The Top 5 Reasons Mechanical Engineers Should Reconsider Their ECM

Sometimes we find the best quick fix, and then stay because we know it’s currently working. But what if there is something better out there for you? Working with the right electronic contract manufacturer can mean the difference between your project being a huge success or a big flop. While outsourcing is a way of life for electronic manufacturers, working with the wrong ECM is at the root of many problems. Here are some ideas to help you figure out if you’re really getting the best deal from your current ECM.

1. Unable to Scale Up or Do Low Volume Runs

A big fear of a small to low-volume company is the fear it will not be able to find an electronic contract manufacturer willing to do small production runs. It is the process that should matter, not the size. A quality ECM will be willing to manufacture any number you need at the best possible price. They should have a proven supply chain to guarantee high quality at a low cost. On the flip side, your ECM should have the infrastructure in place if you need to scale up production and require large-scale assembly.

2. No Testing In-House

Working with an ECM that does not have in-house testing can put your business at a big disadvantage. When testing is done on-site, the engineering team can troubleshoot any issues right away while sticking to deadlines. This should be done throughout the manufacturing process to ensure performance, function, and reliability. Testing performed off site can take up valuable time and lead to manufacturing delays. This will increase production timelines and cost more money. In short, an ECM with in-house testing can save you valuable time and money.

3. No Shipping Options

Shipping can often be an overlooked element of your relationship with your ECM. Your workflow depends on the time it takes for a shipment to arrive and the condition your product arrives in. You need an ECM that can get your assemblies where they need to be when they need to be there and in top condition. They need to not only be able to quickly ship domestically, but internationally as well. This should also include overseas shipping. Work with an ECM that can provide reliable transit at a reasonable cost.

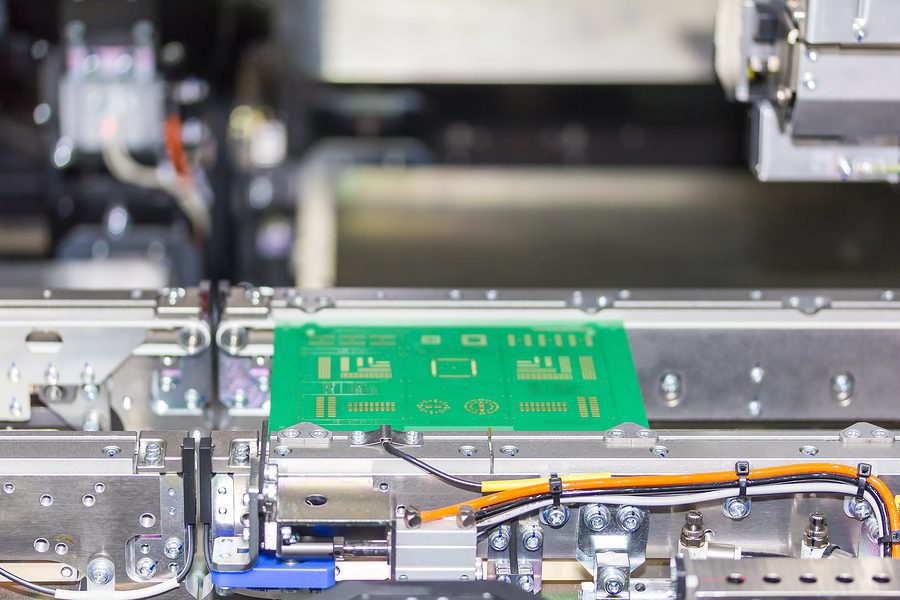

4. Can Only Do PCB Subassembly

You might be wasting time and money If your electronic contract manufacturer can only do your PCB assembly. When your ECM cannot complete your total assembly, it drives up shipping costs as you continue sending your product on for further manufacturing. There is also an increased risk for errors. Quality control can fall between the cracks as the chain of custody is transferred. You need a one-stop-shop ECM that can provide turnkey electronics assembly.

5. No ENG In-House

The number one reason to reconsider from your ECM is if they have no in-house engineering. When something goes wrong with your PCB assembly project, you need someone who truly knows your project to respond right away. In-house engineers at your ECM will be with your project every step of the way from development to final testing. They will know your project inside and out, and can respond to issues that arise immediately with reliability and expertise. This will decrease your timeline and improve the overall return on investment of your project.

With the right electronic contract manufacturing partner, you eliminate a lot of the pitfalls that can torpedo your product and send you back to the drawing board. Levison Enterprises takes the stress out of the production process to provide you frustration-free manufacturing. Let us take care of the entire process including PCB fabrication, component procurement, assembly, testing, and shipping. Contact Levison Enterprises today for a free quote on your next project.