Blog

Ensuring Accountability Through Traceability in Medical Device Manufacturing

September 23, 2024

Some industries are more highly regulated than others. The medical and healthcare device industry is one of the most highly regulated, as medical devices, particularly those implanted in patients or worn to monitor and treat serious health conditions, must be safe and effective and cause health improvements rather than putting them at additional risk. To […]

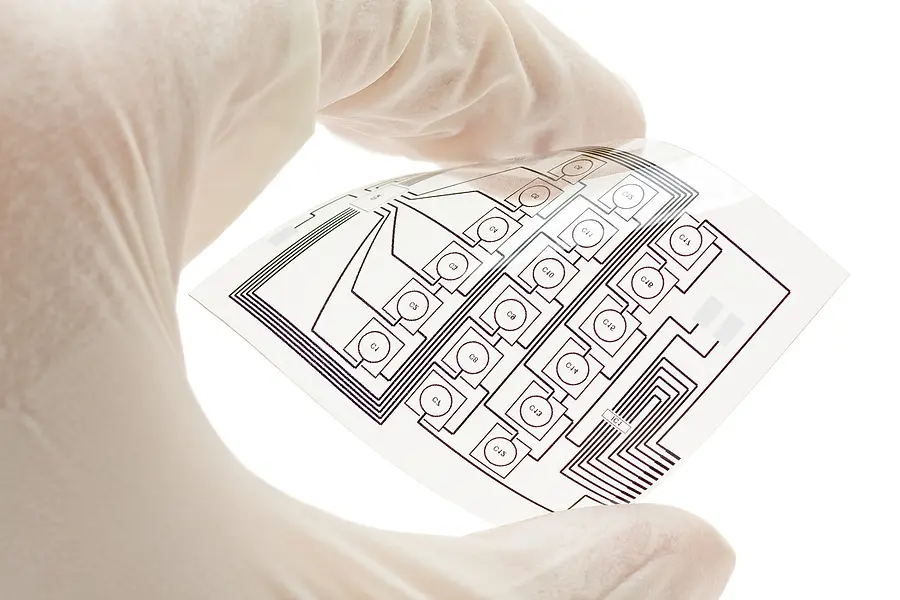

Applications and Advantages of Flexible PCBs in Medical Devices

September 16, 2024

Flexible PCBs are seeing increased use in electronic medical device manufacturing. Many medical devices now include printed circuit boards, and technological advancements have made these devices even more desirable among patients and the healthcare industry. Electronic contract manufacturers skilled in medical device manufacturing have been using flexible PCBs to streamline design, reduce weight, and increase […]

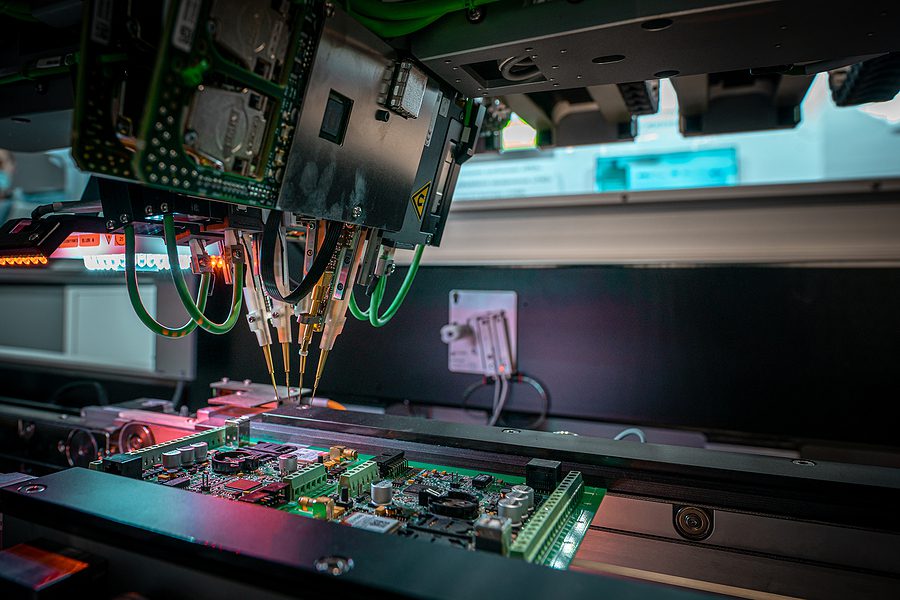

Skilled Engineering in Aerospace Electronic Contract Manufacturing

September 2, 2024

In aerospace electronic contract manufacturing (ECM), skilled engineering ensures the success and reliability of electronic components and systems destined for aerospace applications. From printed circuit board (PCB) design to system integration, engineering expertise is instrumental in meeting the strict requirements of the aerospace industry. In this article, we delve into the importance of skilled engineering […]

Unmanned Systems: Electronic Contract Manufacturing for UAVs and Drones

August 30, 2024

The evolution of unmanned aerial vehicles (UAVs) and drones has revolutionized defense, surveillance, and commercial industries through innovation. These sophisticated flying machines rely heavily on advanced electronics to navigate, communicate, and execute their missions effectively. Behind the scenes of this technological wonder lies the crucial role of electronic contract manufacturing companies (ECMs). These ECMs are […]

Advancing Defense Technologies With ECM Innovation

August 26, 2024

In today’s rapidly evolving global security threats, developing and deploying cutting-edge defense technologies have become essential for safeguarding nations and ensuring military superiority. Among the key players in this technological arms race are Electronic Contract Manufacturers (ECMs), who play a crucial role in advancing defense capabilities through innovation and collaboration with government agencies. By leveraging […]

Agile Electronic Contract Manufacturing for Defense

August 23, 2024

In today’s constantly changing environment of defense technology, agility isn’t just a desirable trait; it’s an absolute necessity. With adversaries continually innovating and the requirements of modern warfare shifting rapidly, the ability to adapt quickly is essential. Electronic contract manufacturing is pivotal in this dynamic environment, ensuring defense systems remain at the cutting edge. This […]

Challenges and Solutions in Securing the Supply Chain for Defense Electronics

August 19, 2024

In a time when technology skills and worldwide competition are critical, protecting the supply chain for defense electronics is crucial for national security. From fighter jets to communication systems, the reliability and integrity of defense electronics are essential for military operations. However, ensuring the safety and resilience of these supply chains presents a host of […]

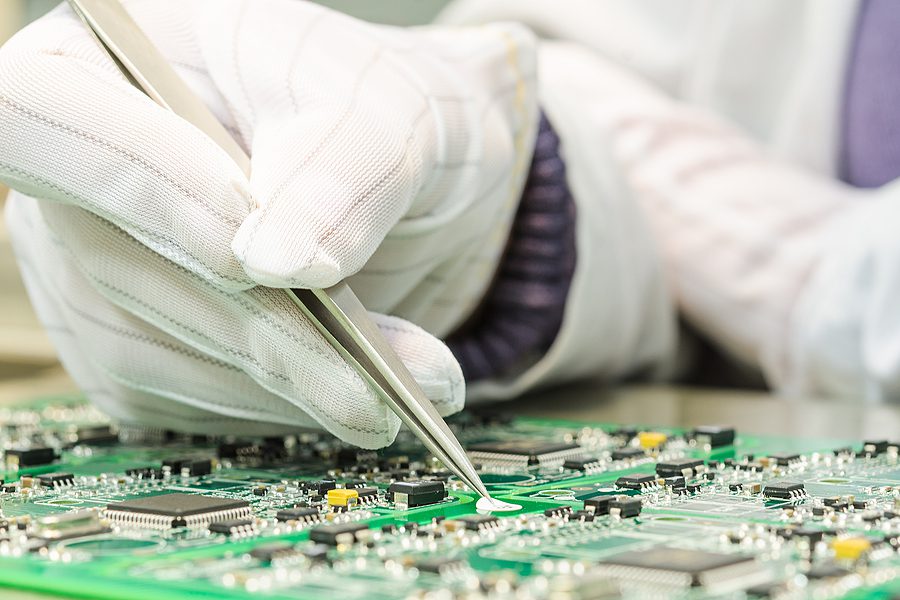

Customization in Electronic Manufacturing: Meeting Diverse Client Needs

August 16, 2024

In today’s rapidly evolving technological landscape, the demand for electronic devices spans many industries, each with its unique requirements and challenges. Businesses increasingly seek customized electronic manufacturing solutions tailored to their needs, from healthcare to automotive, consumer electronics to aerospace. This article will explore the significance of customization in electronic manufacturing and how our company […]

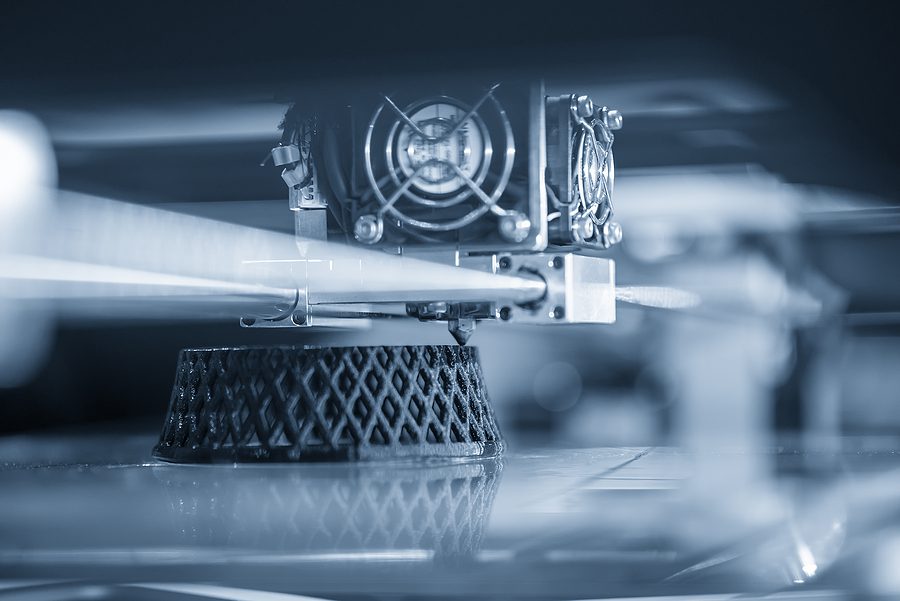

Sustainability Practices in Electronic Manufacturing

August 12, 2024

In the era of rapidly advancing technology, the demand for electronic devices continues to soar, shaping our daily lives profoundly. However, producing these devices often comes with a significant environmental cost. The electronic manufacturing industry faces sustainability challenges, from resource depletion to electronic waste. Despite these hurdles, companies worldwide increasingly embrace eco-friendly practices to mitigate […]

Innovation in Medical Device Manufacturing: A Look into ISO 13485 Certification

August 9, 2024

In the continuously changing field of medical device production, where precision, safety, and regulatory adherence are of utmost importance, maintaining rigorous quality standards isn’t merely advisable—it’s imperative. Among the myriad of certifications available, ISO 13485 stands out as a cornerstone of excellence, providing manufacturers with a robust framework for ensuring quality control, meeting regulatory requirements, […]