Expectations of a Robust Electronic Manufacturing Supply Chain Management Process

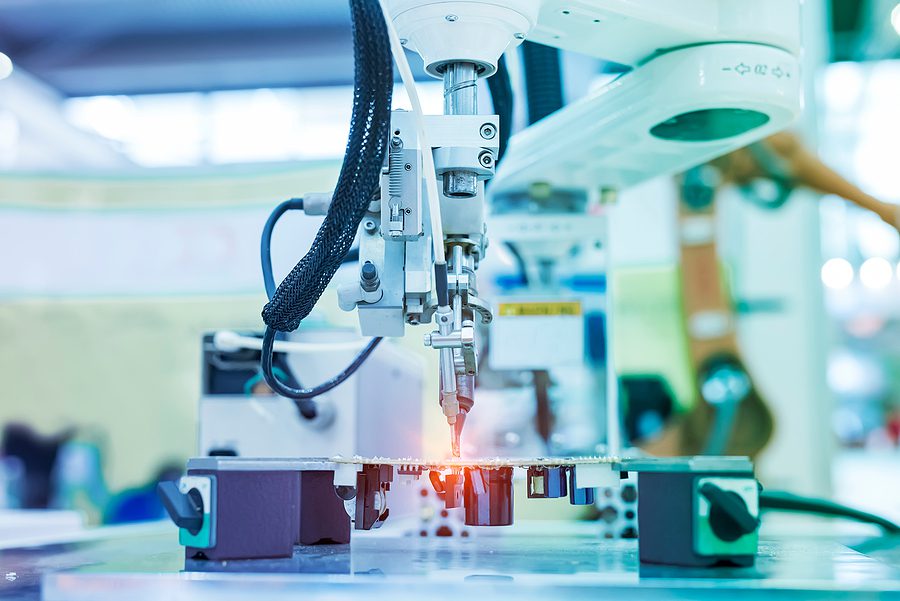

A solid electronic manufacturer will already have a counterfeit electronic component detection and avoidance plan in place. After all, a healthy supply chain is vital to your company’s success, and your ECM knows that. You can’t run the risk of any issues falling between the cracks. Meanwhile, counterfeit electronic components continue to be a big problem. This is why many are turning to electronic manufacturing partners for their expertise in supply chain management.

The Problem with Counterfeit Parts

Counterfeit components can bring a myriad of problems to your project. When fake or poor-quality parts are used in your project, you run the risk of product failure, personal injuries, reduced reliability and product recalls, potential loss of contracts, and shutdown of manufacturing lines.

However, it is often extremely difficult to determine if parts are counterfeit. They will appear to be genuine. They simply are not manufactured to the same quality standards, though. This can include:

- Untested parts.

- Parts that do not have the proper internal structure.

- Refurbished parts sold as new.

- Parts with a different surface plating or finish than were ordered.

- Parts sold with labeling that misrepresents form, function and/or grade.

Counterfeit components can be convincing. Most will look authentic, be functional, and even pass some levels of testing. The fact that they are fake is usually not discovered until it is too late. This is why robust supply chain management, along with counterfeit electronic component detection and avoidance, is key.

Supply Chain Best Practices

Outsourcing your project is a big deal. How do you know the parts being put into your project meet the high standards you are expecting? A successful counterfeit electronic component detection and avoidance plan will include a multi-prong approach. An ECM with good supply chain management will follow these common processes:

- Practice Parts Inspections and Counterfeit Avoidance

Independent testing of parts coming from suppliers does a lot to reduce the risk of counterfeit components entering your supply chain. A visual inspection should include an examination of material type, surface finish, dimensions, and tolerances. Further inspection may include x-ray, electrical tests, scanning acoustic microscopy, and decapsulation.

- Trusted, vetted supplier network

Securing your supply chain relies on a trusted network of thoroughly vetted suppliers. Using authorized suppliers and/or original components manufacturers will greatly mitigate any counterfeit threat.

- Routine Checks of Supplier Stability

Top ECMs will regularly check the stability of their suppliers. This should include looking for any changes in ownership of a component company, by looking for ownership changes and any shifts in the supplier’s business circumstances. Regular performance reviews should also be verified. In addition, it is also a good idea to routinely check the validity of your suppliers’ environmental and regulatory compliance certifications.

- Continuous Monitoring

The process of counterfeit electronic component detection and avoidance should never be a one and done. Consistent monitoring is required for successful counterfeit risk mitigation. Your ECM should regularly monitor supply chains for:

- Violations with EPA, OFAC, or OSHA.

- Quality assurance.

- Sudden increase in lag times.

- Communication breakdowns.

Zero Counterfeit Objective

Levison Enterprises knows counterfeit electronic component detection and avoidance must be taken seriously. That is why we have a Zero Counterfeit Objective In place.

It is Levison Enterprises’ policy to prevent the procurement, acceptance, and shipment of counterfeit or suspect products. We stand by our commitment to continuous improvements and customer satisfaction through precise inspections that carefully screen for the threats of counterfeiting and ensure delivery of a quality product to you.

Start Your Quote Now!You need an ECM you can trust. Let Levison put our Zero Counterfeit Objective, proven network of suppliers, and outstanding supply chain management skills to work for you. Contact us today for a free quote and to guarantee the integrity of your next project.