How to Navigate the Chip Shortage in Electronic Manufacturing

With the increased need for computer chips in more and more consumer products, the chip shortage has been felt by nearly every industry. The combination of increased demand, decreased production due to the pandemic, and the lack of authentic data of what is needed are all contributing to the shortage, and electronic manufacturers are learning how to navigate the shortage rather than attempting to wait it out.

Why Is There a Chip Shortage?

Many chip assembly lines are in Southeast Asia. New coronavirus infections have halted these lines yet again, unfortunately before the production deficits had been made up from delays earlier in the pandemic. In addition, the need for chips continues to rise, which is creating an increased margin between supply and demand. Some of this comes from companies who canceled earlier orders due to their own manufacturing shutdowns, and need those supplies now that they are resuming business as usual. Some companies are placing orders larger than what they actually need for production, as they assume suppliers won’t fill the entire order. All of this combined makes it difficult for the chip assembly lines to know what is actually needed, and they are struggling to fill the orders.

How Does the Chip Shortage Affect Manufacturing?

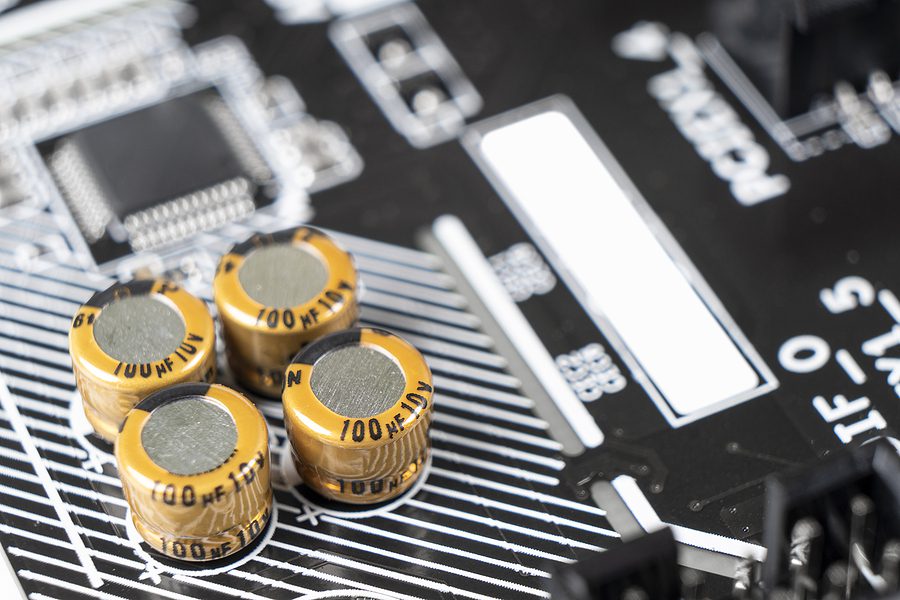

These computer chips are the brains behind all modern electronics and connected devices. Even without a shortage, they are in high demand. As more consumer goods become computerized, the demand continues to rise. Everyone is feeling the pinch from the chip shortage. Nearly every industry has developed a need for these chips, and electronic contract manufacturers cannot move forward with their projects until they have the materials they need. This is increasing lead times across the board, trickling down from the manufacturers to the consumers, as well as driving up prices due to the low supply and continuous demand. Current projections expect this shortage to last into 2023 and possibly beyond.

Options for Electronic Manufacturing During the Chip Shortage

Waiting it out isn’t the only possibility for manufacturers during the chip shortage. When you choose a turnkey ECM like Levison Enterprises to partner with, you will have access to design specialists, engineers, and manufacturing experts who can re-engineer your board to decrease delays due to the chip shortage.

On-site engineers will understand your project from both the design side and the manufacturing side and can incorporate the right set up and materials to get your project through production in the most efficient and cost effective way, without sacrificing any quality or functionality.

Working on optimizing the design is cheaper and quicker than redoing the entire project, and engineers are trained to think through the design and manufacturing process to come up with alternative solutions. Engineers can help choose components with predictable life cycles, which will mitigate the risk of unforeseen delays.

This single-vendor approach will centralize your project management, parts procurement, design reviews, prototyping, and testing. A turnkey manufacturer will fabricate and assemble your PCBs, as well as procure and manage your components. With a vetted supply chain, forecasting capabilities, and supply chain management in place, you will position your project in the best hands to keep it moving forward.

Start Your Quote Now!We can’t do anything about the chip shortage, but with an experienced ECM partnership, you’ll be able to streamline your design, reverse engineer based on component availability, and deliver a high-quality product to your end users. When you are looking for an ECM for your PCB manufacturing needs, a domestic turnkey ECM is well worth the investment, and Levison Enterprises can help give you next build some legs. Contact us for a quote.