Is it Really Worth it to Outsource Your PCB Assembly?

The number of manufacturers realizing the benefits of outsourcing PCBA versus building an in-house process continues to increase, and for good reason.

If you are considering whether it is worth it to outsource your PCB assembly, the answer is a resounding YES. When you factor the cost of everything you get, you save both time and money by outsourcing your PCB assembly to a domestic, experienced turnkey shop. On top of the cost alone, you are also getting a team of experts to help ensure your project is a success.

Lower Investment

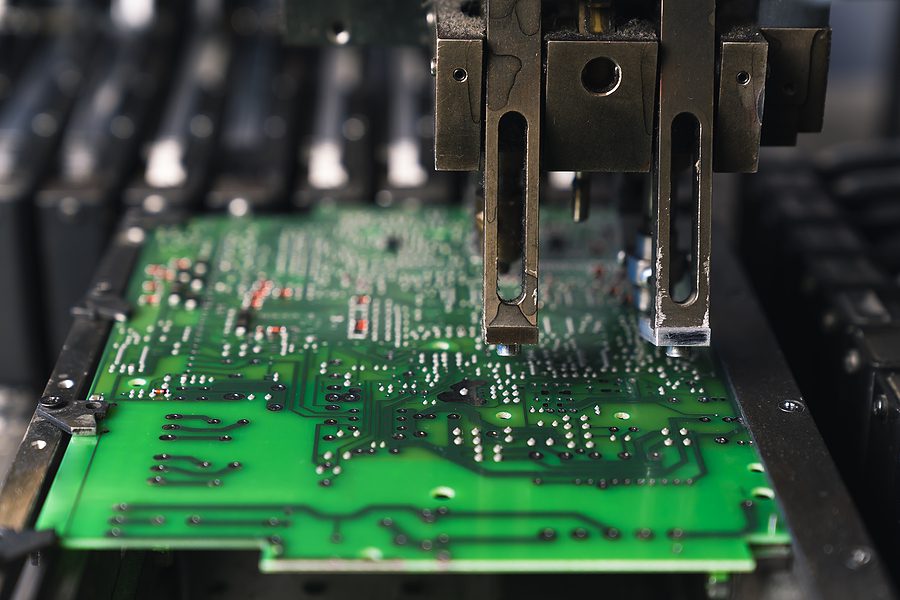

Purchasing surface mount and quality inspection machines is a massive up-front investment, as is the cost of getting certified to manufacture PCBs for specialty industry projects. You will also need to hire new employees, so you must also factor the costs of their annual salaries, health insurance, and retirement packages to the equation.

With outsourced PCB assembly, you don’t have to worry about any of that.

Savings on Facilities

Renting or leasing warehouse space can quickly drain your finances, especially if there are property taxes to pay. With outsourcing, your electronics vendor can hold your parts in-house for you, so you don’t have to find space to hold all that inventory. Your PCB manufacturer acquires the financial responsibility until the parts are shipped out.

This cost reduction provides you the opportunity to invest funds elsewhere, like marketing, R&D, or wherever else they’re needed.

Cost Efficiency

Establishing an infrastructure and operation takes years to build. Your electronic manufacturing service provider has already done just that, so why spend years trying to build your own when there is a much easier way?

A PCB fabrication expert already understands the inventory management that affect cost efficiency, such as:

- Short part lifecycles

- Price fluctuations

- Design changes

If you are a startup with little capital, it’s much easier to enlist experienced and well-managed circuit board assembly services instead of trying to consolidate the process on your own.

Priceless Expertise

Specialists are called specialists for a reason. PCB assembly services are what they live and breathe day in and day out. They know the industry best and are already one step ahead in thinking about potential issues you might not have even thought about, such as:

- Lead times

- Design flaws

- Conflict materials

- Intrinsic safety

Think about all the potential hassles that could be avoided by taking your project to a PCB contractor where they can spot a design problem before it goes to market. That same partner can also help you redesign or refit a board for better manufacturing efficiency. This scenario happens all the time with PCB assembly outsourcing.

Focused Design

A contracted company can lift a giant burden off your hands, allowing you to focus on more important aspects of the PCB design. With your team’s collective hands and minds free, you can focus on engineering or another aspect of building your business. Your resources may be better suited for marketing your product or breaking into a new market.

Shorter Lead Times

Your PCB contractor will likely have long-standing relationships with multiple component makers. The vendor will have an established supply chain with part brokers and other people who may benefit your lead times.

Assembling circuit boards requires a larger team and more space than your facility is prepared to handle. If you don’t have the team and space, it will be difficult to get orders to customers in a timely manner. However, an electronic manufacturer with a sole focus on manufacturing and assembling PCBs can fulfill an order quickly and efficiently.

Higher Capacity

Outsourced PCB assembly benefits include a larger team and more space to work with. In addition, a contractor understands the economy of scale. Once you get into the 10,000s in order volume, you may need to redesign the board to make it more manufacturable on a larger scale. A trusted and experienced assembly service can help with that. If you want to assemble high-volume orders on your own, you’ll need ultra-expensive mounting and inspection equipment to meet capacity needs.

Options for Aftermarket Services and Obsolescence Management

A PCB manufacturer is a business partner with a vested interest in your success. The right vendor is a partner in everything from PCB design layout to the distribution process and beyond. The right vendor will include an on-staff engineering team to help with redesigns. This is a significant benefit if you’re attempting to focus on a new product but also need someone to manufacture a legacy product.

After the product hits the market, the partnership continues as a full-service PCB vendor can perform a failure analysis.

Conclusion

For an all-in-one manufacturing experience, contract PCB fabrication is the best solution. To enjoy additional benefits like obsolescence management and design assistance, and for overall peace of mind, make sure your partner is an all-in-one, domestic contract manufacturer.

Levison Enterprises is the turnkey ECM partner you’ve been looking for. Contact us today to learn more about our capabilities or to get a quote on your next build.