Find the Right Medical Device Manufacturer for Your Project

Medical device companies understand the significance of selecting the right medical device manufacturer for their medical devices, as it helps them convert their ideas into working prototypes and finished products faster, saving both time and money.

Whether you are new to medical device development or a long-standing company with an impressive track record, sometimes you need a little help getting a project off the ground.

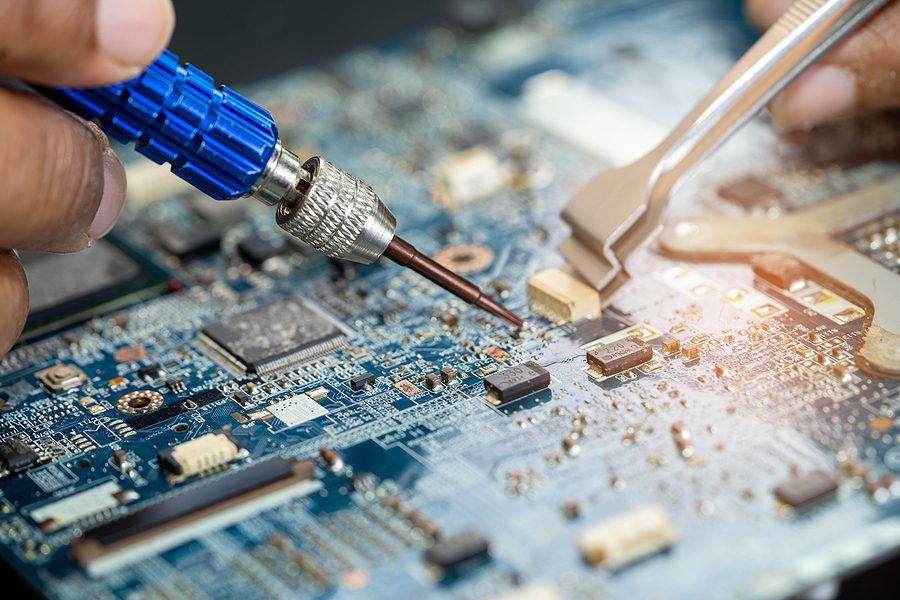

Working with a turnkey ECM is the perfect solution as they can handle the manufacturing in addition to the design, engineering, and fulfillment services for your cutting-edge medical device. A turnkey ECM can step in at any time from initial concept to anywhere in the development process and get it market-ready within compliance standards. The best part is everything is done under one roof.

However, not all ECMs are created equal, so how do you ensure you’re hiring the right ECM for your medical device? Here are some things to keep in mind while searching for a manufacturing partner.

Certifications and FDA Registration-ISO 13485

The ISO 13485 certification is one of the most essential standards for medical device designers and manufacturers. This standard defines a broad range of requirements on quality management systems (QMS) for medical devices and equipment. Since the medical device industry is so highly regulated, OEMs need assurance that their new products will be in full regulatory compliance once their product hits the market. Therefore, it’s imperative to find an ECM partner that is ISO 13485 certified and FDA Registered.

Industry Knowledge and Compliance

It’s important that your ECM is well-versed in the medical device industry. Not all ECMs have experience in all areas. Compliance with industry laws, regulations, guidelines, and specifications can affect every phase of the manufacturing process. You want to ensure your ECM can handle the project and meet the stringent industry regulations you are under.

Engineers On-Site

Outsourcing your medical device to an ECM with in-house engineers ensures your product will be overseen by experts looking for any issues that may arise. If a problem is detected, they are ready and available to troubleshoot on the fly.

Reverse Engineering Capabilities

Component obsolescence is one of the main challenges for electronic device manufacturers. Widely used parts can’t be manufactured fast enough or may be unavailable. Designers and manufacturers must find a way around component obsolescence and seeking alternative parts is usually the answer. However, replacing a component is not always cost-effective. The solution can be retrofitting or reverse engineering, allowing older technology to adapt to newer specifications with widely available parts. Retrofitting and reverse engineering can help bring older technology up to date, meet new performance standards, and streamline older product designs to contemporary configurations.

Testing and DFM Analysis

There are several benefits to incorporating a DFM analysis into your process. The DFM approach allows you to catch any early mistakes in the design. Finding errors when the product is in the later stages of fabrication and assembly can result in low quality or a failed product. The closer the fabrication is to the end, the more expensive and difficult it will be to diagnose what went wrong. Plus, you will attain more consistent quality control and higher performance with a DFM analysis.

Turnkey Domestic

The medical device market is growing rapidly, and the industry is becoming more competitive as innovation continues to meet the need of medical devices for consumers and the healthcare industry. As the demand rises, medical device manufacturers stay competitive by keeping their costs down and their time to market short.

Partnering with a domestic, turnkey ECM is one of the best ways to remain competitive. A turnkey ECM is set up to meet every potential need of your project. When utilizing a medical device manufacturing partner with the ability to take on multiple aspects of your build, your project will never lose a day during the transition between subcontractors, resulting in faster timelines.

Prototyping Capabilities

The right company to partner with is one who uses prototyping. A design on paper isn’t worth much if you don’t know it works. Prototyping is the only way to know how your design will function. Partnering with an ECM who has prototyping capabilities will do just that. Prototyping lets you do small runs with your product to test the functionality.

Packaging and Shipping Services

Packaging and shipping services should never be overlooked when choosing an ECM partner. A manufacturer can help free up your time by handling the packing and shipping of your product directly to your customers. Working with a company that can get your devices where they need to be, when they need to be there, gives you peace of mind.

Why Partner with Levison Enterprises?

Launching a new medical device requires many resources. When you outsource your medical device manufacturing to a turnkey partner like Levison Enterprises, you get the complete package including designers, engineers, researchers, equipment, and tools on-site with regulated and optimized processes already in place. From design assistance, prototyping, troubleshooting, testing, and manufacturing, the necessary experts and manufacturing equipment are available in a single facility, saving you time and money.

As a registered FDA manufacturer with ISO 13485 certification by NSF-ISR, Levison Enterprises has the experience and capabilities to take your concept or device to market. From the prototype, we can evaluate your device in the field, making tweaks and adjustments as needed, before mass production.

Levison Enterprises is the medical device partner you can trust and count on to manufacture your next great idea. Contact us today to learn more.

Start Your Quote Now!