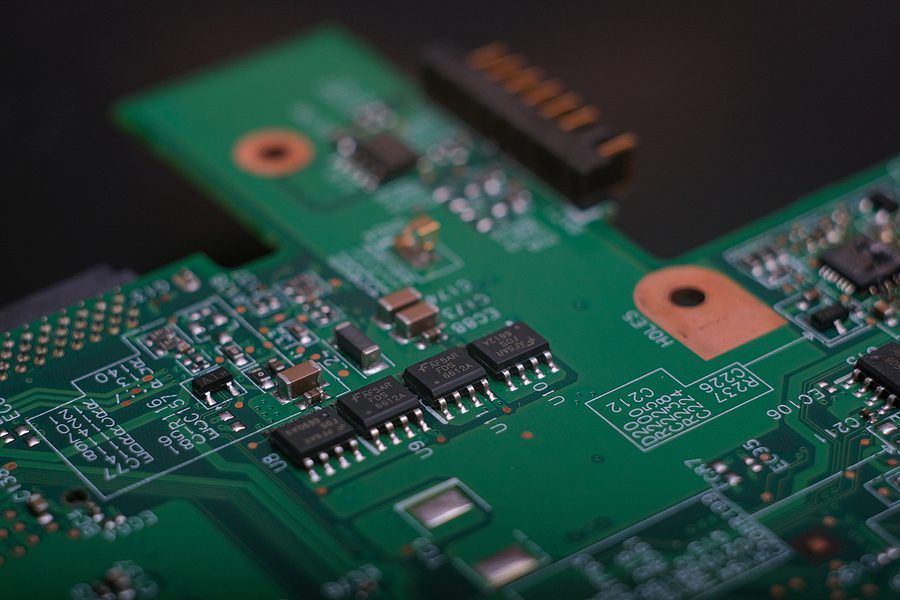

Cutting Corners in PCB Manufacturing is Expensive

Cutting corners may mean cutting initial costs and making a project seem like a low investment for a high return, but trying to decrease your bottom line this way is almost never the most cost-effective choice and will likely hurt your product and reputation in the end. While that may seem impossible, it is very common in PCB manufacturing. The lure of a low price can be difficult to pass up, but it’s important to know what that low initial cost will cost you in the end.

A Domestic Partner Can Benefit Your Company

Overseas facilities will often try to woo you with a low-cost PCB manufacturing process, but it is important for companies to really look into that cost and determine what they are really saving. Overseas PCB manufacturing can extend your timeline significantly and will often come with other risks, such as inauthentic parts, errors due to communication issues, or a breach in confidentiality. A domestic partner will circumvent many of these issues. Time difference and language barriers won’t impact communication, shipping of completed components can be handled efficiently, and all troubleshooting can be dealt with during manufacturing, rather than after an expensive product run.

If there’s an issue with your product built by an overseas partner, the time spent rectifying the mistake will cost plenty, but you’ll also be dealing with a product run of defective devices and potentially missed deadlines by having to start over. With a domestic turnkey partner, problems like this will be caught early, and because you aren’t waiting for a shipment from overseas, a slight delay may not throw your timelines completely off the mark.

A Turnkey Facility Saves you Time and Money

All PCB manufacturing facilities are not created equal. Bargain PCB manufacturers may not be able to offer the same level of services, and they may need to send parts of your build to a third party manufacturer. The more hands in the project, the more potential you have for things to go a little off track. When building a budget for your product, you may be tempted to go with the most inexpensive facility, counting on the project going smoothly. However, a turnkey facility will often save you time and money. When the entire process can be handled in one facility you will not lose time in manufacturing to a third party shop, errors can be found early and quickly addressed, and the chances of the project ending on time is much greater. We all know time is money, and ultimately a reliable product is the result of a well-executed manufacturing plan.

The Right ECM Will Save You Time and Money

When you find the right ECM, you will save both time and money in the long run. You will have a product that is manufactured correctly, efficiently, and reliably. A turnkey, domestic ECM is the right choice to get your product to market in the most efficient and cost-effective way. A quality ECM will include services such as design support, prototyping, in-house engineering services, industry knowledge, testing, manufacturing, packing, and shipping. In addition, choosing the best ECM means that your product will be manufactured by professionals with a vetted supply chain, the right certifications, and a commitment to continuous improvement. Cutting corners on any one of these services can cost you dearly in the long run, but using a partner with everything you need in one place ensures a successful project from design through to delivery.

When you invest in quality, you avoid manufacturing errors, delays, and unexpected expenses. Any PCB manufacturer can handle assembling a circuit board, but there are distinct differences in the quality of the technology you will receive from these facilities. You want an ECM partner with a reputation for consistent quality and success in every product they handle. Levison Enterprises can help. If you’re looking for a reliable, turnkey ECM for your next project, contact us today.