Benefits of a Flexible Printed Circuit Board Design in Electronic Manufacturing

Rigid printed circuit boards are just fine for a number of applications, but depending on how you choose to utilize the PCBs, your electronic manufacturer may need to take it to the next level. That’s when flexible PCBs enter the picture – they give you the ability to really custom-tailor your next PCB project, moving innovation and design forward.

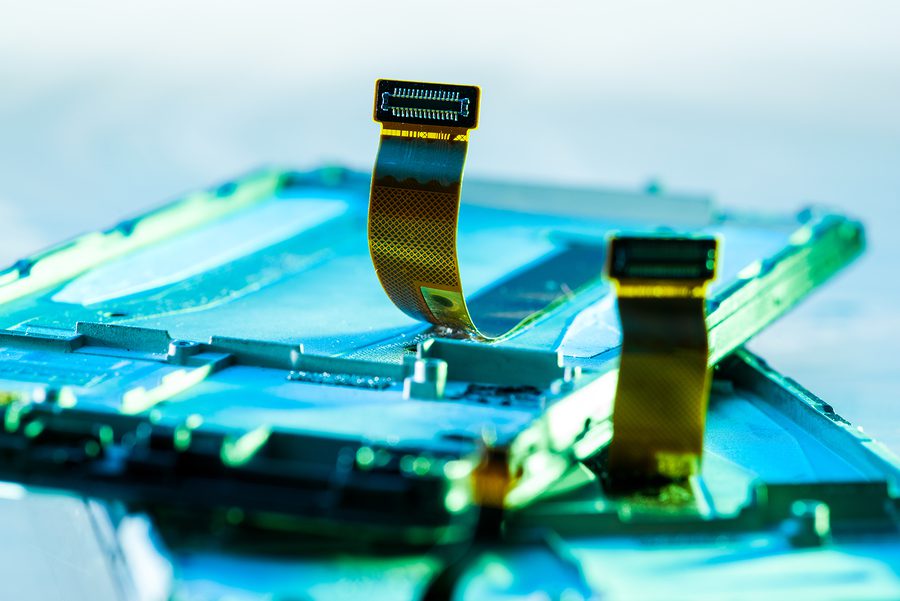

The technology involved in flexible PCBs, also called flex circuits, has evolved rapidly, as has the need. There are many different types of flexible PCBs, giving manufacturers the ability to adapt them to many specific needs.

Makeup of Flexible PCBs

Of course, one of the biggest hurdles in designing flexible PCBs has been the very nature of how PCBs are deployed, especially in the aerospace and defense industries. No matter whether the PCB is rigid or flexible, it needs to be designed to withstand whatever conditions may be thrown at it. Big swings in ambient or operating temperatures, vibration, and moving parts all around the PCB mean that at its core, it must be able to withstand extreme conditions.

The lightweight nature of PCBs in general seems to stand in direct conflict. However, flexible PCBs can actually give manufacturers a leg up in the fight. Even though they are composed of thin, flexible materials, those same materials also give the flexible PCB a high degree of bend-ability, strength, and overall flexibility.

Advantages of Flexible PCBs

Flexible PCBs have given designers and engineers the ability to increasingly drive tech towards smaller form factors. Whether it’s a satellite bound for orbit or a consumer-level MP3 player, flexible PCBs allow circuits to be routed through tight spaces yet still maintain their integrity.

Flexible PCB advantages go beyond the intrinsic ability to bend and flex, however. Giving designers and engineers greater adjustability can also mean tailoring designs to increase airflow, which can keep operating temperatures down. Flexibility also gives the PCB a better ability to withstand excessive vibration. Form factors are also positively impacted. Less material means less weight, and in certain applications that can make a big difference in performance overall.

Connectedness of flexible PCBs has also improved. The circuits employed with flexible PCBs are capable of ultra-high wiring density, therefore taking up less internal space than traditional wiring harnesses. Flexible connect-ability also means a greatly reduced human error factor that exists with traditional PCB assemblies since they don’t need to be manually connected.

Perhaps the biggest advantage to a flexible PCB solution is the lowered cost of ownership. The absence of board-to-board connections and jumper wires give designers the ultimate freedom to design a board that does what it is supposed to do, without making compromises necessary when utilizing rigid PCBs.

At Levison Enterprises, we’ve been working with flexible PCBs long enough to know the distinct advantages they deliver for our customers. If you think they might be the right fit for your next project, contact our experienced team to learn more.

Start Your Quote Now!