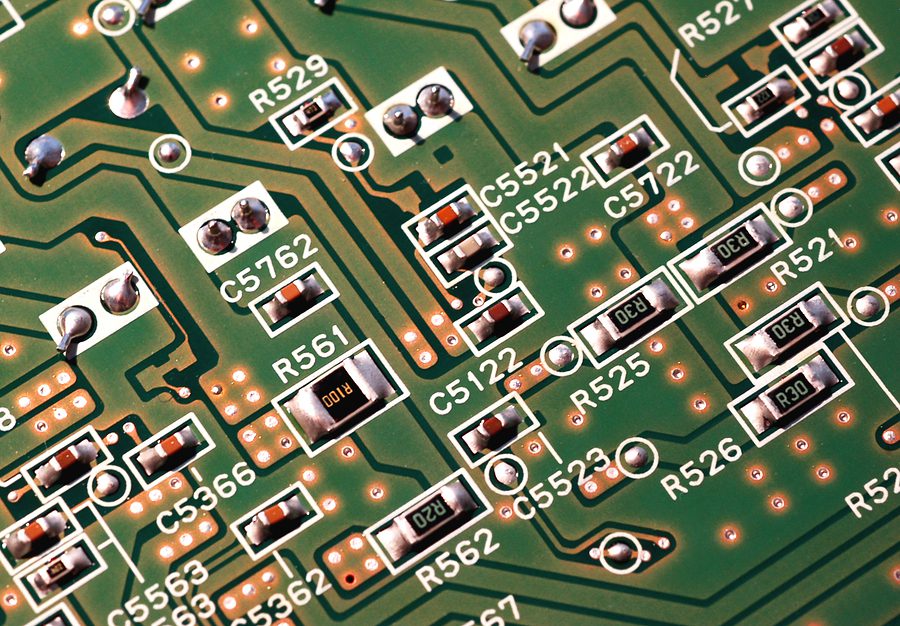

How Counterfeit Parts Affect the Printed Circuit Boards in Your Electronic Manufacturing

In our ever-evolving technological world, we put our lives in the hands of many different electronic components every day. Modes of transportation, our home electronics, and even our office and work spaces are often in the hands of all types of electronic manufacturing. We may never give their performance a second thought, but would you feel different if you knew they contained counterfeit parts?

Counterfeit Parts Can Be Big Business

There’s a lot of money to be made when it comes to all sorts of technology, so counterfeit goods are just as big a business, enticing consumers with a price that sounds almost too good to be true. However, counterfeit parts can turn up in even the most reputable of electronic brands, contributing to poor performance and reduced effective lifespan.

A stereo that has noticeably poor sound quality can be an annoyance, but when counterfeit parts turn up in electronics manufactured for government or military entities, they can be a matter of life and death. That’s why supply chain management is an integral part of ensuring your components are manufactured to the highest standards.

You may think counterfeit parts are only a risk to consumers looking to save a few dollars, but it’s a problem across the whole industry. In a survey of the United States’ defense supply chain conducted in 2010, there were over 1,800 instances of counterfeit parts. Navy helicopters and Air Force aeronautics were two of the more shocking places counterfeit parts were found, and they were in components produced by well-known and reputable contractors.

Supply Chain Integrity

Speak of supply chain management, and you may think only of maintaining inventory and keeping an eye on your bottom line. But when it comes to electronic manufacturing, the supply chain is the lifeblood of your project. One counterfeit part that makes its way into your components can have a disastrous effect on the whole project.

When you go seeking an electronic contract manufacturer, understanding their supply chain logistics is one of the most important factors. Every part that goes into your project needs to meet your exact specifications. At Levison Enterprises, we’re a one-stop-shop for all your ECM needs. That means from the beginning of your project to the end, we handle it all. Design, prototyping, and manufacturing is all done under one roof. To us, knowing exactly where and when your part was manufactured, and how it got to us, is imperative to ensuring the quality of your project.

For us, it all comes down to a fully-vetted network of suppliers from credible parts suppliers. There are no fly-by-night supplier parts entering our manufacturing lines, and for good reason. We stake our reputation on everything we produce. Promising and delivering on the highest-quality components means going the extra mile. We take our manufacturing very seriously, which is why we strive to provide the best customer service to all our partners. For your next project, contact our experienced team of designers, engineers, and manufacturers and experience the Levison Enterprise difference for yourself.

Email Sales