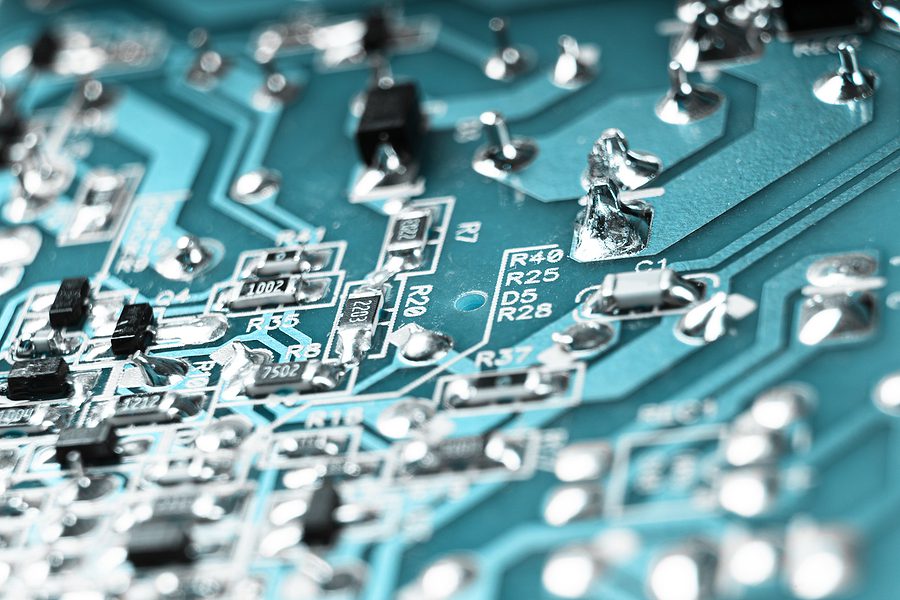

How PCB Design Can Affect the Cost of Your Build With Your Electronic Manufacturer

There can be a big difference between cheap and low-cost. This is especially true when interviewing electronic manufacturers for building printed circuit boards. While you don’t want your PCB fabrication and assembly to break your budget, you don’t want to cut corners so much that you compromise quality just to drive the cost down.

Various factors can influence the price of a circuit board. Keeping these in mind as you develop your PCB can keep costs in check while maintaining the characteristics required of your board.

Size and Shape

The size and shape of your PCBs will vary simply based on how much material is used. It takes more material to fabricate a large circuit board, so obviously it will be more expensive than a small PCB. In addition, the more work required to create the shape of a board will inflate the cost. This includes cutouts, slots, and contours.

Number of Layers

The more layers a circuit board is composed of, the more it will cost. The price will increase with each layer added. You can count on adding 20 to 30 percent to the cost of producing a PCB for stack-ups alone.

Materials Used

The type of materials used to fabricate your PCB will greatly influence the price. Once you vary from common materials, like epoxy resins, the price goes up. However, your PCB performance demands may require higher price materials. Enhanced epoxies are excellent for high-speed designs. Flex circuits may require flexible materials. And durable polyamides are needed for use in harsh environments.

Save Money and Retain Quality

While the operational requirements and performance of your PCB may dictate its shape, size, materials, and layers, there is another big way to reduce fabrication costs. The ECM you partner with may have added benefits built into their manufacturing process that can save you money.

-

DFM

When your ECM completes a Design for Manufacturability (DFM) analysis, time and money can be saved by making sure your design meets the requirements of manufacturing processes to actually produce the PCB. A DFM can uncover design and parts alternatives that can cut down on costs, too. The earlier in the manufacturing process you make any design revisions, the better chance you’ll have of sticking to your timeline.

-

On-site Engineers

Having an ECM with in-house engineers means someone is always there to catch potential problems. If issues are detected, the on-site engineers are there to troubleshoot. Plus, detecting and correcting any potential issues with your PCB early in the fabrication process helps avoid a production slow down meaning your project is completed quicker and at a lower cost.

-

Experienced Turnkey Service

You can also find cost savings when all aspects of your manufacturing – from beginning to end – all are completed under one roof. You will typically be able to negotiate a better price with a single turnkey manufacturer than if you were to hire separate companies for various stages of production. A single provider may also suggest ways to streamline manufacturing to save even more money.

-

Choose a Domestic ECM

Shipping, customs regulations, tariffs, and possible translation issues can send your budget skyrocketing. You can eliminate these line items by working with a domestic ECM.

The right manufacturing partner means you can get the PCBs you need at the price you can afford. Levison Enterprises is an ECM you can trust to help you cut costs on your projects without sacrificing quality. We are confident we can supply trustworthy electronic manufacturing services at an affordable price that works for you. Contact Levison Enterprises today to see how we can put our services to work on your next PCB project.

Start Your Quote Now!