Comparing Domestic vs. Overseas Electronic Manufacturing

Warning: Attempt to read property "ID" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 15

Warning: Attempt to read property "post_content" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 16

Warning: Attempt to read property "ID" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 15

Warning: Attempt to read property "post_content" on null in /srv/users/serverpilot/apps/lev-2023-wp/public/wp-content/themes/lev-2025/inc/cta_shortcode.php on line 16

When looking for an electronic contract manufacturer to partner with for PCB assembly, cost will always be a consideration. Many overseas electronic contract manufacturers will attempt to highlight their lower costs as a primary advantage. In reality, while the initial quote may come in under domestic options, partnering with a domestic ECM will always save money in the long run, as well as provide many other advantages that overseas electronic manufacturing simply can’t. When comparing domestic and overseas electronic manufacturing, it is important to look at the full scope, not simply the initial quote. Quality, IP security, global issues, timeline, and compliance with industry regulations should always be factored into this decision-making process.

Domestic Electronic Manufacturing Produces Higher Quality Products

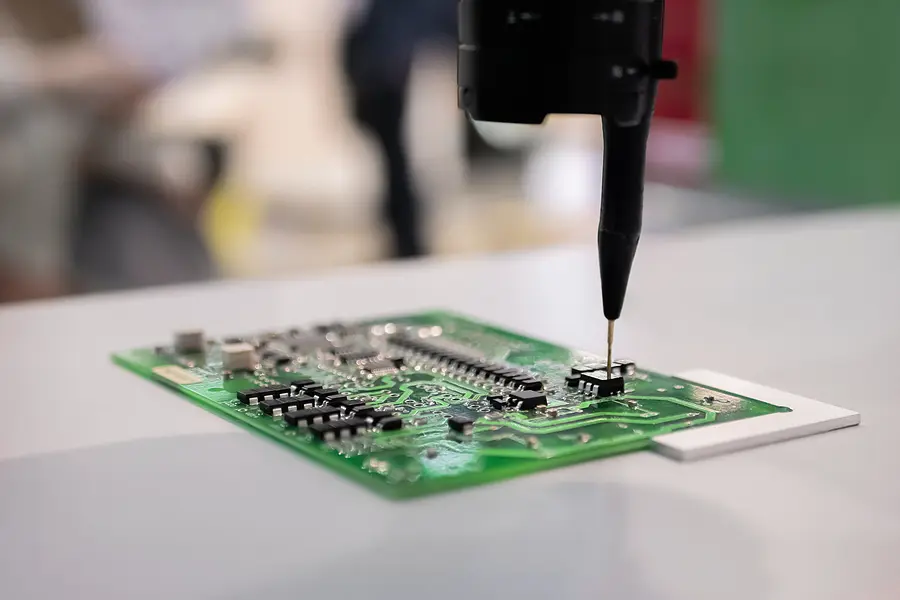

The ultimate goal that will define product success is customer satisfaction, reliability, and durability. High quality products should always be the primary factor when choosing an electronic contract manufacturer. When comparing domestic and overseas electronic manufacturers, evaluating the quality control metrics should factor strongly into the ultimate decision. In overseas facilities, quality control measures are more difficult to track, and the lower cost of labor may indicate a poorly trained workforce. Domestic ECMs are increasing workforce training, focusing on quality control measures, and are investing in their manufacturing capabilities, making the quality of the products superior to those manufactured overseas.

Risk of Intellectual Property Theft is Lowered when Choosing a Domestic ECM

When outsourcing PCB manufacturing overseas, the risk of intellectual property theft is greatly increased. Overseas manufacturing can inspire inferior copies of devices as a product of this IP theft. In electronic manufacturing, IP theft has always been a concern, but domestic electronic manufacturing facilities have far more processes and standards in place to protect all intellectual property during the manufacturing process. There is no need to put your IP at risk for overseas manufacturing, which can cost you greatly in the long run.

Keeping Electronic Manufacturing Domestic

Many overseas manufacturing facilities, particularly in certain countries, have serious pollution issues. As consumers are becoming more environmentally conscious, they are looking into the environmental impact of their devices, including where and how the product was manufactured. Many product developers are taking this into account as they choose their manufacturing partners to maintain their position as environmentally friendly.

Working With Domestic Standards Can Keep You Compliant

Supply chain management is always a concern, and something that you should factor into your decision. With many highly regulated industries, compliance is dependent on very specific methods and avoidance of any risk of counterfeit components. As many industry regulations are country specific, staying domestic for all electronic manufacturing ensures that your ECM will have a strong knowledge of these regulations and will always keep your device compliant. Using vetted suppliers and having a transparent chain of custody will cut down on the risk of counterfeit components that can put your device in jeopardy.

Domestic Partners Help Streamline Communication

Communication with your electronic contract manufacturing facility is crucial during the manufacturing process. When communication is a struggle, the risk of misunderstandings will increase. Even if the overseas facility you are considering communicates in English, language barriers and cultural differences can still result in misunderstandings. While some misunderstandings are minor and easy to remedy, others can result in significant issues. In addition to the language and cultural barrier, the simple concern of time differences can also create issues. The delay in response time due to different working hours will impact efficiency and can ultimately delay the project timeline. When working with a domestic electronic contract manufacturer, time differences are a far lower concern and misunderstandings caused by language and cultural issues will be at a minimum. Your project manager at a domestic ECM will always make sure that communication channels are kept open.

Shipping and Meeting Deadlines is Not a Concern with a Domestic ECM

Partnering with a domestic ECM will save you significant time when compared with overseas electronic manufacturing. Shipping costs from overseas facilities can increase your bottom line significantly, and overseas shipping comes with a long timeline. Domestic manufacturing facilities can offer substantially more efficient and cost-effective shipping options, as many are within driving distance. With a domestic ECM, you can avoid the added costs of customs and tariffs, which will result in shorter lead times. Shorter lead times save money, and will also allow you to meet your projected deadlines.

Comparing Cost v. Value

When comparing domestic and overseas electronic contract manufacturing, it’s important to compare cost with value. While the quote you receive from an overseas manufacturer may come in as a lower number, even when considering shipping and customs fees, the ultimate value of outsourcing to an overseas facility is typically lower than choosing a domestic facility. The shipping lag, delayed timeline, potential for quality issues, and risk of compliance issues should all be factored into the ultimate value of your investment in manufacturing.

When considering your options for outsourcing electronic contract manufacturing, you will have many choices, both overseas and domestic. Overseas manufacturing may offer an initial lower cost than domestic facilities, but all factors should be considered. When considering the increase in quality, safeguards to ensure compliance and IP protection, fewer shipping headaches and reduced timelines, and more effective communication, a domestic ECM makes the most sense. The overall value of your manufacturing investment will be greatly increased. To learn more about our capabilities, standards for excellence, or to get a quote on your next device, contact Levison Enterprises.