Considerations for Electronic Enclosure Design

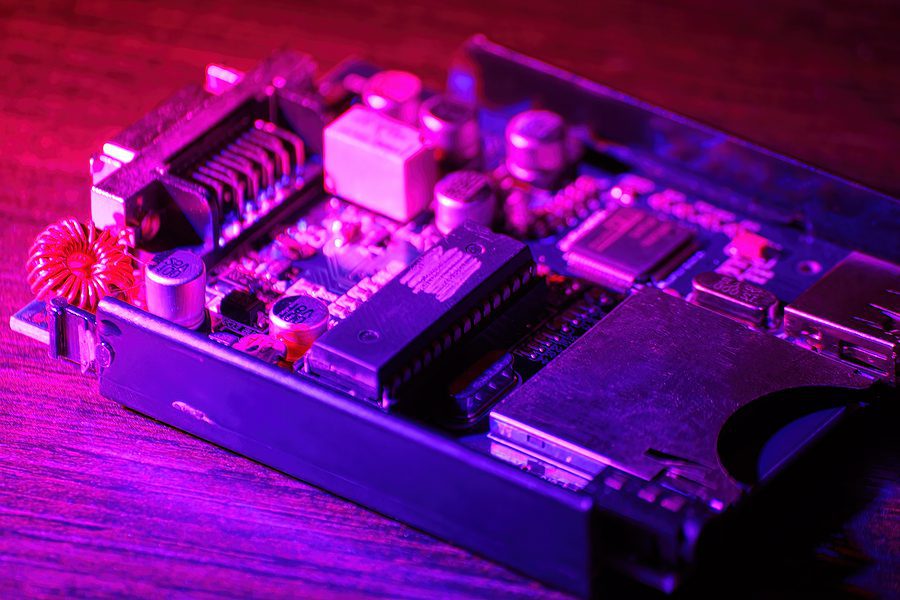

After you have an assembled PCB, you will need to finish the device with a box build, sometimes referred to as a systems integration. This combines the PCB, cables and wires, subassemblies, and the electronic enclosure. When the full box build is complete, your electronic assembly will be carefully protected and ready to function in your final product. Choosing the right electronic enclosure is just as important as the PCB itself, as it will need to withstand the conditions of your end product. When you are looking at electronic enclosure designs, there are several things to consider.

Fit

The right fit is important. To find the perfect fit that will be cost-effective, functional, and safe, use 3D modeling to create an enclosure. The larger the device, the more difficult it may be to create the perfect enclosure. Design-for-manufacturability (DFM) can help you here. When your design team incorporates DFM recommendations, the size and dimensions of your final product can be adjusted to allow optimal space considerations and the right enclosure.

Materials

Different materials have different durability, malleability, availability, and price points. Metal is the standard material for enclosures that need to be durable and cost-effective, but plastic is easier to shape and can easily be customized. When you are considering materials, work with your Electronic Contract Manufacturer to ensure that you are choosing the right material for the needs of your project. If the end product will be used outdoors, underwater, underground, in extreme temperatures, or in a moist environment, the materials you chose for your enclosure will make a big impact. Your ECM should discuss all the possible materials, along with their benefits, drawbacks, and costs, while you are still working on your design. DFM analysis can help you determine the right material from the start.

Transmission

Some enclosures hinder transmission of wireless signals, which is obviously detrimental to many products. Metallic enclosures may be needed for corrosion resistance, but can impact wireless signals. Plastic enclosures work well for transmission of signals, but may not have the durability your end product requires. Work with your ECM to create an enclosure that will not only protect your PCBA, but will allow it to function as designed.

Layout

Think about your end product when considering your enclosure. Although functionality is more important than appearance, the way your product looks will matter to your customers. Look at similar products on the market to get an idea of the appearance and usability of the product, and then work with your ECM to select a thoughtful layout and design that will appeal to your customers and work well with your product.

Compatibility

The final step before production of your electronic enclosure is to compare your CAD to the BOM to ensure package compatibility. Before finalizing, check the entire BOM to make sure there were no errors in communication. You and your ECM can work together to verify that your design and BOM are compatible.

When you are looking for a turnkey, full-service electronic contract manufacturer for your next electronic enclosure, find an ECM who has the right experience, capabilities, and expertise to guide you through the full process and help you choose the right design for a successful end product.

When you partner with Levison Enterprises, we become an extension of your team. From design to production, fulfillment services, and beyond, we are a trusted industry leader. If you’re considering your options for an electronic enclosure for your next electronic device, contact us for a quote.

Start Your Quote Now!