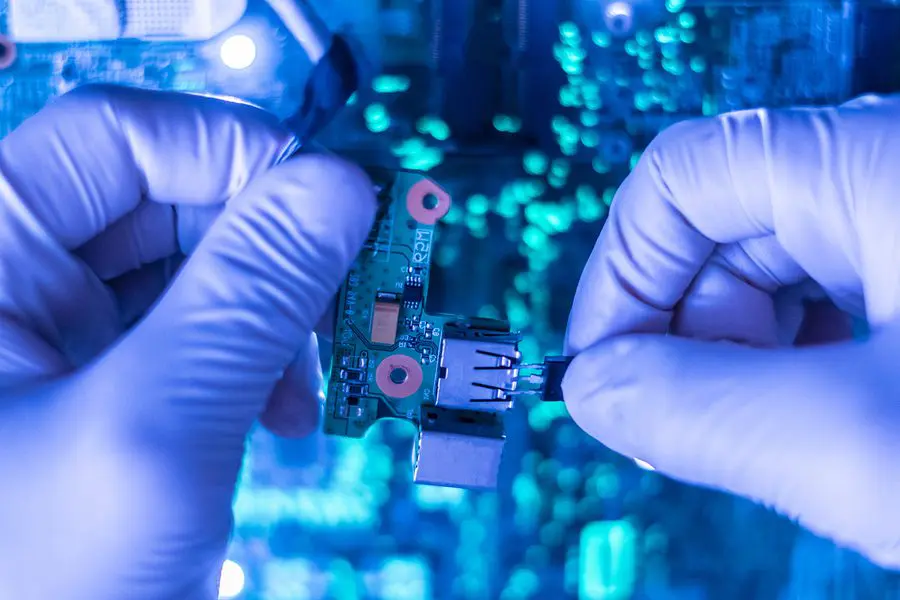

Make sure your medical device manufacturer has standards in place to be sure your devices will be produced without contaminants. This can include anything from cleanliness processes to bug and rodent control plans. Cleanliness is a key factor in medical device assembly.

A reputable medical device manufacturer will also be prepared to meet all regulatory requirements for medical device manufacturing. In addition to producing contaminant free devices, these contract manufacturers should also provide quality control standards, custom packaging, and be able to validate their services.

Levison Enterprises is your Medical Device Contract Manufacturer

For years, Levison Enterprises has built its work on the highest quality standards available. In the medical device manufacturing field, there can be no characteristic of greater importance. Levison Enterprises knows how to meet the highest quality standards while meeting your deadlines and other priorities.

Levison Enterprises offers on-site facilities, extensive expertise, and a team that is eager to create the best product or part to meet your needs.

Contact Levison Enterprises to for ISO 13485 certified medical device manufacturing design, production, and shipping.