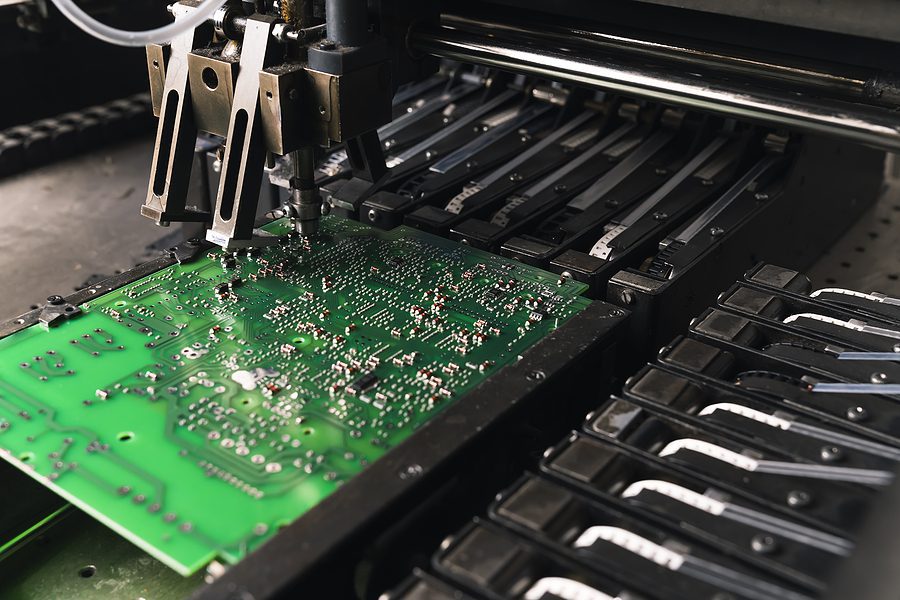

What Factors are Considered When Quoting PCBA?

PCB quotes are influenced by a number of factors. When you are first meeting with an ECM to outsource your PCBA, it may be confusing to decipher how the ECM arrived at a particular quote. With the right information about how the factors impact the cost of your project, you can plan and budget for your PCBA project effectively.

Board size

A panel is required to make a PCB. The size of the PCB, and therefore the size of the panel, is a key consideration for determining cost. This doesn’t always mean that the bigger the board, the higher the price, as other factors are crucial to determine cost, but size does matter.

Run Size

Many manufacturers have a minimum run size for an order. Quantity is very important when determining the quote for a PCBA. As the quantity increases, the cost per board will fall. Often, you will get discounts when requesting bigger orders, even if you request smaller quantities over time.

Layer Count

While single-sided and double-sided PCBs cost nearly the same to manufacture, adding additional layers will add to the material, manufacturing, and overall cost of the PCBA. A four-layer PCB will be twice the cost of a two layer, but adding more layers will not increase the cost as drastically. In general, the more layers necessary, the higher your quote will be.

Drill Size and Count

The smaller the hole size and the greater the amount of holes necessary, the higher your overall costs will be. The manufacturing process will need to be altered for smaller hole sizes and higher hole counts, which will reduce the number of panels that can be drilled simultaneously. Increasing the labor will increase the cost of your project.

Materials

There are several types of materials that can be used in PCB fabrication, and different types of materials and thicknesses can have a big impact on cost. The most popular material for PCBA is FR-4, which is made of fiberglass and other materials woven together with an epoxy resin to create a fire-resistant composite. When pricing your PCB, the material your project requires can make a big difference in your quote.

Space

Many PCBs require small components, and the spacing between the copper features on the board will be reduced to allow for more components. More room on the board means lower costs. If the spacing is small, costs will likely rise.

Lamination Process

If the lamination process isn’t standard, the costs will be increased. Multi-layer PCBs that involve laminating with a different material type will often drive up the costs. If your board requires a non-standard lamination, expect to see that reflected in the quote.

Testing Requirements

Testing is very important to the PCBA process, but testing does take time and expertise. While there are several standard tests that are typically carried out during the manufacturing process, requesting additional testing will likely bring an increased cost.

Most PCB manufacturers will have similar overhead expenses, so pricing is often similar for comparable projects between manufacturers. However, when looking for an ECM for PCBA, cost should not be the only factor. Although you want to ensure that you are getting a fair quote for your project, it is important to choose an ECM who has experience in a wide range of industries and the capabilities necessary to complete your project successfully. A domestic, turnkey partner who offers design assistance and in-house engineers will prove to be a valuable asset throughout your project. To learn more about how Levison Enterprises can help you build a better device, contact us for a quote today.

Start Your Quote Now!