Exploring the Difference Between Cable Assemblies and Wire Harnesses

To the layperson, cable assemblies and wire harnesses sound like the same thing. The fact that the terms get thrown around interchangeably by those in the know contribute to the confusion. But while the two share many similarities, there is a difference.

The basic differences between the two come down to what they are built for. One exists for purely organizational simplicity, while the other is designed to offer more protection from the environment. There are other more technical differences as well.

Wire vs. Cable

The first difference has to do with what each word specifically describes. Again, the words “wire” and “cable” get used for each other, even by those who know the difference. The word cable, however, refers to two or more wires that have been run together, while wire refers only to a single strand, with or without a sheath.

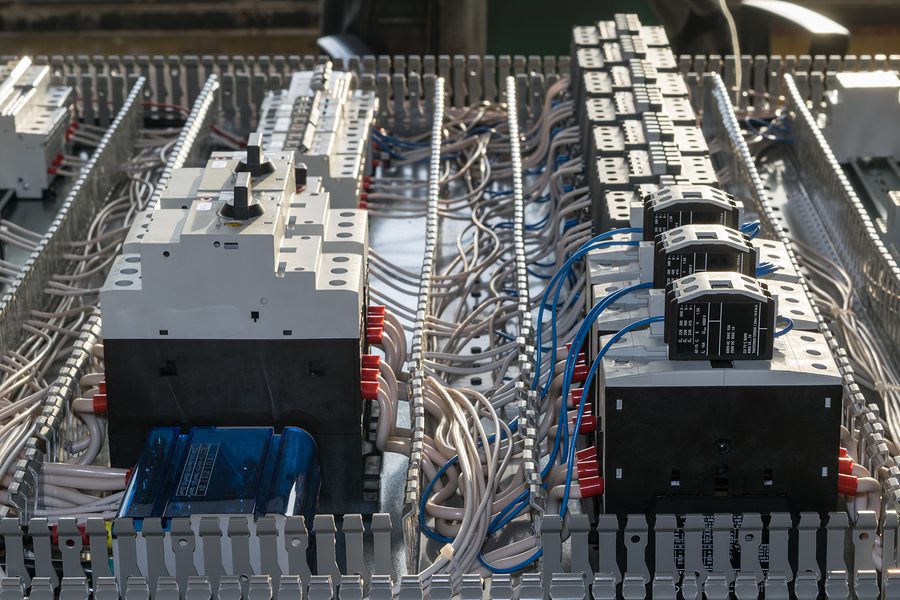

Wire Harnesses

A wire harness, then, only refers to a group of wires that have been grouped together for the purposes of keeping them better organized. The wires can be bound together as simply as with a wire tie, or they may also be bound by a thermoplastic sheath. No matter how they are grouped, it is done simply to make sure the wires stay organized and for easier connectivity. Typically whatever groups the wires together does not offer any environmental protection for the wires.

Why do companies opt for wiring harnesses? They are a low-cost solution, and they are easy to modify if need be. For instance, if another wire needed to be added to the grouping, it would be easy enough to add it by either removing the wire ties, regrouping wires, and applying a new tie. Or, if the harness is bound by thermoplastic sheathing, removing it by cutting it and applying a new sheathing.

Either way, wire harnesses are going to be found only in indoor applications, where the operating environment involves little to no stressors.

Cable Assembly

When two or more wires are bound together by a protective jacket into a single strand, it is referred to as a cable assembly. That jacket may be thermoplastic, vinyl, or rubber, depending on the environment it will be operating in, as well as other specific needs. Different jacket materials may give the assembly different desired properties. Some applications may call for size constraints, while others may be looking for flexibility or routing advantages. Due to how they are manufactured, cable assemblies are also designed to function like one individual wire.

Cable assemblies are designed to withstand certain heat, friction, moisture, and other environmental challenges. For this reason, cable assemblies are best for outdoor applications, or operating environments that are less than ideal. A cable assembly can also be designed to handle larger electrical loads than a wire harness.

Regardless of whether you need a simple wire harness, or something more involved like a cable assembly, Levison Enterprises has you covered. While off-the-rack solutions may seem to be a more cost-effective or time-sensitive solution, custom solutions are more attainable than you may realize. Contact Levison Enterprises today to learn more about our turnkey solutions for your next ECM project.

Start Your Quote Now!