Save Money Without Sacrificing Quality on Your Next PCB Assembly Through an Electronic Manufacturer

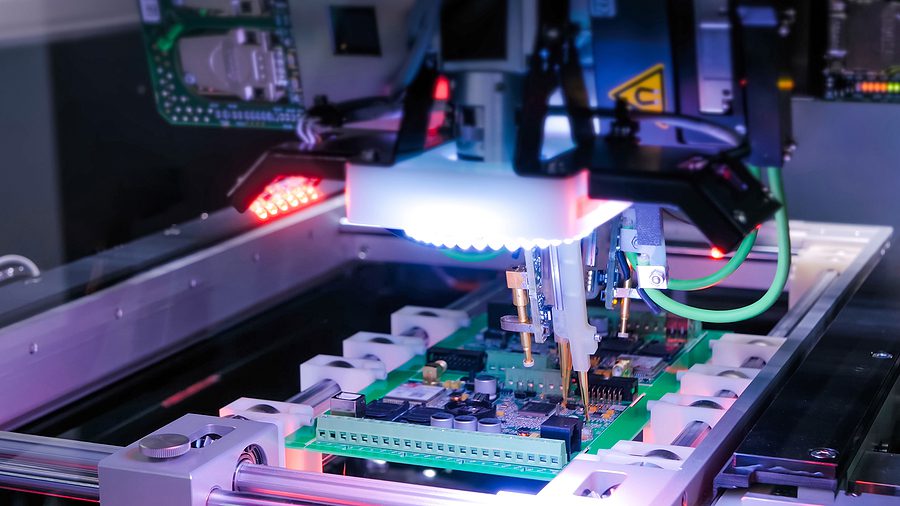

Cheap and high-quality are not typically easily interchangeable terms. This is especially true when it comes to hiring an electronic manufacturer for PCB assembly. There are a lot of moving parts that must perfectly come together to create top-notch printed circuit boards. However, there are ways to cut costs without sacrificing the quality of your project.

Many money-saving strategies come into play early on in the PCB development process. Choosing a smart design, along with a great manufacturing partner, can help you get more bang for your buck.

Choose SMT On One Side of The Board

The more complicated a board gets, the higher the price. Keeping all of your SMT components on one side of the board will help control costs. Each side of a board must go through the manufacturing process. So, keeping components on only one side eliminates the cost of a second run.

The same goes for adding extra layers. Each additional layer added to your PCB could drive up your budget by 20 to 30 percent.

Choose Components That Can Be Easily Substituted

Choosing components that can be easily substituted is a way to save you money in the long run. If you need to do a last-minute part swap due to circumstances like parts obsolescence, your smart component choice can save you the price of a complete redesign.

Using components that fit a standard footprint will make it easy to substitute quickly and efficiently. Also be sure to check end-of-life forecasts for any component you intend to use.

Don’t Go with The Smallest Components Available

Small components require much more time to properly pick and place. This means using small parts will increase your manufacturing cost. Avoid this by choosing components larger than 0402 that are more budget-friendly for assembly.

Choose Industry Standard Materials and Spacing

Think standardization if you are looking to save money on your PCB assembly. Avoid unusual shapes, sizes, and materials. The more labor needed to create the shape of a board, the more it will cost. This includes cutouts, slots, and contours.

In addition, using standard parts and components can speed up manufacturing. This, along with reducing the scale of production, can lead to cost savings.

The type of materials used to build your board will dictate the cost, too. Straying from common materials, like epoxy resins, drives up the price.

On-Site Engineers

An ECM that has engineering on staff will be able to look over your PCB plan and see where things can be streamlined. They will be able to build exactly what you need on time and on budget.

In-house engineers will also be there to troubleshoot during the manufacturing process. This means problems with your project will be solved immediately. Detecting and correcting issues with your PCB assembly early avoids a production slow-down that could inflate the price.

Getting the PCBs you need without breaking the bank starts with finding the right electronic contract manufacturer to partner with in order to create your printed circuit boards on budget. Levison Enterprises is that company. We can look over your PCB order to see where you can save money while maintaining the highest quality product at a fair price.

Let Levison Enterprises be your electronic contract manufacturer. Contact us today for a quote to get started on your design.

Start Your Quote Now!