How to Decrease Your PCB Spin Time

Turnaround time refers to the time that it takes for your design to go through the manufacturing process and be ready for you, but turnaround time itself is ambiguous in the scope of a design project moving through prototyping, testing, and manufacturing. Spin time, the time it takes for the PCB board to move through the prototyping phase, is one of the most important factors in determining turnaround time. If you are able to optimize your PCB spin time, you will have a more successful project.

Why is PCB Spin Time Important?

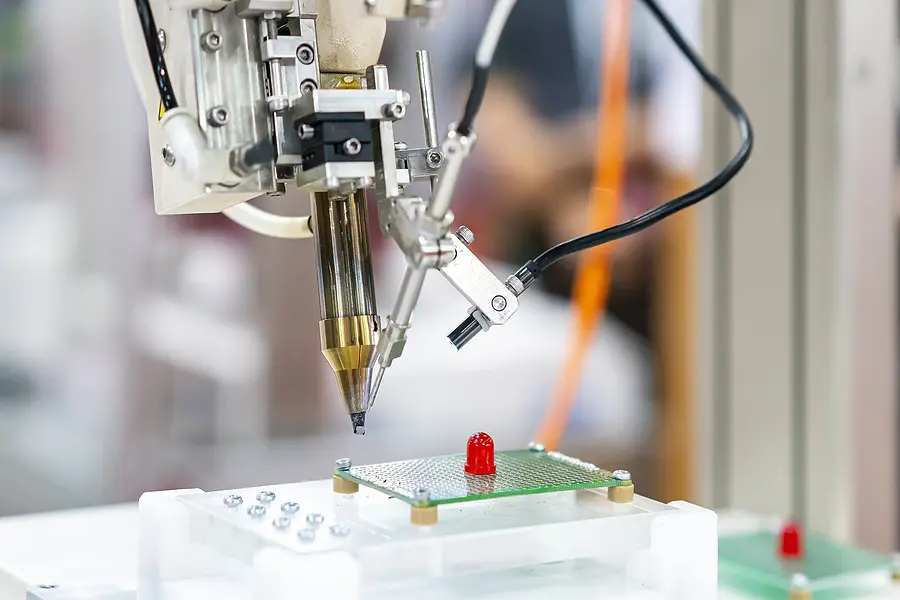

The development of the prototype is the most important stage of a new product. During prototype development, the design will be fine-tuned to ensure the PCB functions as it should. After completion, testing, and validation, your ECM will move the design into the manufacturing stage of development. Prototyping will typically require several board “spins” – which is simply another way of saying board fabrication or construction – before the final design. These spins will help the board reach optimal function and quality. The fewer spins required, the less overall development turnaround time, which will decrease development costs too. A quick spin time will also build client confidence and trust, as a shorter PCB spin time will help you deliver on or ahead of schedule.

How to Optimize Spin Time

There are several ways to optimize PCB spin speed and quality. You can improve the board build process by:

- Optimizing component selection.

- Acquiring and utilizing your ECM’s design for manufacturability (DFM).

- Designing your product for simplicity.

- Avoiding common quote delay issues.

- Ensuring that your ECM has an agile manufacturing process.

When you choose an ECM, look for a partner who focuses on these strategies to optimize spin time and one that can ensure your product will move through the development, prototyping, and manufacturing phases efficiently. You need to know your partner, their processes, and their capabilities before determining whether or not they will be a good fit.

Advantages of a Turnkey ECM

When looking for an ECM partner for your PCB development and manufacturing, focusing on those who can provide a turnkey service. These shops can most effectively optimize your PCB spin time. A turnkey partner will be able to take your project through the entire process from design to delivery, which will streamline the process, leverage on-site engineers throughout the prototyping stage, and allow for fewer errors as your project moves through the process. A qualified turnkey ECM will have:

- Design services available.

- Design for Manufacturing (DFM) strategies.

- Engineering Team On-Site.

- Prototyping Capabilities.

- Reputation of Reduced Development Time.

- Broad Industry Experience.

- Established Counterfeit Parts Mitigation Processes.

- A PFEMA (Process Failure Mode and Effect Analysis) Tool.

Choosing a turnkey ECM can reduce your PCB spin time, as well as ensure your overall product success. Turnkey ECMs have the right professionals in place to collaborate with you throughout the process, taking your design through to a functioning prototype, and finally, a product that brings your solutions to life. Levison Enterprises is a highly certified turnkey ECM with broad industry experience and a talented team of engineers ready to assist wherever needed. Contact us today for a free quote.