Proactive Steps to Manage Electronic Manufacturing Parts Obsolescence

Parts obsolescence can be a problem in the electronic manufacturing industry. Obsolescence can be one of the greatest challenges for manufacturers. When an OCM decides to cease production of a component, that component is considered to be approaching obsolescence. This means that an OEM must decide whether to discontinue the product, find a new supplier, redesign the product, or put their obsolescence management system into action and negotiate with the supplier to complete the manufacture of their product.

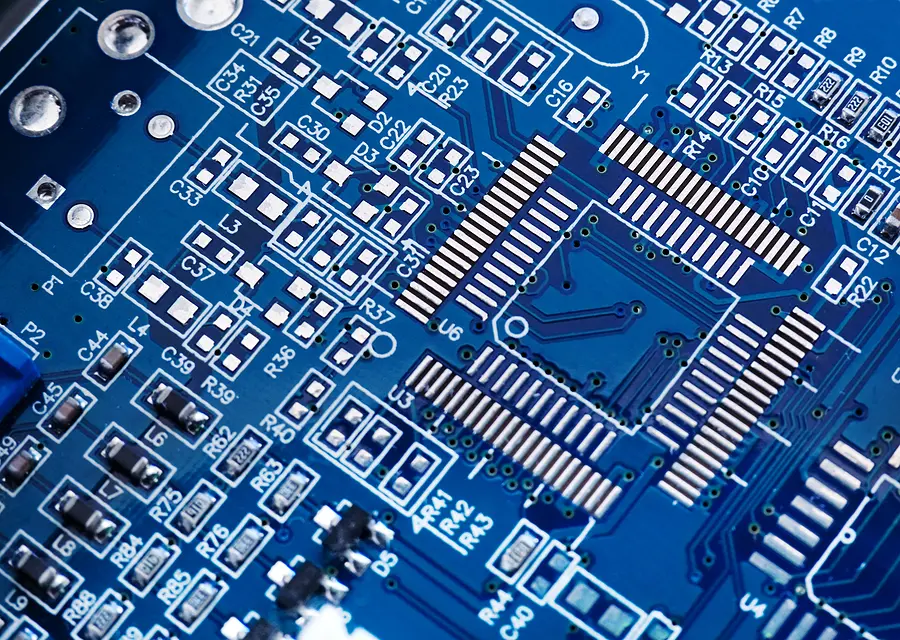

Proactive Obsolescence Management System for PCB Assembly

A proactive obsolescence management system can mean the difference between having to discontinue a product and being able to keep the current product viable and in market. Many companies outsource their PCB manufacturing and assembly. When choosing to outsource PCB assembly, look for a company who has an obsolescence management system in place. Having everything handled by a proactive partner reduces the risk of poor communication and ensures that the PCB assembly process stays on track.

Life Cycle Analysis

To help manage obsolescence, a vendor should offer life cycle analysis. A life cycle analysis program assesses a component from the beginning to the end of its predicted life. Before you begin your project, you can ask your ECM to proactively look for parts that will need to be replaced and they can suggest alternative options or components.

Good communication between ECM and their suppliers

If your ECM and vetted suppliers don’t have good communication, you may not know that you have a part nearing the end of its life cycle. Talk to your ECM about their relationship with their suppliers. Many suppliers offer a chance to subscribe to notifications about products. Having a vetted supplier is crucial to a good obsolescence management plan.

Lifetime Buy Options

Many good suppliers offer this service. If a component is crucial to your design, your ECM can make a final bulk purchase before obsolescence. Lifetime buys will give you a chance to stock up if you are making a product that cannot easily be redesigned. ECMs with trusted and vetted suppliers have a better chance at being notified of parts that may be approaching obsolescence. Once you have the end-of-life notice, your ECM can estimate how many parts you will need in the future and buy as many as they can.

Reverse Engineering

Engineers on-site are so beneficial to your build in terms of parts obsolescence management. An experienced team of engineers can help by choosing components for your project that have more predictable life cycles. This is a proactive step to mitigate the potential of your components becoming obsolete. Addressing obsolete components by reverse engineering your build and streamlining your design can save you time and money verses starting the whole thing all over again. On-site engineers can determine work-arounds to keep your project on schedule by offering alternative solutions to the parts you can’t get much longer.

Technology advances quickly, and no matter what you do there is always a risk of components becoming obsolete. Outsourcing your project to an experienced electronic contract manufacturer with in-house engineers and an obsolescence management plan already in place can make a big impact on your entire project.

Working with the right company can make dealing with product obsolescence a minor issue, rather than one that threatens the life cycle of your PCB. Contact Levison Enterprises to talk about your next build. We have the right systems and solutions in place to keep your products on the market and your business going strong.

Start Your Quote Now!