Does Your Project Require a Multilayer Printed Circuit Board?

Printed circuit boards are the core of today’s electronic devices. Simple electronics with limited functions may only require a one layer board, while more complex electronic devices use a double-layer printed circuit board. As the complexity of electronic devices increases, double-layer boards may no longer be enough. Multilayer printed circuit boards (PCBs) are gaining popularity throughout many industries. Demand for small, yet highly functional designs benefit greatly from using multilayer printed circuit boards.

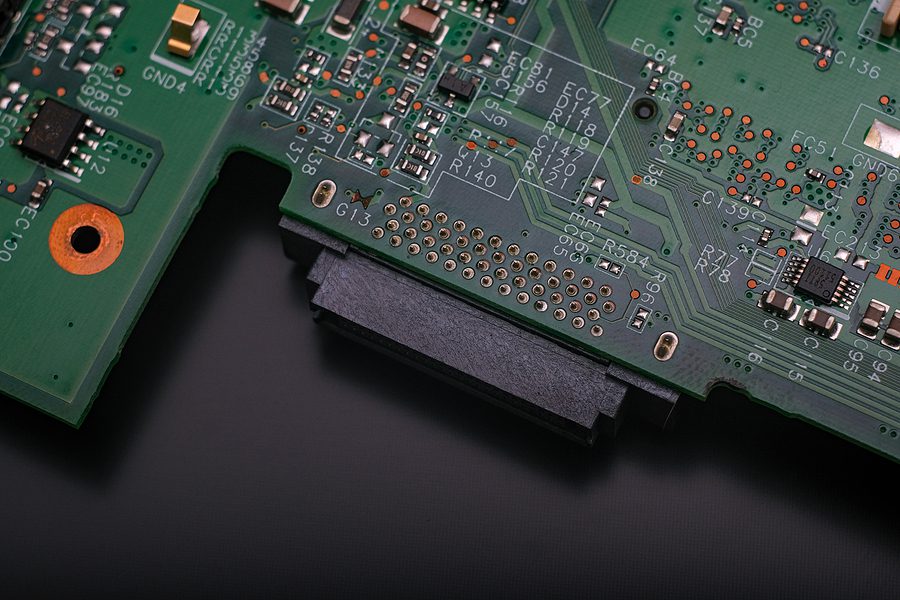

What is a Multilayer Printed Circuit Board?

A multilayer PCB is one that is made with three or more conductive layers. They are typically several layers of double-sided boards, which are then laminated or glued together with layers of heat-protective insulation in between the boards. The construction is arranged so the layers on the surface sides are available to connect to the environment. The electrical connections between the layers are done through holes. These methods allow you to create highly complex PCBs in a much smaller footprint. They are available in a variety of sizes from four to twelve layers, most often with an even number of layers, although more layers are possible.

Benefits of a Multilayer PCB

Why would you need a multi-layer printed circuit board? As electronics become more sophisticated, more complex PCBs are required. Because PCBs were limited by surface space, design became more difficult. Single- or double-sided PCBs were no longer enough to meet both the size constraints and necessary performance we’re looking for. A multilayer PCB can pack a lot of power into a format that is a fraction of the size of a double-layer PCB. The major benefits of a multilayer PCB are:

- Small Size

- Lightweight Construction

- High-Quality

- Increased Durability

- More Powerful

- Enhanced Flexibility

- Single Connection Point

Although the benefits are great, it is important to note that multilayer PCBs do come at a higher cost and will require a greater level of expert manufacturing. Skilled designers, engineers, and manufacturers are needed to produce these boards, and finding an electronic contract manufacturer who can handle the complexity of the board becomes even more important.

What Applications Usually Require a Multilayer PCB?

There are several industries that often require a multilayer PCB.

-

Medical Devices

The medical device industry is focusing on making devices smaller, and multilayer PCBs can meet this demand. Small, lightweight, and powerful PCBs can provide less-invasive devices with high accuracy and functionality.

-

Industrial Electronics

Industrial electronics have different needs than consumer electronics. Harsh environments, such as extreme temperatures, vibrations, pressure, and shock are all potentially faced with this type of PCB. Durability becomes extremely important and multi-layer PCBs meet this requirement with ease.

-

Military

Military components need to be able to withstand harsh environments, such as extreme temperatures, and multilayered PCBs can be assembled with military grade components to withstand these conditions while still meeting the small size and high functionality necessary.

-

Aerospace

The aerospace industry has a great need for high-performing, sophisticated, small devices that are made possible by assembling multi-layer PCBs.

-

Defense

Multilayer PCBs are favored by the defense industry due to their compact design, low weight, high speed, and reliability.

Start Your Quote Now!The demand for multilayer PCBs will continue to increase as technology continues to evolve and the need for high-speed and high-performance products continue to rise. Finding an ECM partner with the experience and capabilities for multilayer PCB solutions will ensure that you will remain on the cutting edge of electronic production. For a quote, please contact Levison Enterprises today!