Is SMT Right for Your Next Device?

Are you wondering if surface mount technology (SMT) is well-suited for your next device? The industry standard for printed circuit boards (PCBs) has been through-hole circuits for many years. This method is relatively simple to implement but becomes time-consuming on a mass scale.

PCBs made by through-hole circuits involves drilling holes into the boards, mounting components on one side of the board, then threading the leads through the appropriate holes.

However, as the demand for new technology has risen, the need for automating this process has become apparent.

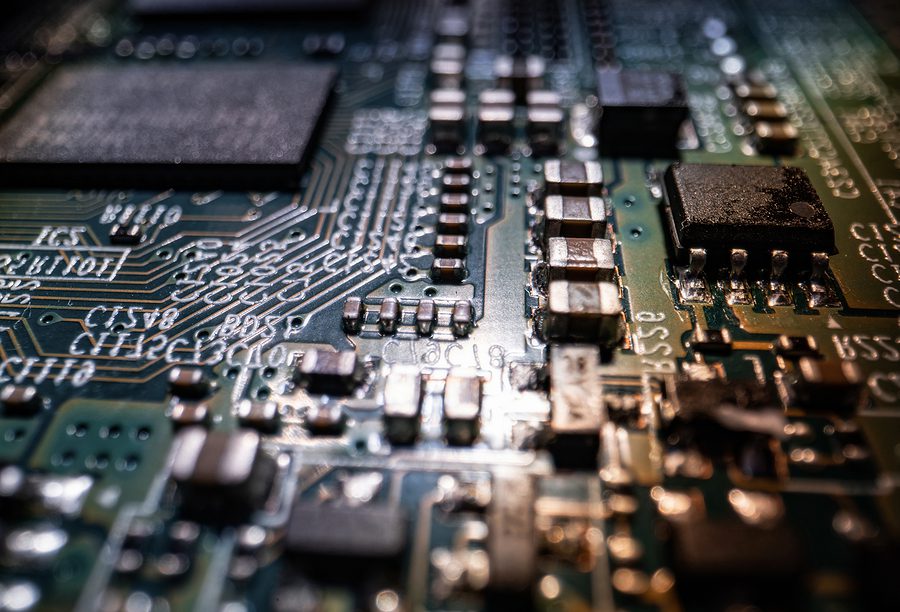

Enter surface-mount technology, also called SMT — the solution manufacturers were looking for. SMT has many benefits, like higher circuit speeds, customized soldering options, and vibration resistance.

Easier Assembly Saves Time

With SMT, fewer holes need to be drilled, saving time. Fewer holes also means better performance due to a smaller loop area. With surface-mount technology, you eliminate an entire step in the manufacturing and assembly process.

Since you don’t have to connect through holes by utilizing SMT, the assembly process will be quicker — boards become easier to design, assembly by the manufacturer goes faster, and products get to market faster.

An easy and efficient assembly process alleviates the number of potential mistakes in producing printed circuit boards.

Lower Cost

SMT offers a lower initial setup cost, especially for smaller printed circuit boards and manageable assembly processes. By utilizing SMT, companies can reduce PCB assembly prices by taking advantage of increased component density, smaller board sizes, and automated assembly. Partnering with an experienced electronic contract manufacturer further enhances cost savings through their expertise, specialized equipment, and efficient resource allocation, making SMT an attractive choice for companies seeking affordable PCB assembly solutions.

More Compact Devices and Increased Design Flexibility

One of surface-mount technology’s most significant benefits is its support for more compact devices and increased design flexibility. This is because the higher density of the board allows the PCB to take up less space while still providing the same capabilities as a traditional printed circuit board. As electronic devices get smaller and the demand for these smaller devices increases, PCBs must also get smaller. Fortunately surface-mount technology enables this.

Implementing SMT methods to your printed circuit board manufacturing process will lead to more flexibility in design and lighter products. Creating a more lightweight product can expand the possibilities for innovation, reduce shipping costs, and limit the power required to charge and use the device.

You Can Use Both Sides of the Board

Because SMT allows effective use of both sides of the PCB, you can maximize the available real estate, allowing for a greater number of components to be mounted. This enables the creation of more complex and feature-rich electronic designs within a compact form factor. Additionally, using both sides of the PCB with SMT offers improved thermal management as components can be distributed on both sides, facilitating better heat dissipation. It also allows for optimized signal routing, reducing trace lengths and improving signal integrity. Overall, the ability to utilize both sides of a PCB with SMT results in increased design flexibility, higher component density, enhanced functionality, improved thermal performance, and better signal integrity, making it a valuable approach in electronic design and manufacturing.

Start Your Quote Now!Is SMT Right for Your Device?

Surface Mount Technology (SMT) helps reduce manufacturing costs and increase efficiency, making it possible to build highly complex electronic circuits in smaller assemblies with automated methods. Once you understand SMT and its benefits, it makes it much easier to determine if it suits your project. There are many reasons to use Surface Mount Technology for your electronic device. Levison Enterprises can help you determine if SMT is right for your project. Contact us today for answers to all your printed circuit board assembly questions.