Benefits of Reverse Engineering in Test and Measurement Contract Electronic Manufacturing

Manufacturing quality counts when it comes to test and measurement instruments. Technology is constantly evolving and improving, which allows for even more accurate products. Perhaps your devices need an upgrade. Or maybe you just need to increase the speed and accuracy of your instruments. If so, there is no need to go back to the drawing board. Reverse engineering can help. Working with an electronic manufacturer that utilizes the reverse engineering process can get your mechanical instruments upgraded and performing as advanced electronics without the time, money, and stress of developing an entirely new product.

What is Reverse Engineering?

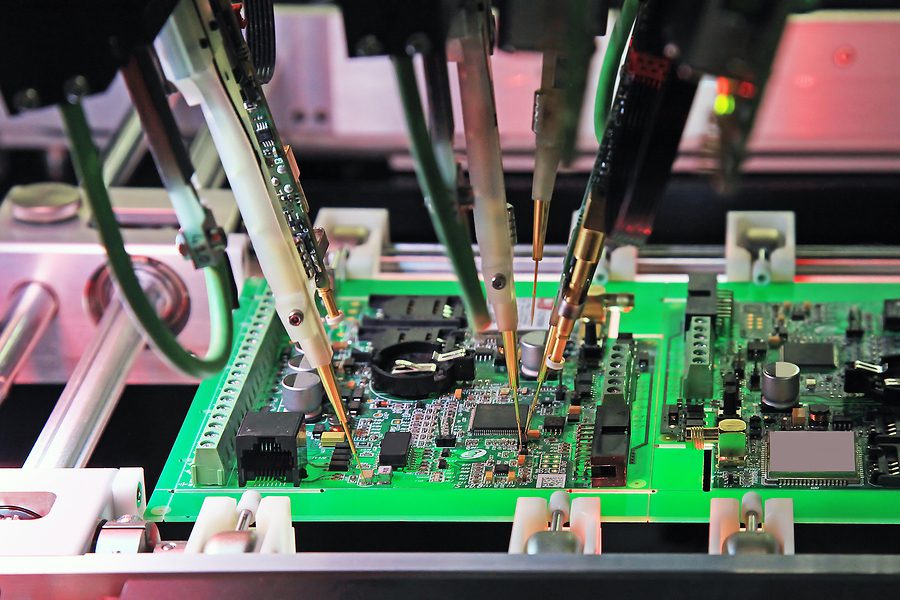

The reverse engineering process involves taking a product apart to reveal its original design and discover what makes it work. The goal is to uncover as much about an item as possible in order to duplicate and/or enhance it. It is especially useful if you have an already proven product. As you understand the product, you can begin to see where improvements or substitutions can be made. In the case of parts obsolescence, it allows you to substitute or fabricate a new part that meets the same specs. The reverse engineering process can also be used when repairs are needed in cases such as missing PCB layouts or damaged circuits.

Save Time and Money by Not Starting from Scratch

Developing new products is a huge undertaking. Reverse engineering can streamline the process without cutting corners or compromising quality. Utilizing it can speed up the time it takes to get your product to market. Designers and engineers can look at your product and instantly begin to tweak and troubleshoot it. They can identify what parts make it work and see if money-saving substitutions can be made. They can also suggest alternatives that will minimize assembly. This can save you in time, shipping, and more.

Update a Legacy Product

Sometimes it is hard to see when a legacy product is ready for a revamp. The reverse engineering process can help you identify where there is room for improvement. Engineers will find ways to make it work more efficiently and increase the performance of your already successful product. Reverse engineering can step in when designs for your legacy product are no longer available. By doing so, your ECM can determine how your legacy components work and how to update them to modern technology so your device can work smarter and faster.

On-site Engineers can Improve Function and Design

Reverse engineering is a great way to make a product more efficient and last longer. Once a product is stripped down, it is easy to see how a design can be updated and streamlined. If the company you hire to complete the reverse engineering process has on-site engineers, they will be able to step in immediately and start tweaking areas that can be modernized and improved. As a result, an even better product will be delivered to your customers.

Email SalesReverse Engineering Isn’t Fixing What’s Not Broken

It is seizing the opportunity to take your product to the next level. Levison Enterprises can help you achieve this. We use the reverse engineering process to make your test and measurement device the best it can be while saving you time and money. If you need test and measurement assembly and manufacturing services, look no further than Levison. Contact our team today to see what reverse engineering can do for you.