Seamlessly Outsource Your PCB Design to a Box Build Manufacturer

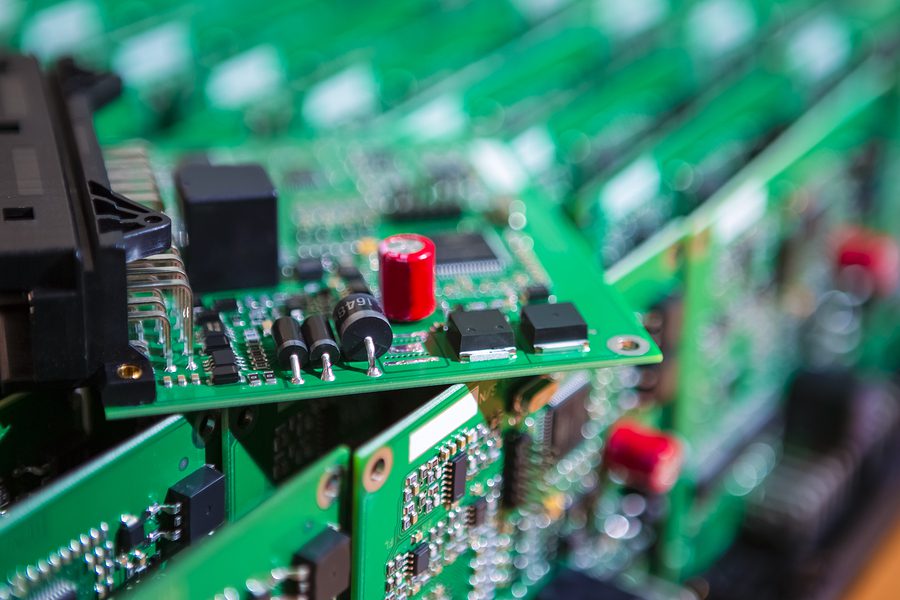

Many electronics companies require a contract manufacturer for not only their printed circuit board assembly but also the final assembly of their innovative products. In some cases a box build assembly can be the perfect solution. A box build is a systems integration that includes all electromechanical assembly housed in an enclosure. They can be used in a wide array of applications, and can range from small and simple to large and complicated. A box build can be the perfect turnkey solution for all your outsourcing needs. Once you have decided this is the route for your next project, there are some simple steps to seamlessly transition your design to a box build manufacturer.

What Do I Need For A Box Build Assembly?

There are some basics you need right off the bat to make sure everything goes according to plan with your box build assembly. First and foremost, your manufacturing partner will need a well put together technical data package including drawings and a Bill of Materials (BOM). The drawings should be clear and professionally done (if they are not, talk to your ECM about their design capabilities) and the BOM should include all of the components needed for the build. It should also clearly state where the materials will come from, what you will provide, and what is to come from your ECM. You will want to be sure your assembler has a vetted supplier network so you know quality parts will be used on your project. Also find out in advance if your ECM will assemble everything in house or if they are going to sub-contract any part of your project. These factors can affect the overall cost.

Drawings and Assembly

Your ECM will need to know exactly what you expect your finished product to look like. You should supply drawings with tolerance and clearances clearly labeled. This is the best way to get exactly what you need instead up leaving it up for someone to guess. If the drawings are incomplete, you can supply a demo prototype or be sure you have a partner with in-house engineers who can help make sure your design is complete.

Your manufacturing partner also needs to know other details about the project. Be sure to list any specific type of technology that needs to be used to determine the build method. Your ECM will also need detailed diagrams of the electrical circuits. Be sure to include the exact size and weight the finished product needs to be. This needs to be kept in mind throughout the assembly process, and will ultimately affect shipping and storage.

It is also a big bonus to contract with an ECM that has the ability to prototype in-house. This allows for design and function testing on the spot to determine if changes need to be made before assembly begins.

Outsourcing your box build means working closely with a company that you can trust with you product and that you will form a close working relationship with. Levison Enterprises offers Nimble predictive flash storage technology, subassembly or full assembly, testing in house, and all other features mentioned above. We have the resources and skills to design and manufacture a wide range of custom box build electronic assemblies for any industry. Contact Levison today to discuss innovative solutions for your box build.