Current Challenges in Supplying Electronic Manufacturing

The electronic manufacturing industry is a big business that keeps on growing. The competition is fierce, so survival requires flexibility. For an electronic device company to thrive, it must adapt to evolving technology and overcome current and emerging challenges.

While the electronic manufacturing industry faces new challenges, there is also opportunity. To catch up with the competition, it’s imperative to remain relevant and current about designing trends in the industry. Therefore, an ECM company needs to be flexible and quick. To emerge as a successful company, one must be able to overcome existing and future market challenges. Here are some of the current difficulties in supplying electronic manufacturing today:

Ongoing Supply Chain Concerns

As a result of the recent pandemic, manufacturers experienced a significant delay from their suppliers. Businesses are now trying to adjust to new ways of living and working in the post-pandemic environment, including

- Labor shortages

- Component shortages

- Shipping delays

Therefore, the electronic manufacturing sector must assess what has changed and how it might become more resilient to future challenges.

Coupled with an Increase in Global Demand

Even before the pandemic changed people’s shopping habits, the electronic industry experienced increased online sales and acceleration of eCommerce globally. As consumers continue to shop online more often, brands have rapidly changed their strategies.

While the online marketplace is being pushed to evolve to accommodate the growing demand in existing sectors, it’s also dealing with the increased global demand for:

- Electric cars

- Smart devices

- Home office needs

Partner with an Experienced ECM

The process of hiring a new ECM partner is never an easy task. Here are some key areas you should know when vetting a potential electronic assembly partner to ensure you’re making the right choice:

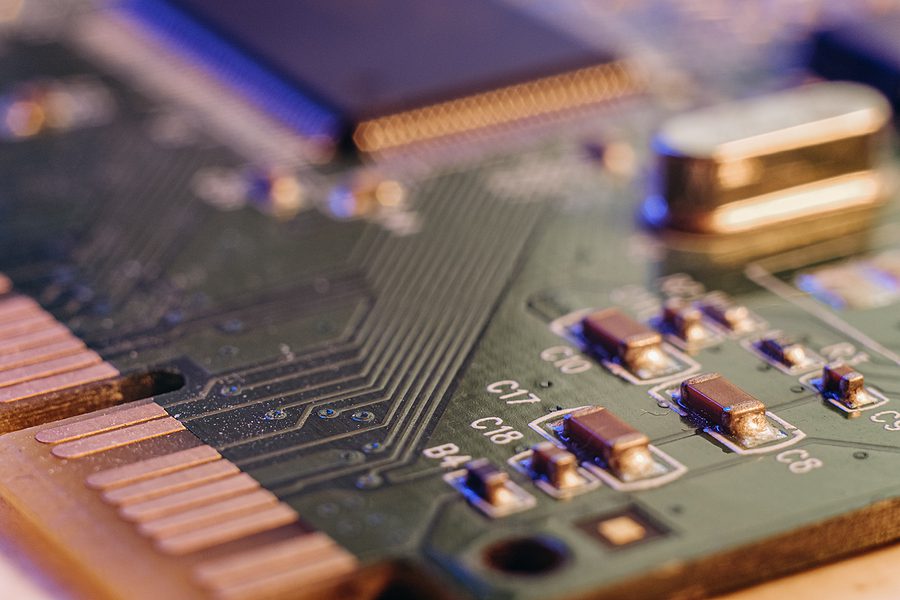

Vetted Supply Chain

An experienced, domestic ECM comes with a vetted supply chain. They will always know the availability of components and be able to accurately forecast the risk of parts becoming obsolete. This allows you to stock up as soon as they determine a part may soon become hard to find. A contract manufacturer proactive in parts obsolescence will have an existing trusted network of vetted suppliers to turn to when a part is in danger of becoming hard to find. This will also enable the assembler to determine if an adequate substitute for the part or an appropriate aftermarket source exists.

Domestic Partner=No Overseas Shipping Concerns

A domestic ECM partner means fewer shipping headaches. Shipping can inflate your costs significantly, and overseas shipping is an expense. In addition, you may be looking at a long shipping timeline. A domestic ECM may be within driving distance, meaning the shipping or delivery will be quicker and cheaper. You’ll have more options available with a domestic ECM, and you’ll avoid customs and tariffs.

In-House Engineers

In-house engineers are critical to the success of your project. The ECM partner you choose should have all the experts required for every project stage, from design through delivery, in-house, and ready for anything that may come up during the design, prototyping, and testing phases.

Parts obsolescence is a big problem in the electronic industry, so finding the right manufacturing partner can significantly mitigate the issue of parts obsolescence. In-house engineers can also offer design modifications to help you avoid a complete redesign for parts availability.

The Levison Difference

Levison Enterprises brings a lot to the table. With them as your trusted electronic contract manufacturing partner, you can rest easily knowing your device will be manufactured by one of the leaders in domestic printed circuit board (PCB) production. From prototyping through final packaging and shipping, Levison Enterprises is with you every step of the way. Contact us today to learn more about our capabilities, or to get a quote on your next electronic build.

Start Your Quote Now!