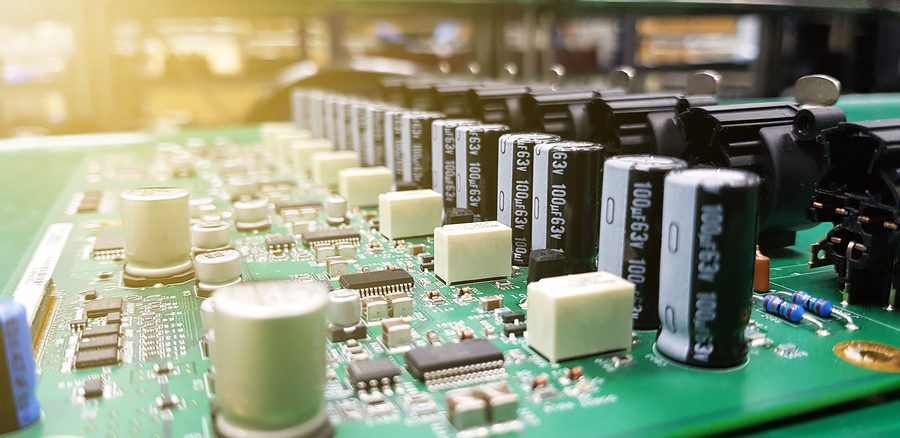

Avoiding 3 Common Problems During PCB Manufacturing Process

PCB manufacturing isn’t rocket science, but it does take some attention to detail. The design and quality of printed circuit boards directly affect how well the boards work in the final product. Designing and manufacturing PCBs can be a complex process. There is a risk of PCB failure as a result of oversights while a project is prepped for production. Luckily, most issues can be avoided by being aware of the most common PCB manufacturing problems. Being aware of these issues and the best ways to prevent them can save you from a PCB catastrophe.

Problem 1: Missing or Incomplete Gerber Files

A big problem with PCB manufacturing is when Gerber files are incomplete or missing. Gerber files are basically digital blueprints that are used by your ECM during the fabrication process. It is the outline of everything that needs to be done. Gerber files digitally tell how and where every component needs to be placed, how big and where each hole must be drilled, and what tool will be used on every layer of your PCB. Without this complete information, the PCB manufacturing process can and will fail. A single error in a Gerber file will throw off the entire design resulting in printed circuit boards that don’t work at all.

Problem 2: Accounting For All Parts In BOM

Omitting parts on the bill of materials (BOM) is another major pitfall that can mess up PCB manufacturing. An accurate BOM provides details on all the parts required to build a shippable product. If an item needs to be purchased, processed, or inventoried to make the PCB, it must be on the BOM. For a manufacturing BOM, the components would be listed by how the PCB will be assembled. Without all of this represented on your bill of materials, your PCB is at risk of being built slowly, incorrectly, or not at all.

Problem 3: Taking User Environment Into Account

To manufacture a successful PCB, you must take its end use into account. Your PCB will need to stand up to various environmental factors when placed in the final product. This must be considered during the design and manufacturing stage. Will the PCB be exposed to heat, cold, dust, moisture, or temperature swings? All of this can affect PCB performance. Temperature fluctuations can cause elements to expand or contract. This can warp and damage the board and soldering joints. Moisture can lead to oxidation, corrosion, and rust. This can also cause a PCB to overheat by clogging the board. Keeping all of this in mind can hold PCB failure at bay.

Combat These Problems with a DFM

The most common PCB manufacturing problems can easily be avoided with a Design for Manufacturability (DFM) analysis. A DFM will carefully inspect the printed circuit board’s layout to detect and minimize issues that could crop up during production. The DFM will not just look at how the board will work, but how it could potentially break. As a result, any potential errors will be corrected before assembly resulting in a properly functioning PCB. A successful DFM will save time and money by catching design errors ahead of time and preventing manufacturing issues. It will also give you peace of mind by ensuring you have a complete set of Gerber files for manufacturing.

Levison Enterprises specializes in reliable DFM analysis. With more than 100 years of combined experience covering the last several decades of electronics technology and testing protocols, we are confident we can help you build a better PCB. Contact Levison today to learn more about our DFM analysis services.